Waterborne acrylic acid modified epoxy basalt scale anticorrosive paint

A water-based acrylic and epoxy basalt technology, used in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as easy aging and yellowing, and achieve enhanced corrosion resistance, good applicability, and good acid and alkali resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

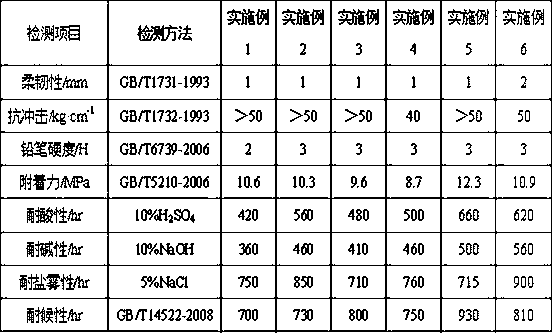

Examples

Embodiment 1

[0025] Accurately weigh 30g of water-based acrylic modified epoxy emulsion, add 40g of deionized water at a stirring rate of 1000r / min, stir for 5min until uniform, then add 0.1g of defoamer TEGO810, 0.1g of leveling agent TEGO450, 0.3g of Deqian FN265 dispersant and 1g Deqian FA179 anti-flash rust agent, stir for 10min. Then weigh 15g of basalt flakes and 5g of aluminum tripolyphosphate and add them into the above emulsion and continue to stir for 30min to obtain component A. Weigh 4.575g of water-based aliphatic isocyanate curing agent and the spare Part A emulsion and mechanically stir until uniform, then make a sample, maintain it at room temperature for one week, and test its performance.

Embodiment 2

[0027] Accurately weigh 50g of water-based acrylic modified epoxy emulsion, add 50g of deionized water at a stirring rate of 2000r / min, stir for 10min until uniform, add 0.2g of defoamer TEGO810, 0.1g of leveling agent TEGO450, 0.3g of Deqian FN265 dispersant and 0.8g Deqian FA179 anti-flash rust agent, stir for 10min. Then weigh 10 g of basalt flakes and 6 g of aluminum tripolyphosphate and add them to the above emulsion and stir for 30 minutes to obtain component A. Weigh 12g of water-based aromatic isocyanate curing agent and the spare Part A emulsion and mechanically stir until uniform to uniform, then make a sample, maintain it at room temperature for one week, and test the performance.

Embodiment 3

[0029] Accurately weigh 65g of water-based acrylic modified epoxy emulsion, add 30g of deionized water at a stirring rate of 2000r / min, stir for 10min until uniform, then add 0.5g of defoamer TEGO810, 0.3g of leveling agent TEGO450, 2g of Deqian FN265 Dispersant and 1.0g Deqian FA179 anti-flash rust agent, stir for 10min. Then weigh 20 g of basalt flakes and 10 g of aluminum tripolyphosphate and add them into the above emulsion and stir for 30 minutes to obtain component A. Weigh 25.76g of water-based aromatic isocyanate curing agent and the spare Part A emulsion and mechanically stir until uniform, then make a sample, maintain it at room temperature for one week, and test its performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com