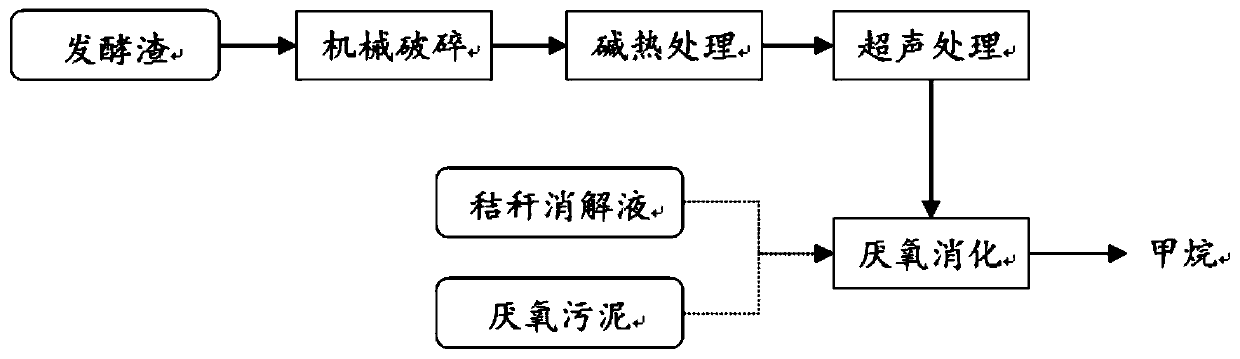

A kind of anaerobic digestion treatment method of antibiotic fermentation residue

A technology of anaerobic digestion and treatment method, applied in the directions of fermentation, biosynthesis, waste fuel, etc., can solve the problems of high biological toxicity of antibiotics, high treatment cost, low disposal capacity, etc., achieve good economy and promotion value, reduce disposal , the effect of reducing the production of ammonia inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Obtained lincomycin fermentation residue from a pharmaceutical factory, the total organic carbon content is 34.4%, the total nitrogen content is 3.16%, and the lincomycin content is 3043mg / kg. First, a knife grinder is used to crush the fermentation residue to below 50 mesh, and then clean water is added to adjust the solid content of the fermentation residue to 20% for later use. The fermentation residue was treated with alkaline heat and ultrasound respectively, and a total of 4 treatment groups were set up. The CK group is the control group, which does not undergo any treatment; the A group is the single-alkali heat treatment group, with 0.05mol / L NaOH, and the digestion is at 130°C for 30 minutes; the B group is the single ultrasonic treatment group, and the ultrasound frequency is set to 25kHz. The preferred energy input is 10000kJ / kg; Group C is the alkali heat treatment + ultrasonic treatment group, add 0.05mol / L NaOH, digest at 130°C for 30 minutes, and then perf...

Embodiment 2

[0044] Obtain the oxytetracycline fermentation residue from a pharmaceutical factory, the total organic carbon content is 41.5%, the total nitrogen content is 4.58%, and the oxytetracycline content is 4289mg / kg. First, use a knife grinder to crush the fermentation residue to below 50 mesh, then add clear water to adjust the solid content of the fermentation residue to 30% and add 0.20mol / L of Ca(OH) 2 , Digestion in an autoclave at 120°C for 60 minutes, let cool, and then perform ultrasonic treatment. The ultrasonic sound energy density is 2w / ml, and the treatment time is 30min. After the above treatment, the concentration of organic carbon in the supernatant of the fermentation residue reaches At 17269mg / kg, the concentration of total nitrogen reached 2215mg / kg, and the concentration of oxytetracycline dropped to 351mg / kg.

[0045] Use the pretreated fermentation residue for anaerobic digestion, inoculate 20% of the anaerobic sludge collected in the paper mill, and add 15% straw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com