Sand lining tooth-shaped pile with excellent performance and construction method thereof

A technology of sand lining and tooth shape, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of serious soil squeezing effect and inability to guarantee construction quality, so as to save excavation earth and stone volume, significant bearing capacity, and start construction The effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

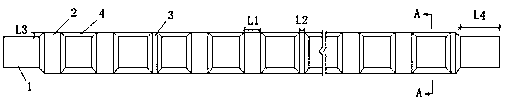

[0040] Such as figure 1 As shown, the sand-lined tooth-shaped pile with excellent performance in this embodiment includes a pile body 1, a through hole is provided in the middle of the pile body 1, and several trapezoidal teeth are arranged at intervals on the pile body 1, and the trapezoidal teeth include trapezoidal wide teeth 2 and trapezoidal teeth. The narrow teeth 3 are alternately distributed in two trapezoidal wide teeth 2 and one trapezoidal narrow tooth 3 .

[0041] The tooth top width L1 of the trapezoidal wide tooth is 100~250mm, and the tooth top width of the narrow tooth is L2=50~80mm. The center distance between each trapezoidal tooth is 300-800mm. The two hypotenuses of the trapezoidal teeth form an angle of 45 degrees with the pile body, and the tooth height L3 of the trapezoidal teeth is 50~60mm. The sand-lined toothed pile also includes vertical ribs 4 arranged on the upper and lower surfaces of the pile body. The height of the vertical ribs is the same as...

Embodiment 2

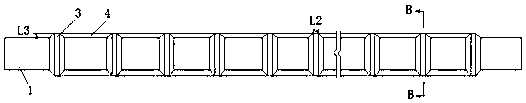

[0046] Such as figure 2 As shown, the sand-lined tooth-shaped pile of this embodiment includes a pile body 1, and several trapezoidal teeth are arranged at intervals on the pile body 1. The trapezoidal teeth are trapezoidal narrow teeth 3, and the center distance between each trapezoidal tooth is 300~800mm .

[0047] The sand-lined toothed pile also includes vertical ribs 4 arranged on the upper and lower surfaces of the pile body. The height of the vertical ribs is the same as the tooth height of the trapezoidal teeth. The tooth height L3 of the trapezoidal teeth is 50~60mm. Figure 5 shown. The addendum width L2 of the narrow tooth is 50~80mm. The two hypotenuses of the trapezoidal teeth form an included angle of 45 degrees with the pile body. The distance between the two ends of the pile body 1 and the trapezoidal teeth at both ends is 500mm. The total length of the sand-lined toothed pile is L=12~13m.

[0048] The obtuse angle formed by the trapezoidal hypotenuse and...

Embodiment 3

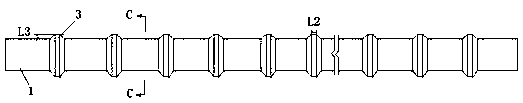

[0052] Such as image 3 As shown, in the sand-lined tooth-shaped pile of this embodiment, vertical ribs 4 are not arranged on the upper and lower surfaces of the pile body, and the rest are the same as in Embodiment 2. The C-C sectional view is as follows Figure 5 shown.

[0053] In the construction method of the above-mentioned sand-lined tooth-shaped piles involved in this embodiment, a long auger drill with the same diameter and the full length of the pilot hole is first used, and then the pile is pressed by a vibrating machine, and the depth of the pile is 12-15m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com