Palladium-ruthenium nano-thorn assembly catalyst and preparation method thereof

A nanothorn and assembly technology, which is applied in the field of palladium ruthenium nanothorn assembly catalyst and its preparation, can solve the problems of complexity, difficulty in large-scale preparation, time-consuming, etc., and achieve simple preparation method, high yield and high application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method of a palladium ruthenium nanothorn assembly catalyst, said method comprising the steps of:

[0039] 1) Prepare respectively sodium chloropalladate and ruthenium chloride with a concentration of 20mM, a hydrochloric acid solution with a concentration of 6M and an ascorbic acid solution with a concentration of 0.1M;

[0040]2) Mix 0.4mL sodium chloropalladate and 2.6mL ruthenium chloride solution, then add 0.1 mL hydrochloric acid solution, then add 80mg potassium bromide and 50mg F127, and mix evenly by ultrasonic; finally add 2mL ascorbic acid solution, and mix by ultrasonic 10 minutes;

[0041] 3) After the solution is fully mixed, place it in an oil bath and heat it to 90° C., react for 1 hour, wash, centrifuge, and dry to obtain the palladium ruthenium nanothorn assembly catalyst.

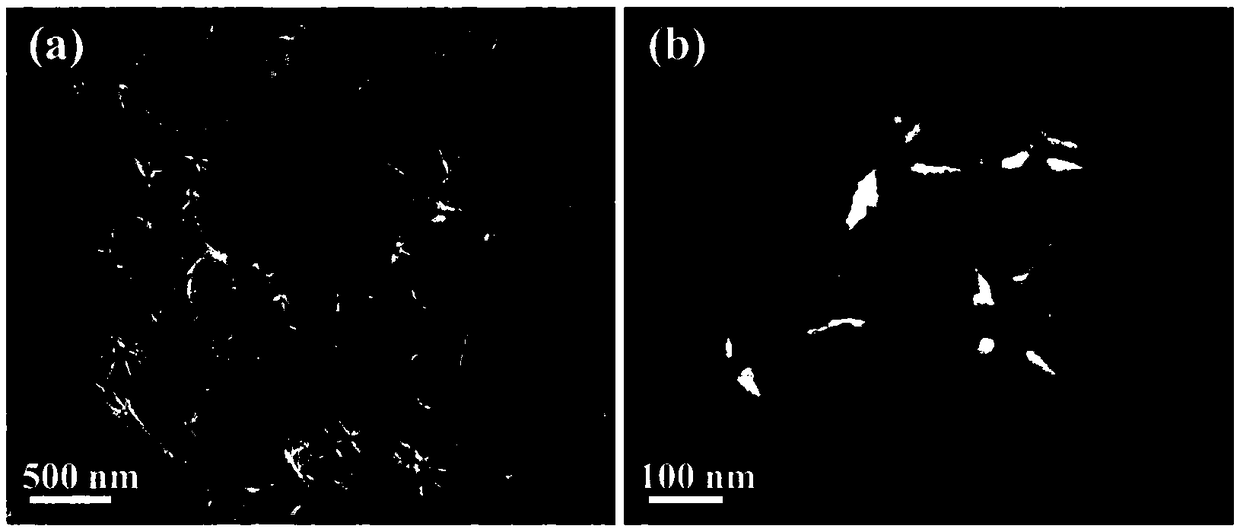

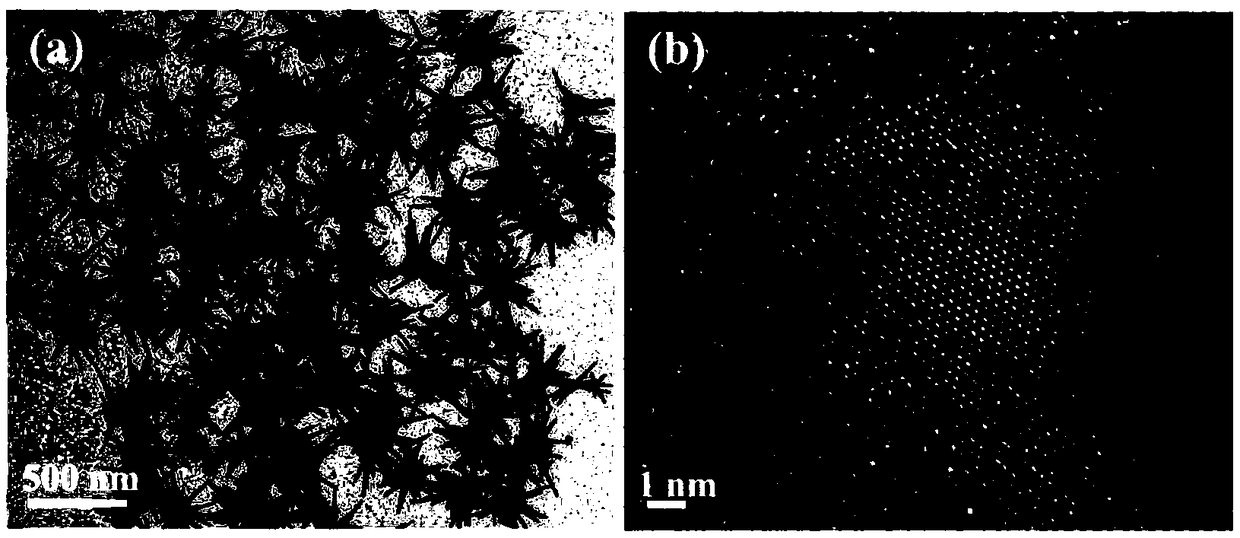

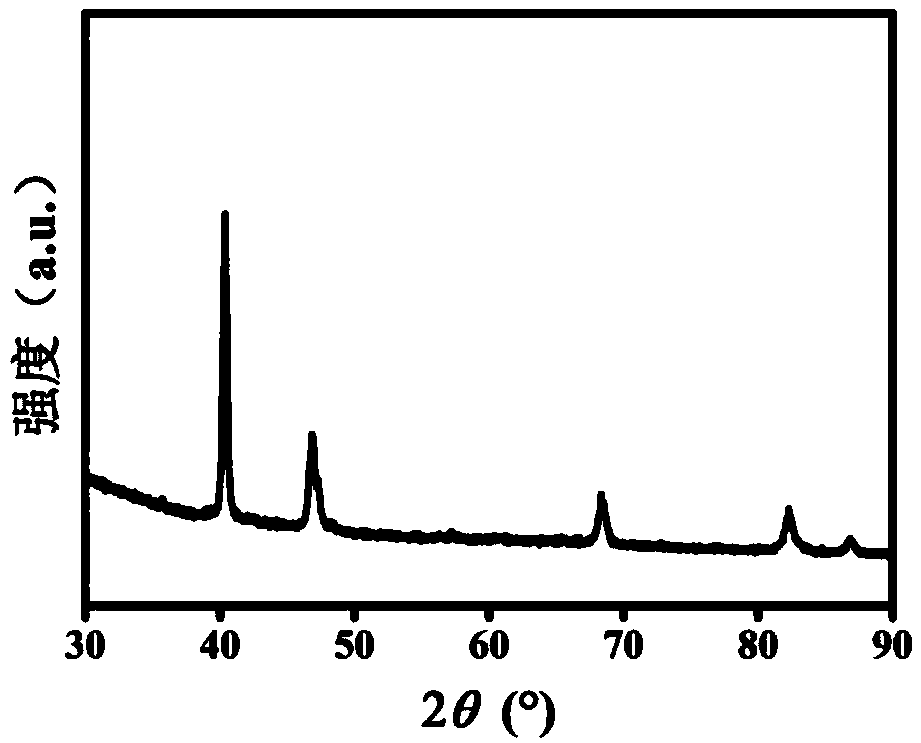

[0042] The SEM figure of the obtained palladium ruthenium nanothorn assembly catalyst is shown in figure 1 . The TEM figure of the obtained palladium ruthenium nan...

Embodiment 2

[0045] A preparation method of a palladium ruthenium nanothorn assembly catalyst, said method comprising the steps of:

[0046] 1) Prepare respectively sodium chloropalladate and ruthenium chloride solutions with a concentration of 20mM, a hydrochloric acid solution with a concentration of 6M and an ascorbic acid solution with a concentration of 0.1M;

[0047] 2) Mix 1.5mL sodium chloropalladate and 1.5mL ruthenium chloride solution respectively, then add 0.1 mL hydrochloric acid solution, then add 80mg potassium bromide and 50mg F127, and mix well by ultrasonic. Finally, 2 mL of ascorbic acid solution was added, and ultrasonically mixed for 10 minutes;

[0048] 3) After the solution is fully mixed, place it in an oil bath and heat it to 90° C., react for 1 hour, wash, centrifuge, and dry to obtain the palladium ruthenium nanothorn assembly catalyst.

[0049] Obtain the SEM image of palladium ruthenium flower-shaped nanoparticles see Figure 7 .

[0050] It can be seen from...

Embodiment 3

[0052] A preparation method of a palladium ruthenium nanothorn assembly catalyst, said method comprising the steps of:

[0053] 1) Prepare respectively sodium chloropalladate and ruthenium chloride with a concentration of 20mM, a hydrochloric acid solution with a concentration of 6M and an ascorbic acid solution with a concentration of 0.1M;

[0054] 2) Mix 0.2 mL of sodium chloropalladate and 2.8 mL of ruthenium chloride solution, then add 0.2 mL of hydrochloric acid solution, then add 80 mg of potassium bromide and 50 mg of F127, and mix well by ultrasonic. Finally, 2 mL of ascorbic acid solution was added, and ultrasonically mixed for 10 minutes;

[0055] 3) After the solution is fully mixed, place it in an oil bath and heat it to 90° C., react for 1 hour, wash, centrifuge, and dry to obtain the palladium ruthenium nanothorn assembly catalyst.

[0056] Obtain the SEM image of palladium ruthenium nanoparticle see Figure 8 .

[0057] It can be seen from the SEM image that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com