Preparation and application of bismuth vanadate hollow nanostructure modified by bismuth quantum dots

A technology of nanostructure and quantum dots, which can be used in the separation of dispersed particles, air quality improvement, gas treatment, etc., can solve the problems of difficult industrial production, high price, and low reserves, and achieve wide application, low price, and large specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0044] Hollow pie Bi 4 V 2 o 11 Preparation: Weigh 1.7mmol (0.8245g) of Bi(NO 3 )·5H 2 Dissolve the O solid in 20ml of ethylene glycol solution, stir and dissolve at room temperature until the solution is clear, and record it as A solution; weigh 0.85mmol (0.1037g) of NaVO 3 Dissolve the solid in 12ml of pure water, stir and dissolve at room temperature until the solution is clear, and record it as solution B; add solution B dropwise to solution A to obtain a yellow clear solution, continue stirring for 30 minutes, and record it as solution C; Transfer to a 50ml reactor, place the reactor in an oven, and react at a high temperature of 180°C for 10h. The brown product obtained after the reaction was washed with water and ethanol, and then transferred to a vacuum drying oven at 50° C. for 6 h.

Embodiment example 2

[0046] Hollow pie Bi 4 V 2 o 11 Preparation: Weigh 1.4mmol (0.6790g) of Bi(NO 3 )·5H 2Dissolve the O solid in 20ml of ethylene glycol solution, stir and dissolve at room temperature until the solution is clear, and record it as A solution; weigh 0.7mmol (0.0854g) of NaVO 3 Dissolve the solid in 12ml of pure water, stir and dissolve at room temperature until the solution is clear, and record it as solution B; add solution B dropwise to solution A to obtain a yellow clear solution, continue stirring for 30 minutes, and record it as solution C; Transfer to a 50ml reactor, place the reactor in an oven, and react at a high temperature of 160°C for 10h. The brown product obtained after the reaction was washed with water and ethanol, and then transferred to a vacuum drying oven at 50° C. for 6 h.

Embodiment example 3

[0048] Hollow pie Bi 4 V 2 o 11 Preparation: Weigh 2.0mmol (0.97g) of Bi(NO 3 )·5H 2 Dissolve the O solid in 20ml of ethylene glycol solution, stir and dissolve at room temperature until the solution is clear, and record it as A solution; weigh 1.0mmol (0.1220g) of NaVO 3 Dissolve the solid in 12ml of pure water, stir and dissolve at room temperature until the solution is clear, and record it as solution B; add solution B dropwise to solution A to obtain a yellow clear solution, continue stirring for 30 minutes, and record it as solution C; Transfer to a 50ml reactor, place the reactor in an oven, and react at a high temperature of 200°C for 10h. The brown product obtained after the reaction was washed with water and ethanol, and then transferred to a vacuum drying oven at 50° C. for 6 h.

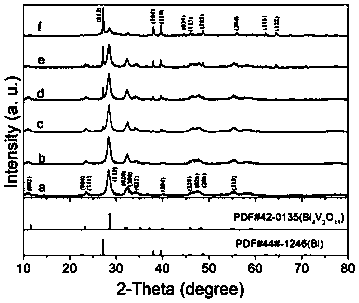

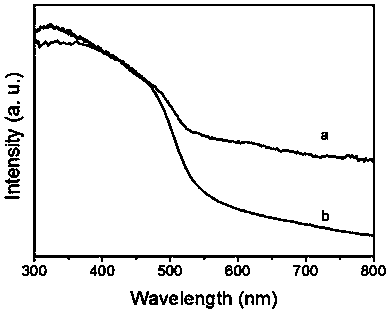

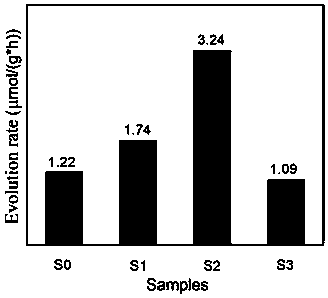

[0049] To the Bi prepared in embodiment 1 4 V 2 o 11 Some crystal structure and morphology studies were performed. Depend on figure 1 As can be seen from the X-ray diffraction (XR...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com