System and method for preparing deuterium-depleted water and deuterium-rich water by separating natural water

A technology of deuterium-depleted water and natural water, applied in the field of water treatment, can solve the problems of complicated control of parameters such as temperature and flow rate, lack of practical application value, low separation efficiency, etc., and achieves low-cost packing, simple structure and flexible operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

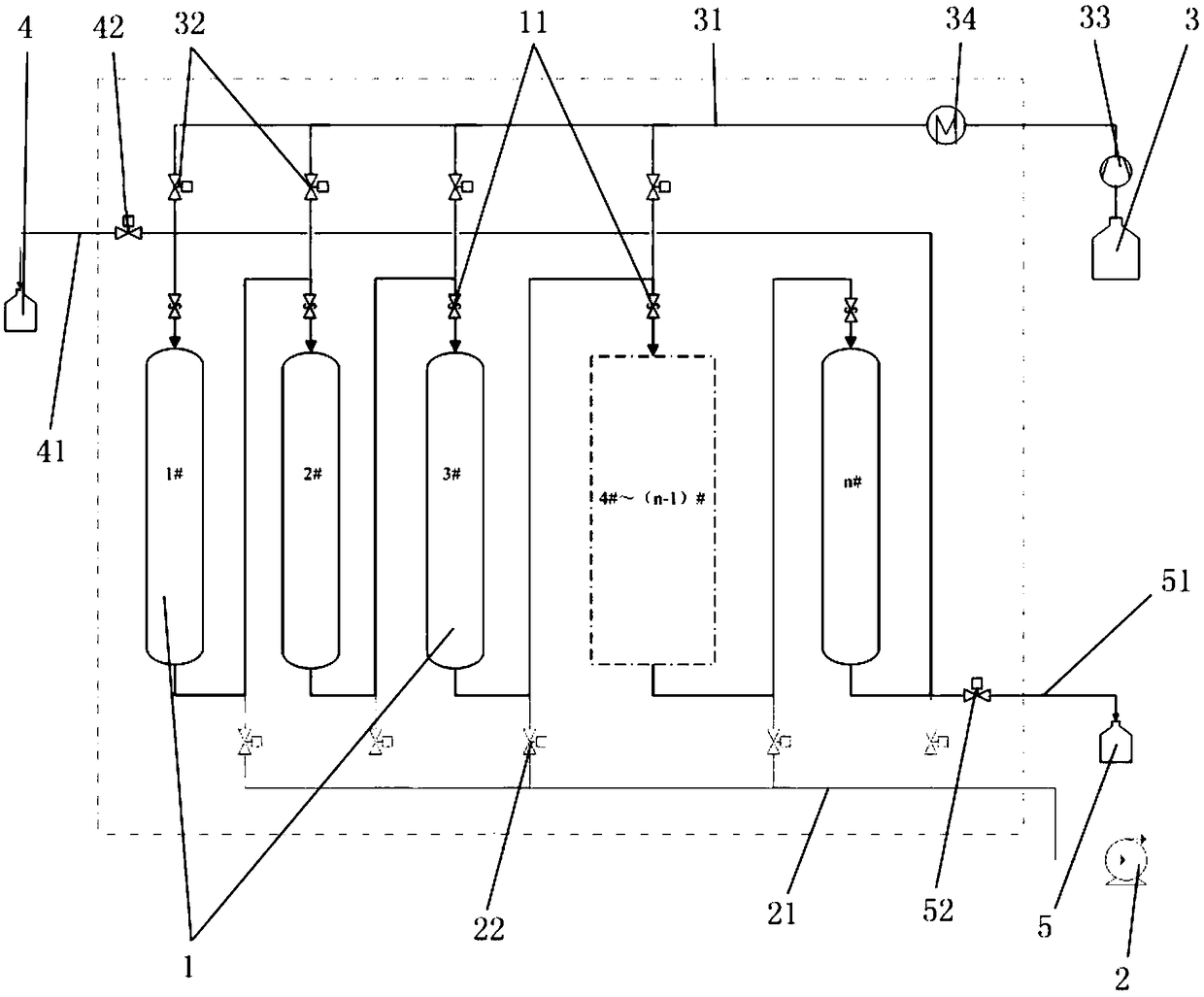

[0036] The purpose of this embodiment is to provide a system for separating natural water to prepare deuterium-depleted water and deuterium-rich water, which not only helps to solve the problem of high cost of preparing deuterium-depleted water by the current distillation method and dual temperature exchange method, but also can be obtained at the same time Deuterium-rich water is used as a raw material for heavy water production.

[0037] A system for separating natural water to prepare deuterium-poor water and deuterium-rich water, such as figure 1 As shown, the system includes a sealed electric heating box, separation components arranged in the electric heating box, and a raw material water storage tank 3, a deuterium-rich water storage tank 4, a deuterium-depleted water storage tank 5 and a vacuum pump arranged outside the electric heating box. The electric heating box is a phenolic foam board box, and a dry-burning electric heating rod is arranged at the bottom of the electr...

example 1

[0052] Example 1: Single-cycle mode, preparation of deuterium-poor water with a deuterium concentration of 80ppm

[0053] The core component of the system for separating natural water to prepare deuterium-poor water and deuterium-rich water of the present invention is 8 separation columns (No. 1-8), and the separation columns are numbered (No. 1 → No. 2 →... → No. 8 → No. 1) The pipeline is connected end to end in turn to form a closed loop; the system also includes a raw water storage tank, a deuterium-rich water storage tank, a deuterium-depleted water storage tank, a metering pump, a vaporizer, a vacuum pump, and the pipes and valves connecting the above devices.

[0054] The separation column, metering pump, vaporizer, and the corresponding connecting pipes and valves are all placed in a sealed electric heating box. The box of the electric heating box is made of phenolic foam board; the bottom of the electric heating box is equipped with a dry-burning electric heating rod, and t...

example 2

[0066] Example 2: Double circulation mode, preparation of deuterium-poor water with a deuterium concentration of 30ppm

[0067] Follow the steps S1 to S4 of Example 1 to complete the first cycle separation;

[0068] Follow the steps S3 to S4 in Example 1 to complete the second cycle separation;

[0069] Then connect the deuterium-rich water storage tank pipeline, heat the No. 1 separation column, discharge the deuterium-rich water from the top of the column, the deuterium-rich water collection volume is about 160g, the deuterium concentration is about 410ppm; connect the deuterium-depleted water storage tank pipeline, and heat No. 7 separation column, drain deuterium-depleted water from the bottom of the column, the collected amount of deuterium-depleted water is about 340g, and the deuterium concentration is about 30ppm.

[0070] Sampling and analysis of the deuterium content of the water vapor in the No. 2 to No. 6 separation columns showed that the No. 4 separation column, which ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com