Preparation method for positive electrode material of lithium sulfur battery

A cathode material, lithium-sulfur battery technology, applied in battery electrodes, lithium storage batteries, non-aqueous electrolyte storage batteries, etc., can solve the problems of small output and complex preparation methods, and achieve improved conductivity, not easy to agglomerate, and excellent cycle stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

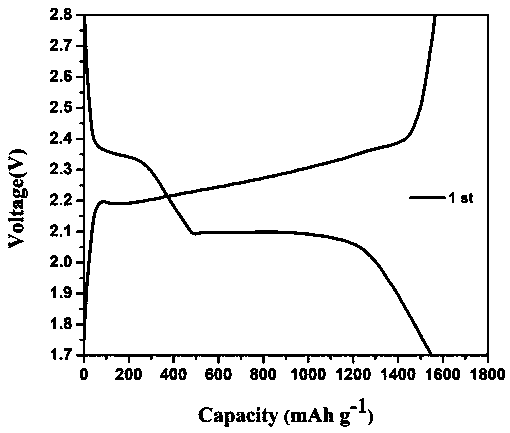

Image

Examples

Embodiment 2

[0034] Step 1: Preparation of ZIF-67@GO / CNTS composite:

[0035] 1455mg of Co(NO 3 ) 2 ·6H 2 O was added to the methanol solution of 125ml and stirred for 10min; the 2-methylimidazole of 1640mg was added to the methanol solution of 125ml and stirred for 10min, and the solution mixed with 2-methylimidazole was slowly poured into the still stirring Co ( NO 3 ) 2 ·6H 2O solution, stirred for 30min and then stood still. After 24 h the solution was centrifuged and dried. Graphene and carbon nanotubes were formulated into a mixed solution with a mass ratio of 1:1. The prepared ZIF-67 was added to the mixed solution with graphene and carbon nanotubes, and the ZIF-67@GO / CNTS composite was prepared by spray drying.

[0036] Step 2: Carbonization of ZIF-67@GO / CNTS composite:

[0037] The ZIF-67@GO / CNTS composite material prepared in the first step was placed in a porcelain boat, and then the porcelain boat was placed in a tube furnace, and the sample was heated at 350°C for 2h ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com