A kind of preparation method of lanthanum zirconate in-situ coating high-nickel ternary positive electrode material

A cathode material and in-situ coating technology, which is applied in the field of modification and preparation of cathode materials for lithium-ion batteries, can solve the problems of not effectively avoiding irreversible capacity loss, reducing surface alkalinity, and consuming lithium residues, etc., to achieve good cycle stability and rate performance, low cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

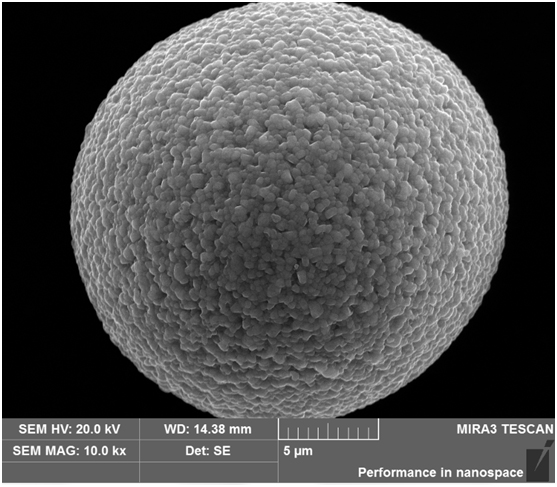

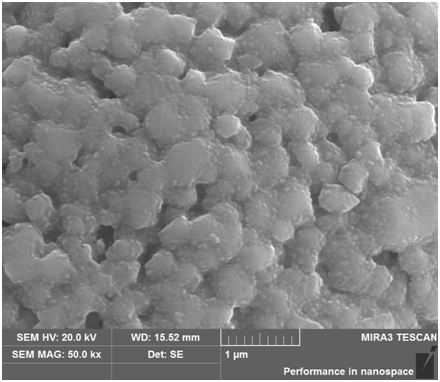

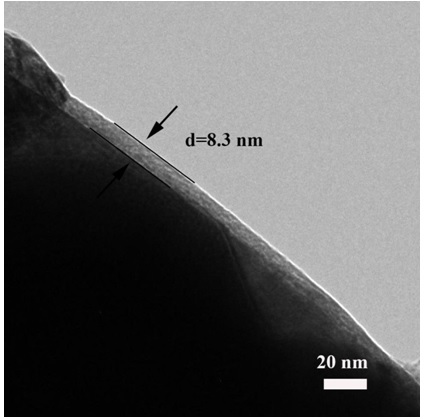

[0045] Lanthanum zirconate prepared in this example coated LiNi in situ 0.8 co 0.1 mn 0.1 o 2 High-nickel ternary positive electrode material, the mass percentage content of the lanthanum zirconate is 1%, and the lanthanum zirconate is in the high-nickel ternary positive electrode material LiNi 0.8 co 0.1 mn 0.1 o 2 The in-situ gradient growth on the surface forms an amorphous coating layer; the positive electrode material is a spherical particle with a particle diameter of 10-12 μm.

[0046] This embodiment includes the following steps:

[0047] (1) Weigh 10.0000g LiNi 0.8 co 0.1 mn 0.1 o 2 Add the powder into absolute ethanol, then add 0.1513g of lanthanum nitrate (hexahydrate) and stir at a stirring rate of 80 rpm for 30min to obtain a black suspension a;

[0048] (2) Disperse 0.1574g of tetrabutyl zirconate (85% by mass) in 40mL of absolute ethanol, and stir at a stirring rate of 80 rpm for 30min until a transparent and uniform solution b is formed;

[0049] (3...

Embodiment 2

[0060] Lanthanum zirconate prepared in this example coated LiNi in situ 0.8 co 0.1 mn 0.1 o 2 High-nickel ternary positive electrode material, the mass percent content of the lanthanum zirconate is 3%, lanthanum zirconate in the high-nickel ternary positive electrode material LiNi 0.8 co 0.1 mn 0.1 o 2 The in-situ gradient growth on the surface forms an amorphous coating layer; the positive electrode material is a spherical particle with a particle diameter of 10-12 μm.

[0061] This embodiment includes the following steps:

[0062] (1) Weigh 10.0000g LiNi 0.8 co 0.1 mn 0.1 o 2 Add the powder into absolute ethanol, add 0.4539g of lanthanum nitrate (hexahydrate) and stir at a stirring rate of 900 rpm for 10min to obtain a black suspension a;

[0063] (2) Add 0.4722g of tetrabutyl zirconate (85% by mass) into 80mL of absolute ethanol, and stir at a stirring rate of 900 rpm for 10min until a transparent and uniform solution b is formed;

[0064] (3) Add suspension a t...

Embodiment 3

[0072] Lanthanum zirconate prepared in this example coated LiNi in situ 0.8 co 0.1 mn 0.1 o 2 High-nickel ternary positive electrode material, the mass percent content of the lanthanum zirconate is 10%, and the lanthanum zirconate is contained in the high-nickel ternary positive electrode material LiNi 0.8 co 0.1 mn 0.1 o 2 The in-situ gradient growth on the surface forms an amorphous coating layer; the positive electrode material is a spherical particle with a particle diameter of 10-12 μm.

[0073] This embodiment includes the following steps:

[0074] (1) Weigh 10.0000 g LiNi 0.8 co 0.1 mn 0.1 o 2 Add the powder into anhydrous methanol, then add 1.513g of lanthanum nitrate (hexahydrate) and stir at a stirring rate of 300 rpm for 20min to obtain a black suspension a;

[0075](2) Add 1.5742g of tetrabutyl zirconate (85% by mass) into 40mL of absolute ethanol, stir at a stirring rate of 300 rpm for 20min until a transparent and uniform solution b is formed;

[0076...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com