Grinding ball for sludge treatment equipment

A technology for sludge treatment and ball grinding, which is applied in the fields of sludge treatment, water/sludge/sewage treatment, and sludge treatment by temperature control. effect, improved dewatering performance, excellent grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

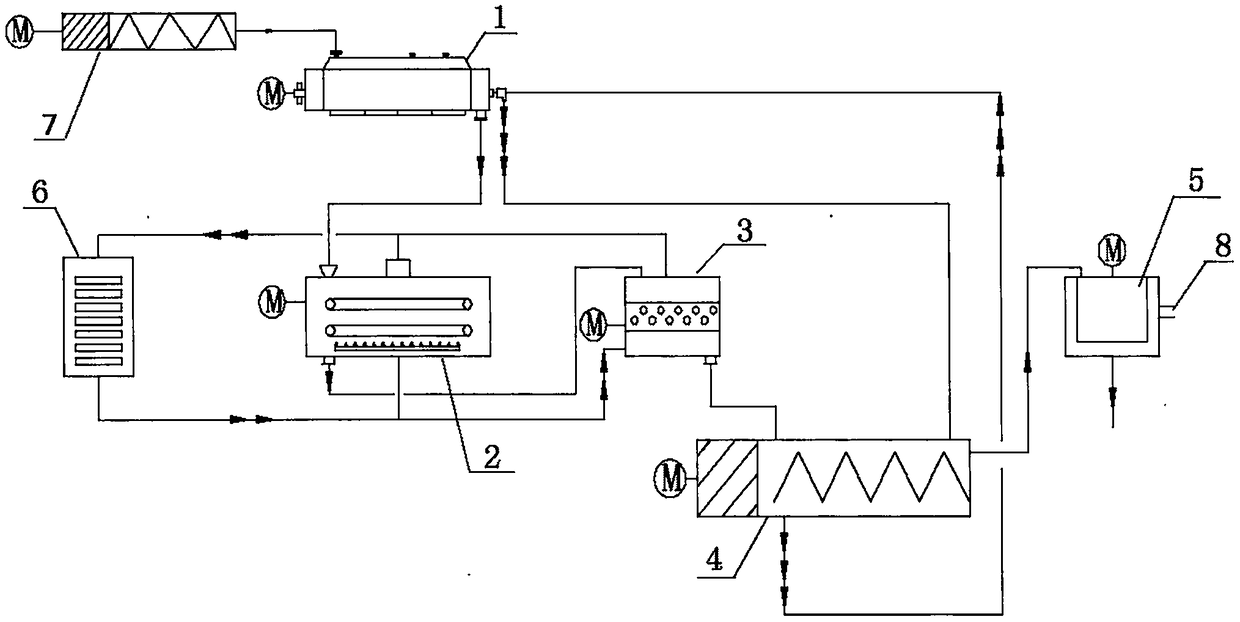

[0026]see figure 1 , a kind of sludge treatment equipment, including paddle sludge cooler 1, belt refrigerator 2, ball mill 3, conveying screw 4, centrifuge 5 connected in sequence, also includes refrigerator 6, sludge pump 7; The sludge cooler is provided with a cooling fluid inlet and a cooling fluid outlet; the freezer is provided with a refrigerated gas inlet and a refrigerated gas outlet (located at the bottom); the ball mill is provided with a cooling gas inlet and a cooling gas outlet, and a grinding ball , the arrangement of grinding balls is conventional; the conveying screw is provided with a heating fluid inlet and a heating fluid outlet; the centrifuge is provided with a clear liquid outlet 8; the refrigerator is provided with an air inlet and an air outlet; the sludge cooling The cooling fluid inlet of the sludge cooler is connected with the heating fluid outlet of the conveying screw, and the cooling fluid outlet of the sludge cooler is connected with the heating...

Embodiment 2

[0029] A kind of sludge treatment equipment, similar to Embodiment 1, including a paddle sludge cooler, a belt refrigerator, a ball mill (with grinding balls), a conveying screw, a centrifuge, a refrigerator, and a sludge pump connected in sequence The freezer is also equipped with a temperature-sensing probe to prevent problems with the key parameters of freezing and breaking the wall, effectively monitor the temperature of the frozen sludge, and ensure the quality of freezing and dewatering.

[0030] The above equipment is used for sludge dewatering: the municipal sludge with a water content of 80% is transported to the sludge cooler by the sludge pump, and the sludge cooler adopts paddle-type cooling equipment to cool down the sludge by indirect heat exchange. , the cooling medium comes from the conveying screw, and after heat exchange and cooling, the temperature of the sludge drops from normal temperature to 10°C. The sludge cooled from the paddle cooler enters the belt f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com