Preparation method of basalt particle reinforced polyurethane hot melt adhesive

A technology of polyurethane hot melt adhesive and basalt particles, which is applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc. problems, to achieve the effect of improving chemical stability, uniform dispersion, and enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

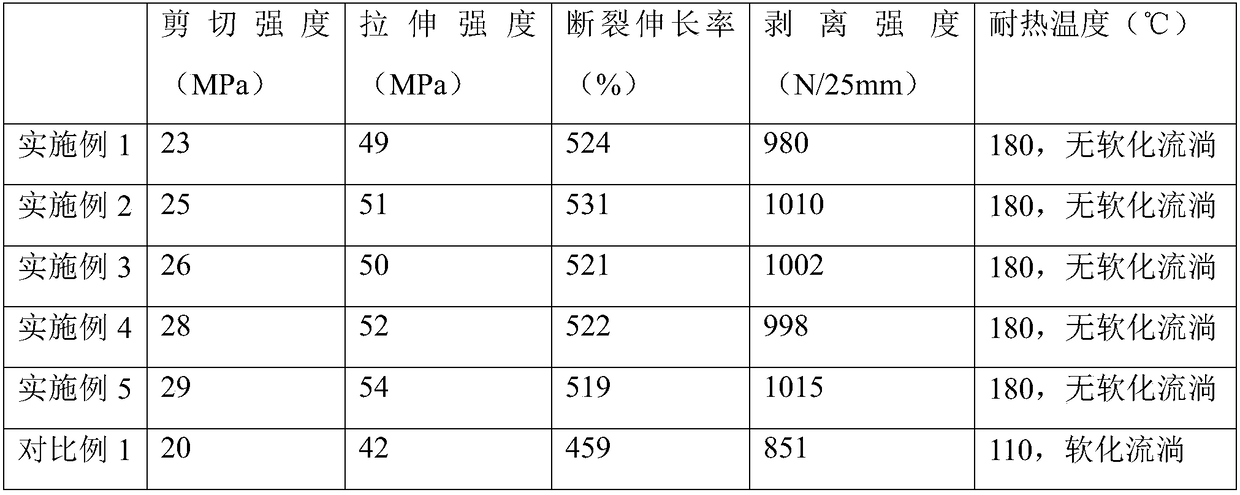

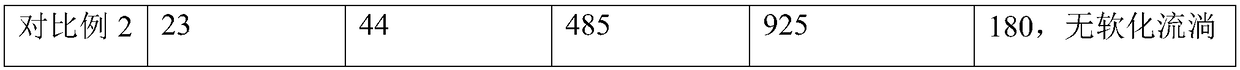

Examples

Embodiment 1

[0016] A preparation method of basalt particle reinforced polyurethane hot melt adhesive, comprising the following steps:

[0017] S1. Put 2500-mesh basalt particles into the planetary ball mill, mix according to the ball-to-material ratio of 4:1, and perform ball milling at a speed of 300r / min, and the effective ball milling time is controlled to 15h;

[0018] S2. Mix the basalt particles after the ball milling in step S1 with the ground microcrystalline cellulose, the mass ratio is 1:1, then add deionized water and stir evenly with magnetic force, then add the catalyst that accounts for 0.5% of the mass of the mixture. Sulfuric acid hexahydrate Ferric ammonium, continue to stir for 10 minutes, and finally react in a hydrothermal reactor at a temperature of 200 ° C for 16 hours, take it out, wash and dry to obtain a basalt / carbon composite material;

[0019] S3. Add an equal volume of stearic acid hot ethanol solution drop by drop while stirring the basalt / carbon composite ma...

Embodiment 2

[0023] A preparation method of basalt particle reinforced polyurethane hot melt adhesive, comprising the following steps:

[0024] S1. Put 4000-mesh basalt particles into the planetary ball mill, mix according to the ball-to-material ratio of 2:1, and perform ball milling at a speed of 500r / min, and the effective ball milling time is controlled to 20h;

[0025] S2. Mix the basalt particles after the ball milling in step S1 with the ground microcrystalline cellulose, the mass ratio is 1:2, then add deionized water and stir evenly with magnetic force, then add the catalyst that accounts for 2% of the mass of the mixture. Sulfuric acid hexahydrate Ferric ammonium, continue to stir for 30 minutes, and finally react in a hydrothermal reactor at a temperature of 250 ° C for 24 hours, take it out, wash and dry to obtain a basalt / carbon composite material;

[0026] S3. Add an equal volume of stearic acid hot ethanol solution drop by drop while stirring the basalt / carbon composite mate...

Embodiment 3

[0030] A preparation method of basalt particle reinforced polyurethane hot melt adhesive, comprising the following steps:

[0031] S1. Put 3000-mesh basalt particles into the planetary ball mill, mix according to the ball-to-material ratio of 2:1, perform ball milling at a speed of 350r / min, and control the effective ball milling time to 20h;

[0032] S2. Mix the basalt particles after the ball milling in step S1 with the ground microcrystalline cellulose, the mass ratio is 1:1, then add deionized water and stir evenly with magnetic force, then add the catalyst that accounts for 1% of the mass of the mixture. Sulfuric acid hexahydrate Ferric ammonium, continue to stir for 20 minutes, and finally react in a hydrothermal reactor at a temperature of 200 ° C for 16 hours, take it out, wash and dry to obtain a basalt / carbon composite material;

[0033] S3. Add an equal volume of stearic acid hot ethanol solution drop by drop while stirring the basalt / carbon composite material, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com