Method for electroplating copper layer on lead frame

A technology of lead frame and electroplated copper layer, which is applied in the field of lead frame electroplated copper layer, can solve the problem of weak bonding between electroplated copper layer and sealing glue, and achieve the effect of increasing the bonding strength and strengthening the degree of firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] This embodiment provides a method for electroplating a copper layer on a lead frame, comprising the following steps:

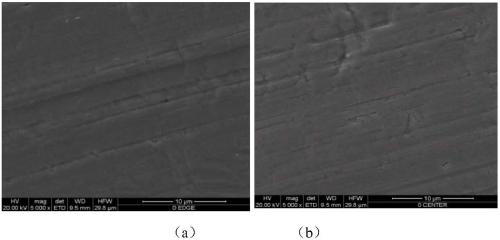

[0063] (1) Degreasing: figure 1 is the scanning electron microscope image of the substrate surface of the lead frame, where figure 1 (a) is a schematic diagram of the surface condition of the central part of the lead frame substrate, figure 2 (b) is a schematic diagram of the surface condition at the edge of the lead frame substrate. Will figure 1The lead frame base material shown was electrolyzed in a PT-200 solution (PT-200 degreasing powder, purchased from Vico Matheson Co., Ltd.) with a concentration of 100g / L, with a current density of 3A / dm and a temperature of 50°C. The electrolysis time is 30s. After degreasing, wash the residue with tap water.

[0064] (2) Activation: at room temperature, soak the base material in the salt solution AS310 for 15s, the concentration of the salt solution is 80g / L, purchased from Zhongshan Anshun metal treatm...

Embodiment 2

[0074] This embodiment provides a method for electroplating a copper layer on a lead frame, which is basically the same as Embodiment 1, except that the bidirectional pulse conditions are as shown in Table 2:

[0075] Table 2

[0076]

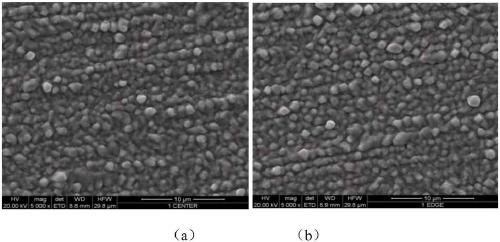

[0077] The scanning electron microscope figure of present embodiment copper layer surface is as image 3 as shown, image 3 (a) is a schematic diagram of the surface condition of the copper layer at the center of the lead frame, image 3 (b) is a schematic diagram of the surface condition of the copper layer at the edge of the lead frame. From image 3 It can be seen that the particle size on the surface of the copper layer in the center is small, the particle size distribution is uniform, and the roughness is small. The space between the surface particles of the copper layer at the edge position is large, the particle size distribution is uneven, and the roughness is large. As a result, when the glue is sealed, the bonding strength betw...

Embodiment 3

[0079] This embodiment provides a method for electroplating a copper layer on a lead frame, which is basically the same as Embodiment 1, except that the bidirectional pulse conditions are as shown in Table 3:

[0080] table 3

[0081]

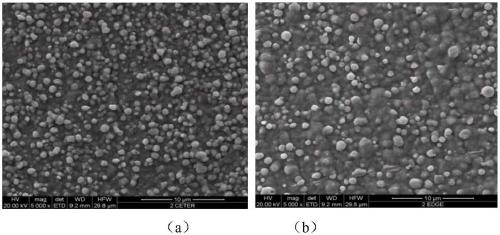

[0082] The scanning electron microscope figure of present embodiment copper layer surface is as Figure 4 shown. Figure 4 (a) is a schematic diagram of the surface condition of the copper layer at the center of the lead frame, Figure 4 (b) is a schematic diagram of the surface condition of the copper layer at the edge of the lead frame. From Figure 4 It can be seen that the particle size of the surface of the copper layer is small and the roughness is small. As a result, when the sealant is sealed, the bonding strength between the metal copper layer and the sealant is weak. After measurement, the thickness of the copper layer in this embodiment is 378.8nm-437.1nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com