Method for grafting hyperbranched polyglycerol on carbon fiber surface based on plasma technology

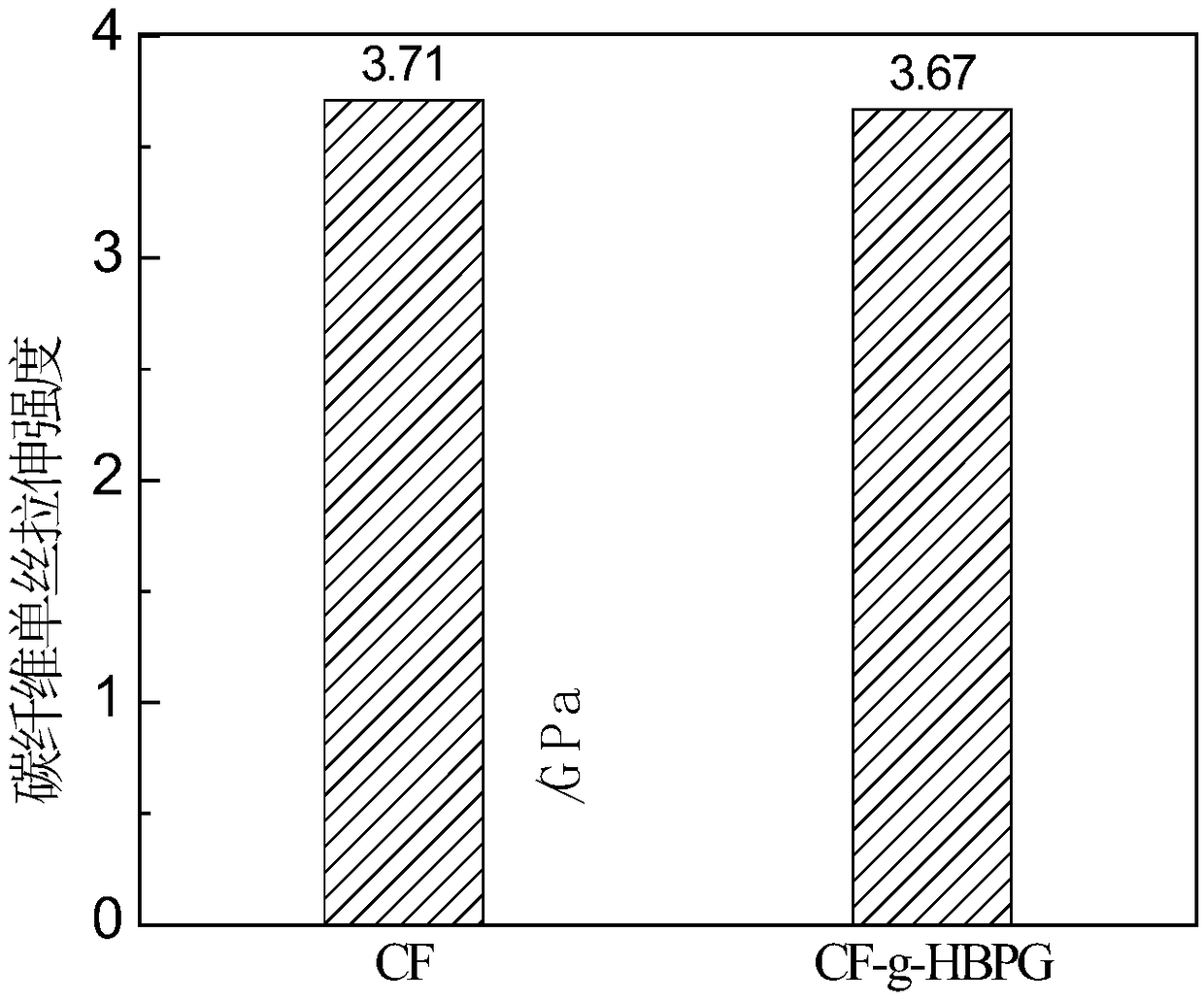

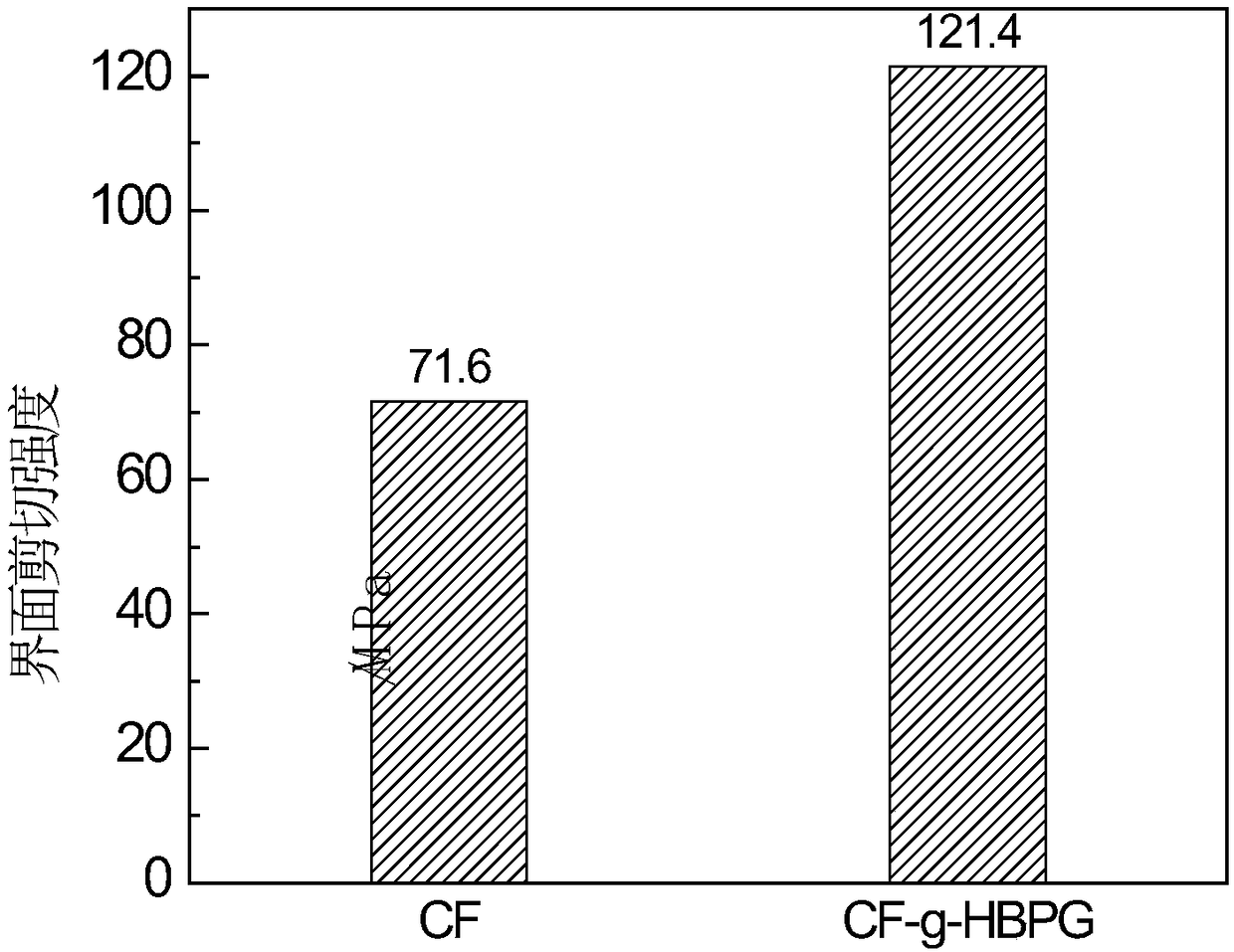

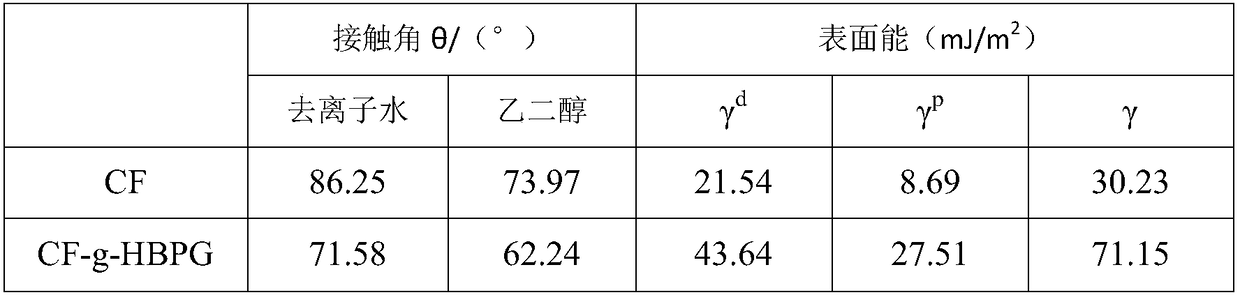

A technology of surface grafting and carbon fiber, which is applied in the direction of carbon fiber, fiber treatment, ultrasonic/sonic fiber treatment, etc., can solve the problems of low resin bonding strength and insufficient surface active groups, and achieve the effect of increasing the probability of grafting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0024] The method for grafting hyperbranched polyglycerol on the carbon fiber surface of this embodiment based on plasma technology is carried out in the following steps:

[0025] Step 1: Removal of epoxy coating on carbon fiber surface

[0026] Put the carbon fiber bundles into a Soxhlet extractor, use acetone as a solvent, and heat at 75°C-85°C, so that the acetone is continuously evaporated and condensed in the Soxhlet extractor, so that the impurities on the surface of the carbon fibers are continuously cleaned in the distilled acetone. The time is 30h-40h; then take out the carbon fiber and dry it in an oven at 80°C-90°C for 4h-6h.

[0027] Step 2: Preparation of plasma-activated carbon fibers

[0028] Put the carbon fiber in the plasma reaction chamber, first pass high-purity argon with a flow rate of 1.5L / min-2L / min for 5min-8min; then pass through pure oxygen with a flow rate of 10mL / min-15mL / min for 5min -8min; Discharge treatment at a power of 60W-80W for 80s-100s ...

specific Embodiment approach 2

[0035] The difference between this embodiment and specific embodiment 1 is that the high-purity argon gas flow introduced in step 2 is 1.5L / min-1.8L / min, and the feeding time is 5min-6min. Others are the same as specific embodiment 1.

specific Embodiment approach 3

[0036] The difference between this embodiment and specific embodiment 1 and specific embodiment 2 is: the flow rate of high-purity oxygen introduced in step 2 is 10mL / min-12mL / min, and the feeding time is 6min-8min. Others are the same as in specific embodiment 1 or Method 2 is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com