Composite negative electrode material for sodium ion batteries and preparation method thereof

A technology of sodium ion battery and negative electrode material, applied in battery electrodes, secondary batteries, electrode carriers/current collectors, etc., can solve the problems of lack of lithium resources, difficulty in maintaining energy demand, etc., to overcome low active surface and increase specific capacity , the effect of increasing energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0048] A preparation method of a composite negative electrode material for a sodium ion battery, comprising the steps of:

[0049] Step a, prepare graphene foam material, stand-by;

[0050] Step b, growing carbon nanotubes on the graphene foam material prepared in step a, preparing a carbon nanotube-graphene foam composite material for use;

[0051] Step c, surface-treating the carbon nanotube-graphene foam composite material prepared in step b, and stand-by after treatment;

[0052] Step d, configuring the vanadium dioxide nanosheet reaction solution for use;

[0053] Step e, place the carbon nanotube-graphene foam composite material prepared in step c completely in the vanadium dioxide nanosheet reaction solution configured in step d, control the reaction temperature at 180°C, and the reaction time for 3h, take out the product after the reaction, and use Rinse four times with deionized water and alcohol, and dry in a vacuum oven at 120°C for 6 hours. Finally, the product ...

specific Embodiment approach 2

[0070] A kind of sodium ion battery composite negative electrode material prepared according to the preparation method of a kind of sodium ion battery composite negative electrode material described in specific embodiment 1, the capacity of the described a kind of sodium ion battery composite negative electrode material≦650mAhg -1 .

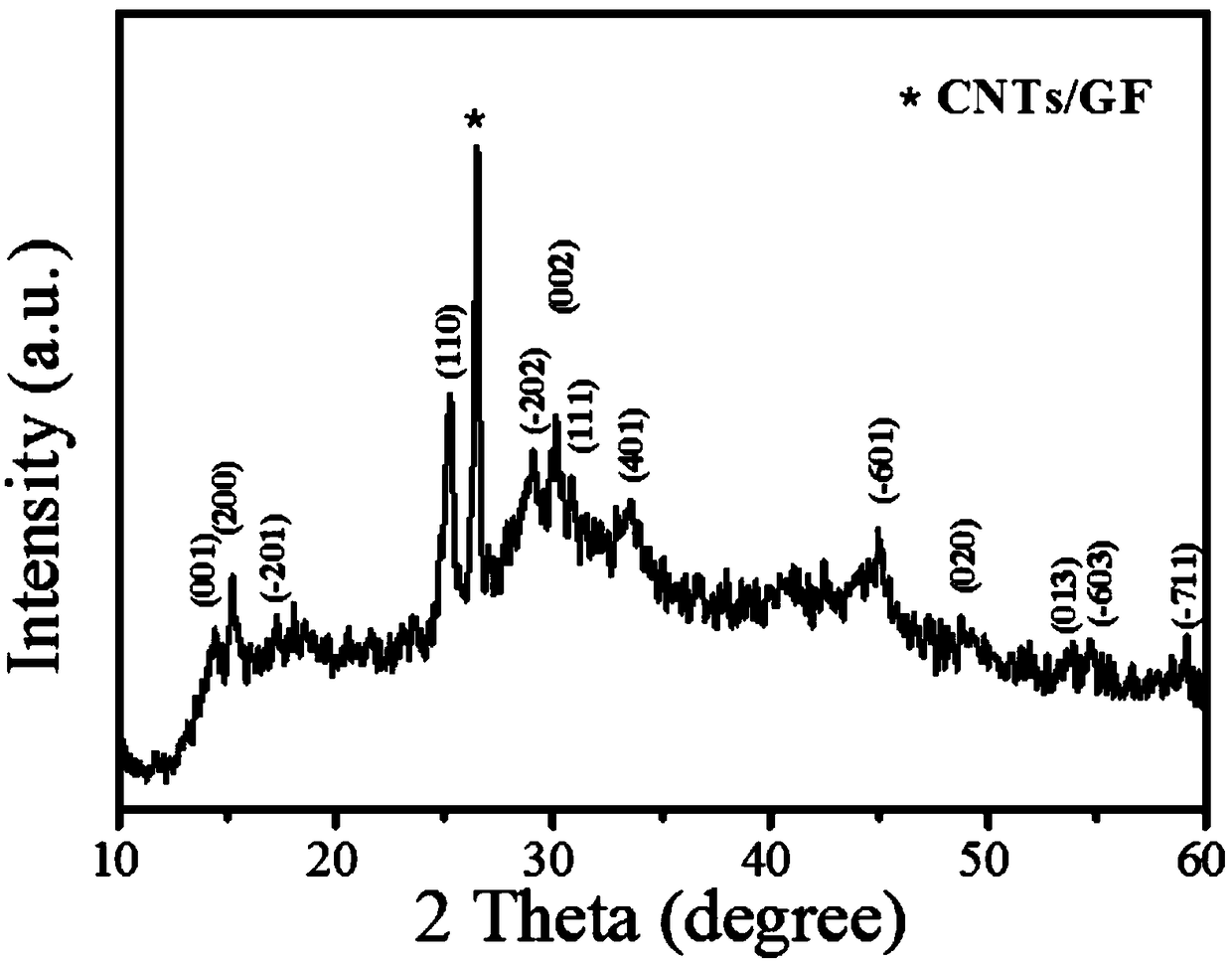

[0071] A composite negative electrode material for a sodium ion battery prepared by the method for preparing a composite negative electrode material for a sodium ion battery described in this embodiment is subjected to an X-ray diffraction test as follows: figure 1 As shown, it can be seen from the X-ray diffraction spectrum that there is a strong diffraction peak at about 26 °, which is the diffraction peak of graphene (JCPDS-NO.75-1621), corresponding to the (002) crystal plane of 2H phase graphene , and all other diffraction peaks can be consistent with the monoclinic phase VO2(B) (JCPDS-NO.31-1438) in the PDF card, without other miscellaneous...

specific Embodiment approach 3

[0075] A preparation method of a composite negative electrode material for a sodium ion battery, comprising the steps of:

[0076] Step a, prepare graphene foam material, stand-by;

[0077] Step b, growing carbon nanotubes on the graphene foam material prepared in step a, preparing a carbon nanotube-graphene foam composite material for use;

[0078] Step c, surface-treating the carbon nanotube-graphene foam composite material prepared in step b, and stand-by after treatment;

[0079] Step d, configuring the vanadium dioxide nanosheet reaction solution for use;

[0080] In step e, the carbon nanotube-graphene foam composite material prepared in step c is completely placed in the vanadium dioxide nanosheet reaction liquid prepared in step d, the reaction temperature is controlled at 175-185°C, the reaction time is 3-3.5h, and the reaction Finally, the product was taken out, rinsed with deionized water and alcohol for 3 to 5 times, and dried in a vacuum oven at 120 to 130°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com