Porous base material, porous electrode, carbon fiber paper, method for manufacturing carbon fiber paper, and method for manufacturing porous base material

A technology of porous substrate and carbon fiber paper, which is applied in the fields of porous substrate, porous electrode, carbon fiber paper, carbon fiber paper, and porous substrate manufacturing. It can solve problems such as electrolyte membrane damage and electrolyte diffusion hindrance, and achieve mechanical High strength, high drainage, high gas permeability and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

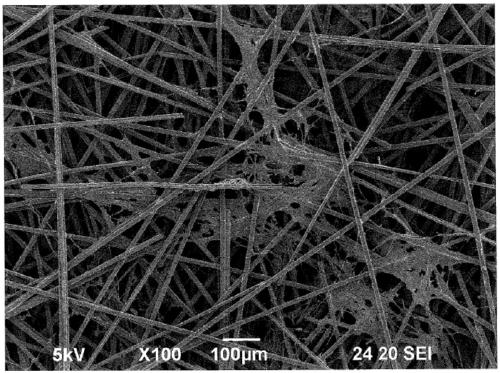

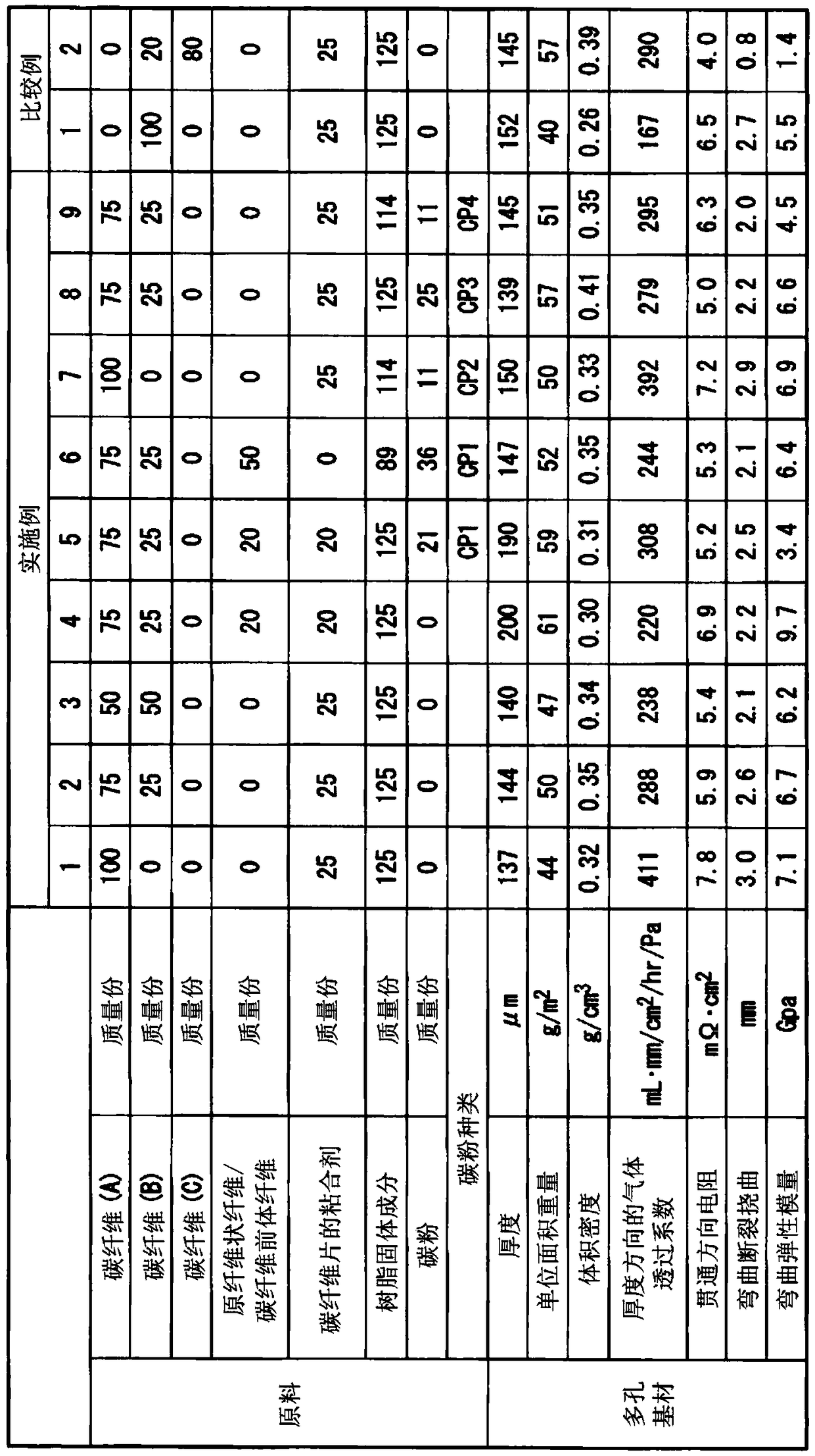

[0330] Prepare PAN-based carbon fiber (A) (manufactured by Mitsubishi Chemical Corporation, average fiber diameter: 13 μm) cut to an average fiber length of 6 mm, polyvinyl alcohol (PVA) fiber (manufactured by Kuraray Co., Ltd., trade name: VPB105-1, average fiber length 3mm).

[0331] Put carbon fiber (A) and PVA fiber in the ratio of 4:1 into the slurry tank of the wet short-wire continuous papermaking device, further add water to disperse the fiber evenly, and send out the wet cake (ウェブ) after sufficient dispersion, and send it to the short Stencil, after drying with a drier, obtain a width of 1000mm and a weight per unit area of 40g / m 2 carbon fiber sheets in roll form.

[0332] Next, the obtained carbon fiber sheet was immersed in a methanol solution of a phenolic resin (manufactured by DIC Corporation, trade name: Phenolite J-325) to obtain a phenolic resin solid adhered to 125 parts by mass of the carbon fiber sheet (100 parts by mass of the carbon fiber (A)). Compo...

Embodiment 2

[0337] As the carbon fibers, 75 parts by mass of PAN-based carbon fibers (A) (manufactured by Mitsubishi Chemical Corporation, average fiber diameter: 13 μm) cut into an average fiber length of 6 mm and PAN-based carbon fibers (B) cut into an average fiber length of 6 mm (Mitsubishi Chemical Co., Ltd. Co., Ltd. product, brand name: TR50S, average fiber diameter: 7 μm) 25 mass parts, it carried out similarly to Example 1, and obtained the porous base material which has the physical property shown in Table 1.

Embodiment 3

[0339] As carbon fibers, 50 parts by mass of PAN-based carbon fibers (A) (manufactured by Mitsubishi Chemical Corporation, average fiber diameter: 13 μm) cut to an average fiber length of 6 mm and PAN-based carbon fibers (B) cut to an average fiber length of 6 mm (Mitsubishi Chemical Corporation) were used. Co., Ltd. product, brand name: TR50S, average fiber diameter: 7 μm) 50 mass parts, it carried out similarly to Example 1, and obtained the porous base material which has the physical property shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com