Temperature-resistant probiotic chocolate product and preparation method thereof

A technology for warming probiotics and chocolate, applied in the field of probiotic chocolate products and their preparation, can solve the problems of incomparability, etc., and achieve the effects of fine taste, improved stability, and rich market product types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

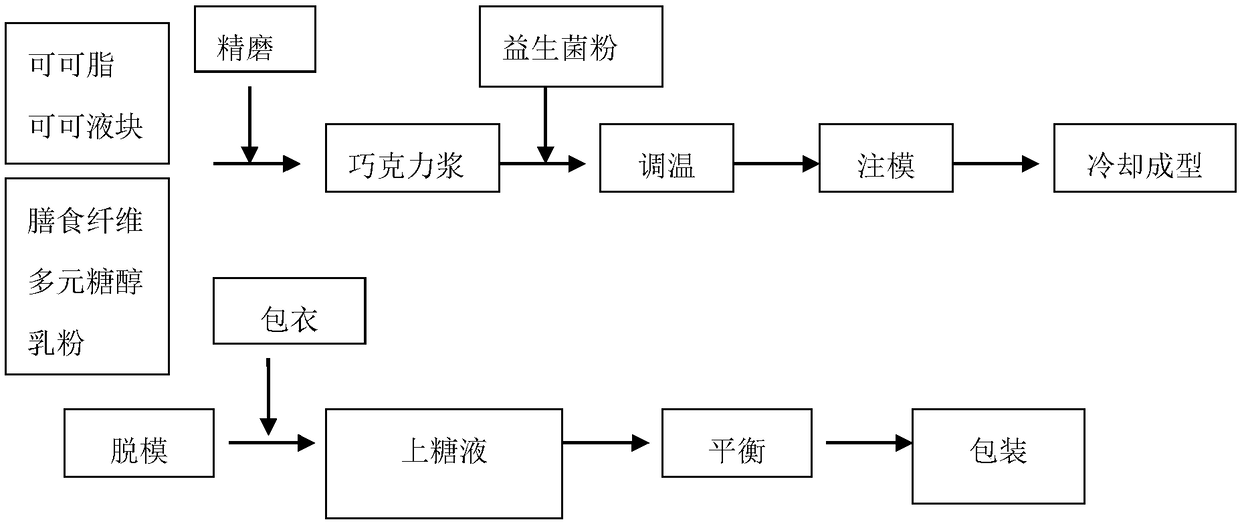

Method used

Image

Examples

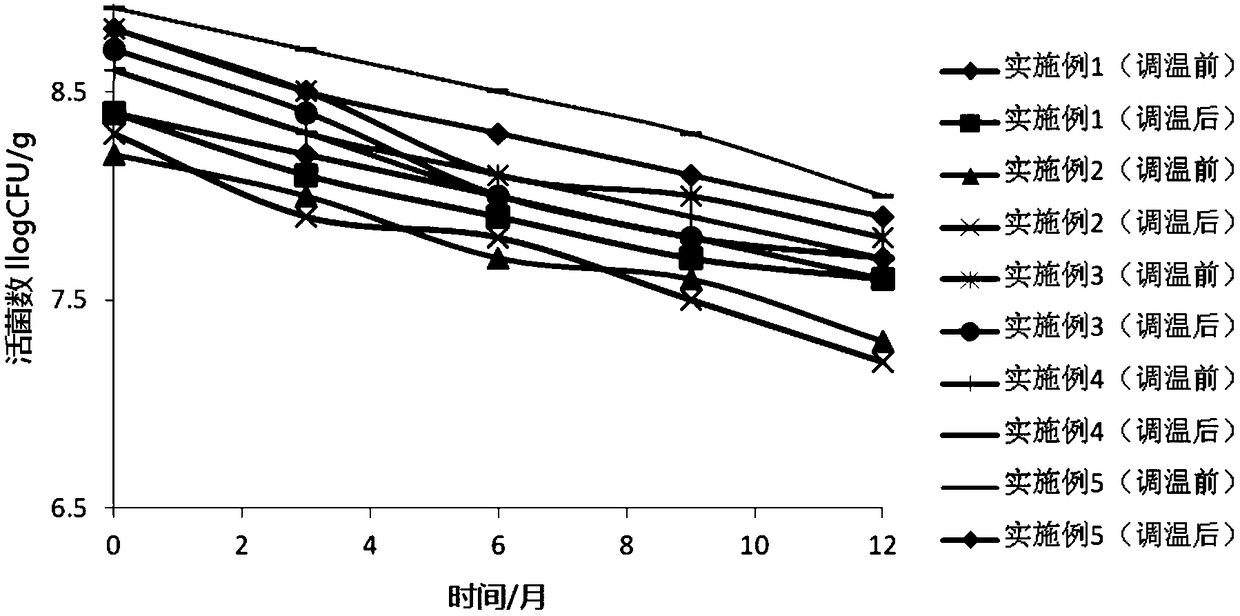

Embodiment 1

[0069] Raw materials include the following parts by weight:

[0070] 30 parts of cocoa butter, 22 parts of white sugar, 15 parts of cocoa butter, 12 parts of whole milk powder, 6 parts of skimmed milk powder, 5 parts of sorbitol, 5 parts of inulin, 3 parts of fructooligosaccharides, 0.3 parts of phospholipids, 1.7 parts of Lactobacillus acidum, 1 part of pre-coating solution, 10 parts of pre-coating powder, and 0.03 parts of shellac.

[0071] The preparation method of the present invention is as follows:

[0072] 1) Put the cocoa butter and cocoa mass into the dissolving tank respectively, melt at 40°C for 2 hours, then transfer to the fine grinding tank, add auxiliary materials, finely grind, add part of the emulsifier, and continue stirring for 3 minutes to obtain chocolate slurry; then, at 35°C, finely grind for 22 hours, and the finely milled particle size is ≤25 μm; add the remaining emulsifier 0.5 hours before finely milling; then transfer the finely milled chocolate sl...

Embodiment 2

[0085] Raw materials include the following parts by weight:

[0086]30 parts of cocoa butter, 22 parts of white sugar, 15 parts of cocoa butter, 12 parts of whole milk powder, 6 parts of skimmed milk powder, 5 parts of sorbitol, 5 parts of inulin, 3 parts of fructooligosaccharides, 0.3 parts of phospholipids, 1.7 parts of Lactobacillus acidum, 1 part of pre-coating solution, 10 parts of pre-coating powder, and 0.03 parts of shellac.

[0087] The preparation method of the present invention is as follows:

[0088] 1) Put the cocoa butter and cocoa mass into the dissolving tank respectively, melt at 60°C for 3 hours, then transfer to the fine grinding tank, add auxiliary materials, finely grind, add part of the emulsifier, and continue stirring for 5 minutes to obtain chocolate slurry; then, at 44°C, finely grind for 16 hours, and the finely milled particle size is ≤25 μm; add the remaining emulsifier 1 hour before finely milling; then transfer the finely milled chocolate slurry...

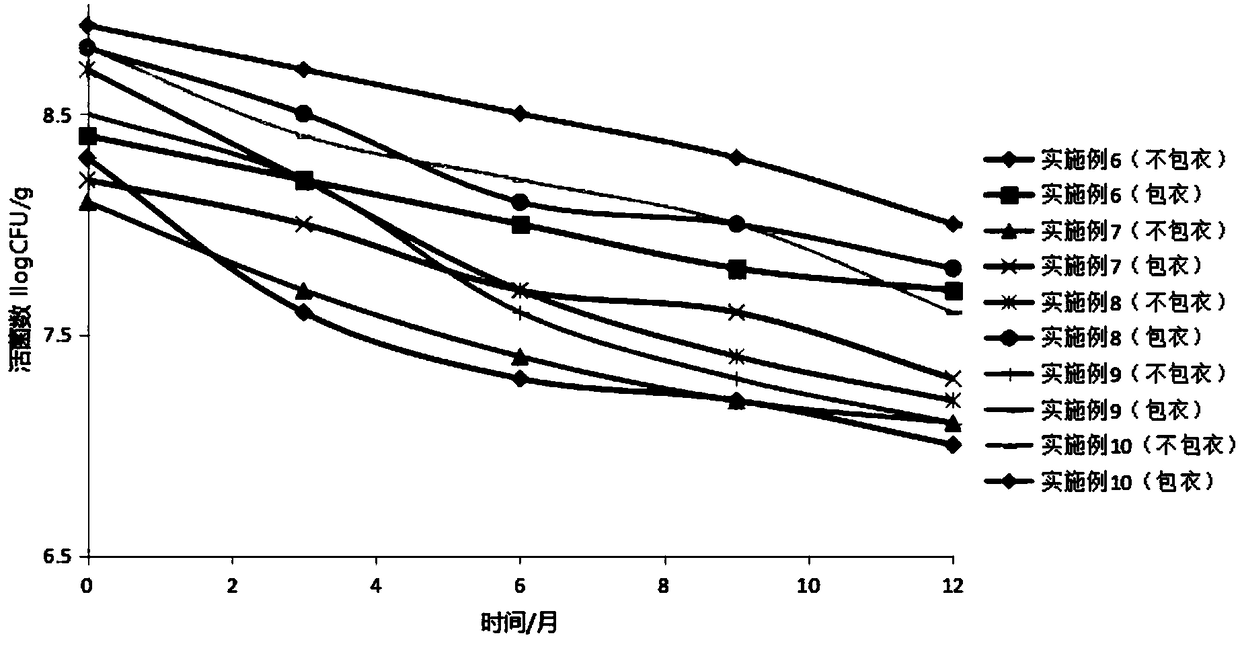

Embodiment 3

[0101] 20 parts of cocoa butter, 20 parts of white sugar, 10 parts of cocoa mass, 10 parts of whole milk powder, 5 parts of isomalt, 5 parts of resistant dextrin, 0.3 parts of polyglycerol ricinoleate, 0.2 parts of phospholipids, 1.4 parts of Lactobacillus rhamnosus, 1 part of pre-coating liquid, 15 parts of pre-coating powder, 0.03 parts of shellac.

[0102] The preparation method of the present invention is as follows:

[0103] 1) Put the cocoa butter and cocoa mass into the dissolving tank respectively, melt at 40°C for 2 hours, then transfer to the fine grinding tank, add auxiliary materials, finely grind, add part of the emulsifier, and continue stirring for 3 minutes to obtain chocolate slurry; then, at 35°C, finely grind for 22 hours, and the finely milled particle size is ≤25 μm; add the remaining emulsifier 0.5 hours before finely milling; then transfer the finely milled chocolate slurry to a 30°C insulation cylinder and keep it warm for 24 Hour;

[0104] 2) Take th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com