Stevia rebaudiana Bertoni stalk and alfalfa mixed and wrapped silage feed and preparation method thereof

A technology of silage and stevia, applied in animal feed, animal feed, application, etc., can solve the problems of low soluble sugar content of alfalfa, difficulty in conventional silage of alfalfa, insufficient lactic acid production, etc., and achieve soft texture, high quality, high protein content high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

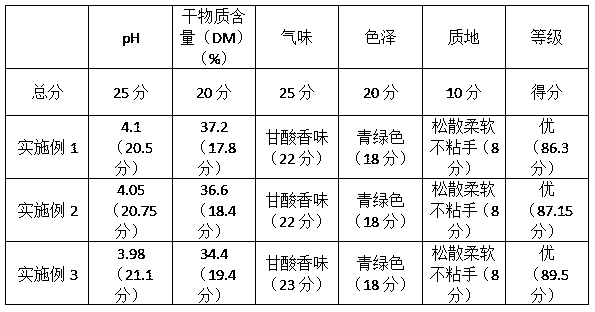

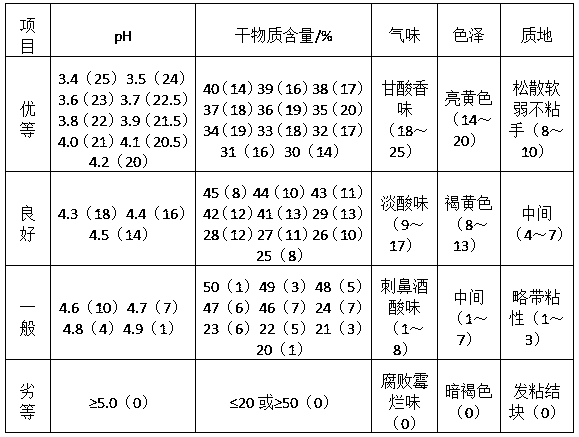

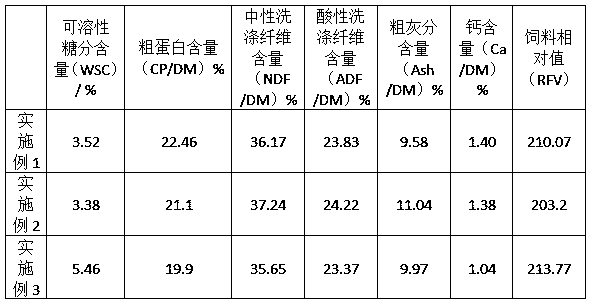

Examples

Embodiment 1

[0029] In this embodiment, stevia stalks and alfalfa mixed wrapped silage are made by the following steps:

[0030] (1) Raw material selection and harvesting: Recycling the waste stalks of stevia rebaudiana after utilization, and harvesting alfalfa at the budding stage (the flowering rate is about 3%);

[0031] (2) Kneading, mixing and chopping: Mix 5% stevia stalks and 95% alfalfa evenly by weight, knead and chop into 2-5cm long fragments through a 9FR-15 forage crushing and kneading machine;

[0032] (3) Bundling: The above-mentioned mixed and chopped silage raw materials are compacted and wrapped with high-density 9YQ-1.0 round bale balers to obtain a bale with a size of Φ100cm*85cm and a baling density of 650- 700kg / m 3 , the number of winding layers is 4 layers;

[0033] (4) Wrapping: the mixed silage raw materials of stevia rebaudiana stalks and alfalfa are compacted and bundled with polyethylene stretch film to wrap and seal the bale through the 9YCG-1.0 hanging round...

Embodiment 2

[0036] In this embodiment, stevia stalks and alfalfa mixed wrapped silage are made by the following steps:

[0037] (1) Raw material selection and harvesting: recycle the waste stems of stevia rebaudiana, and harvest the alfalfa when it is approaching the initial flowering period (the flowering rate is about 5%);

[0038] (2) Kneading, mixing and chopping: Mix 8% stevia stalks and 92% alfalfa evenly by weight, and knead and chop them into 2-5cm long fragments through a 9FR-15 forage crushing and kneading machine;

[0039] (3) Bundling: The above-mentioned mixed and chopped silage raw materials are compacted and wrapped with high-density 9YQ-1.0 round bale balers to obtain a bale with a size of Φ100cm*85cm and a bale density of 700- 800 kg / m 3 , the number of winding layers is 4 layers;

[0040] (4) Wrapping: the mixed silage raw materials of stevia rebaudiana stalks and alfalfa are compacted and bundled with polyethylene stretch film to wrap and seal the bale through the 9YC...

Embodiment 3

[0043] The stevia stalk of present embodiment and alfalfa mixed wrapping silage are made by following steps:

[0044] (1) Raw material selection and harvesting: Recycling the discarded stevia stalks after utilization, and harvesting alfalfa at the initial flowering stage (about 7% flowering rate);

[0045] (2) Kneading, mixing and chopping: Mix 10% stevia stalks and 90% alfalfa evenly by weight, and knead and chop them into 2-5cm long fragments through a 9FR-15 forage crushing and kneading machine;

[0046] (3) Bundling: The above-mentioned mixed and chopped silage raw materials are compacted and wrapped with high-density 9YQ-1.0 round bale baler to obtain a bale with a size of Φ100cm*85cm and a bale density of 750- 850 kg / m 3, the number of winding layers is 4 layers;

[0047] (4) Wrapping: the mixed silage raw materials of stevia rebaudiana stalks and alfalfa are compacted and bundled with polyethylene stretch film to wrap and seal the bale through the 9YCG-1.0 hanging rou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com