A coal-to-methanol synthesis gas purification sulfur recovery process

A technology for gas purification of sulfur and coal to methanol, applied in the chemical industry, sustainable manufacturing/processing, inorganic chemistry, etc., to achieve the effect of avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

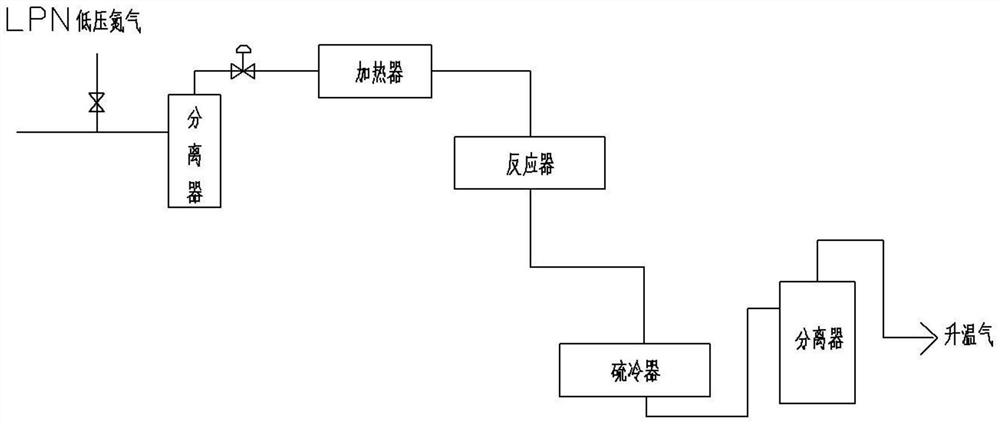

Embodiment 1

[0075] One kind of coal, methanol synthesis purge gas sulfur recovery process, comprising heating the catalyst after synthesis of elemental sulfur, a sulfur scavenging outage means, includes the following steps:

[0076] (1) heating the catalyst:

[0077] For sulfur recovery and nitrogen replacement heating system, when replacing the end ≤0.05% sulfur recovery catalyst warm up before the combustible gas reaches the gas analyzer volume content indicators; substituted eligibility criteria for the system CO, H 2 H 2 S, CH 3 The total volume of the OH content ≤0.05%;

[0078] When at / h heating rate of 30 ~ 40 ℃ sulfur recovery apparatus for heating a catalyst bed heater with nitrogen, the inlet temperature of the catalyst bed was raised to 80 ± 10 ℃, 2 hours to remove physically adsorbed water temperature, while the catalyst of each flare interpass temperature; at / h heating rate of 30 ~ 40 ℃ control the catalyst bed inlet temperature was raised to 120 ± 10 ℃, constant for 2 hours ...

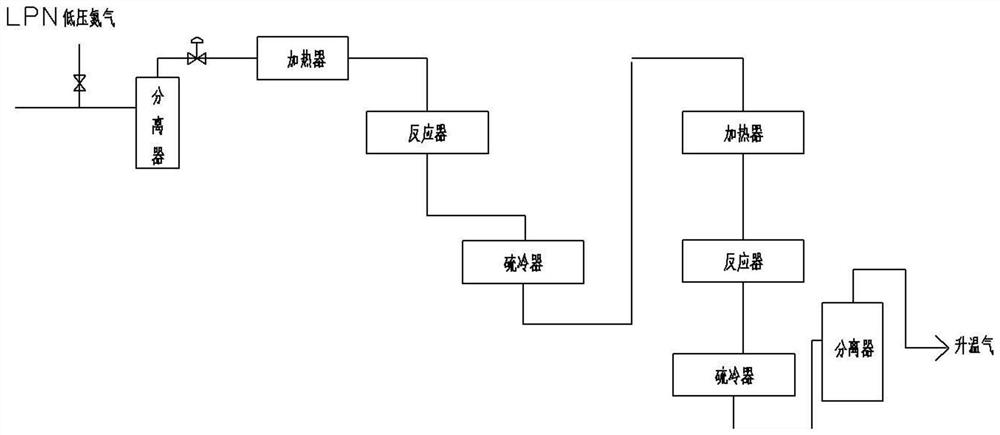

Embodiment 2

[0101] A coal-forming methanol synthesis gas purification sulfur recovery process, including the temperature rise of the catalyst, the synthesis of single-tape sulfur, after the device is off, including the following steps:

[0102] (1) The temperature rise of the catalyst:

[0103] The sulfur recovery and nitrogen warming system are replaced, and when the sulfur recovery catalyst begins the temperature analysis index to reach the gas volume content of ≤ 0.05%, the replacement is completed.

[0104] The sulfur recovery apparatus catalyst bed is raised by a temperature rise rate of 30 to 40 ° C / h by a nitrogen heater, and when the catalyst bed inlet temperature rises to 80 ± 10 ° C, the constant temperature is 2 hours to remove physical adsorbent water, and the graft catalyst is pulled. Layer temperature; controlling the temperature of the catalyst bed at a temperature rise rate of 30 to 40 ° C / h rises to 120 ± 10 ° C, and the temperature of 2 hours at the temperature is 2 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com