A kind of cementitious material using coal gangue as raw material and preparation method thereof

A technology of cementitious materials and coal gangue, which is applied in the direction of cement production, etc., can solve the problems of occupying land resources, weathered coal gangue not being effectively used, and polluting the atmosphere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

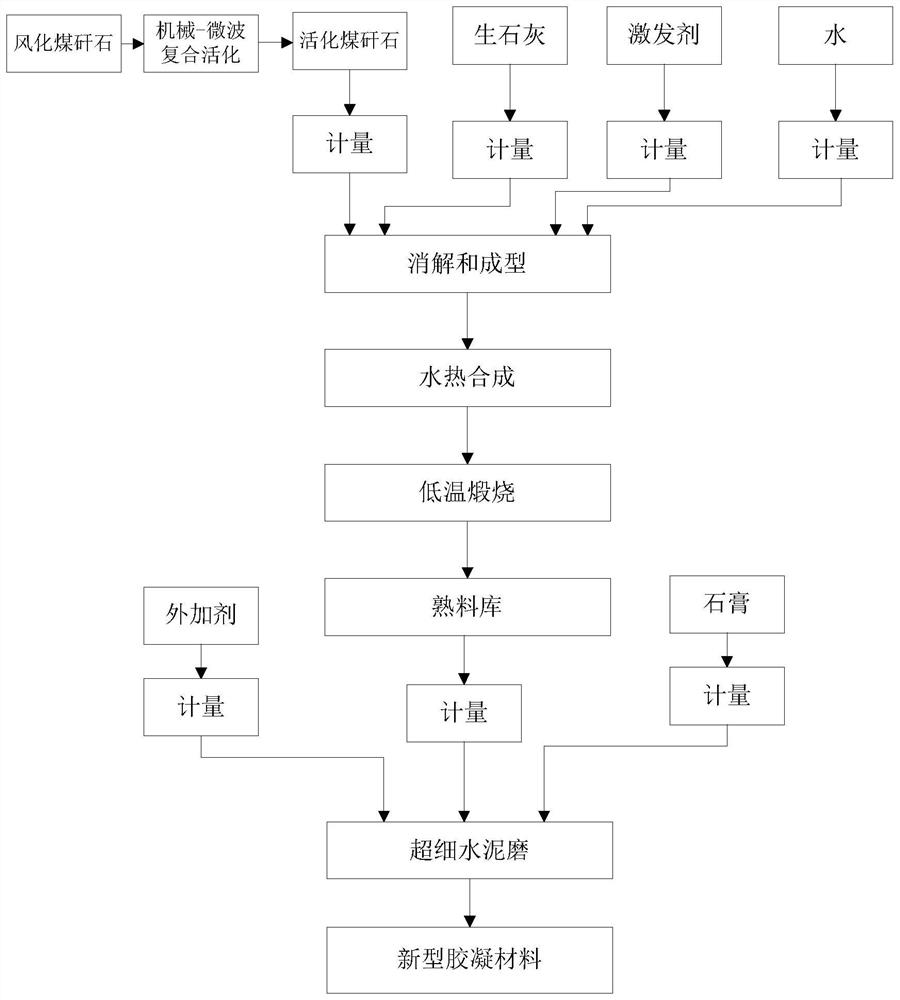

Method used

Image

Examples

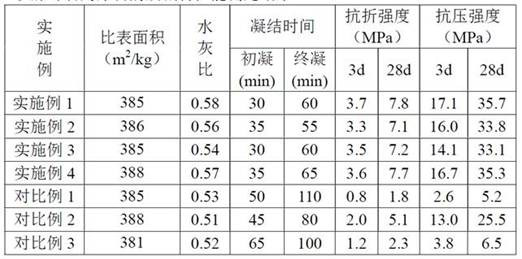

Embodiment 1

[0021] A cementitious material (by mass parts) using coal gangue as raw material contains the following components:

[0022] 75 parts of coal gangue

[0023] Quicklime 25 parts

[0024] Sodium hydroxide 1.3 parts

[0025] Digestion water 50 parts

[0026] Forming water 40 parts

[0027] Grind the weathered coal gangue to 4.5% of the 80 μm sieve, and then microwave activation for 5 minutes to form activated coal gangue powder. Mix 75 parts of activated coal gangue powder, 25 parts of quicklime, 1.3 parts of sodium hydroxide, and 50 parts of water. Digest at room temperature for 6h. Add 40 parts of water to the digested raw materials to form pellets, put the pelleted regular samples into a steam curing box at 97°C for 12 hours, and then put the steamed materials into a kiln for calcination at 800°C for 1 hour, and then cool them quickly. Take 92 parts of clinker, mix with 8 parts of natural gypsum and 0.5 parts of polycarboxylate superplasticizer, mix evenly, and grind it w...

Embodiment 2

[0029] A cementitious material (by mass parts) using coal gangue as raw material contains the following components:

[0030] Coal gangue 70 parts

[0031] Quicklime 30 parts

[0033] Digestion water 50 parts

[0034] Forming water 40 parts

[0035] Grind the weathered coal gangue to 4.0% of the 80 μm sieve, and then microwave activation for 4 minutes to form activated coal gangue powder. Mix 70 parts of activated coal gangue powder, 30 parts of quicklime, 2 parts of sodium sulfate, and 50 parts of water evenly. Digest at room temperature for 6h. Add 40 parts of water to the digested raw materials to form pellets, put the pelleted regular samples into a steam curing box at 99°C for 12 hours, and then put the steamed materials into a kiln for calcination at 750°C for 1 hour, and then cool them quickly. Take 94 parts of clinker, mix with 6 parts of natural gypsum and 1.0 part of calcium lignosulfonate, mix evenly, and grind it with ultra-fine ...

Embodiment 3

[0037] A cementitious material (by mass parts) using coal gangue as raw material contains the following components:

[0038] 65 parts of coal gangue

[0039] Quicklime 35 parts

[0040] Sodium hydroxide 1.94 parts

[0041] Digestion water 50 parts

[0042] Forming water 40 parts

[0043] Grind the weathered gangue to 4.4% of the 80 μm sieve, and then activate it by microwave for 8 minutes to form activated gangue powder. Mix 65 parts of activated coal gangue powder, 35 parts of quicklime, 1.94 parts of sodium hydroxide, and 50 parts of water. Digest at room temperature for 6h. Add 40 parts of water to the digested raw materials to form pellets, put the pelleted regular samples into a steam curing box at 97°C for 12 hours, and then put the steamed materials into a kiln for calcination at 850°C for 0.5 hours, and then cool them down quickly. Take 93 parts of clinker, mix with 7 parts of natural gypsum and 1.5 parts of nano-based superplasticizer, mix them evenly, and grind ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com