Process for preparing sheet trititanium pentoxide by TiC reduction

A technology for titanium pentoxide and titanium dioxide is applied in the field of preparation of flake titanium pentoxide and titanium pentoxide by reducing TiC, and can solve the problems of extremely high production equipment requirements, difficult to guarantee safety factor, harsh reaction conditions and the like. , to achieve the effect of reducing production cost, shortening pre-melting time, and low outgassing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

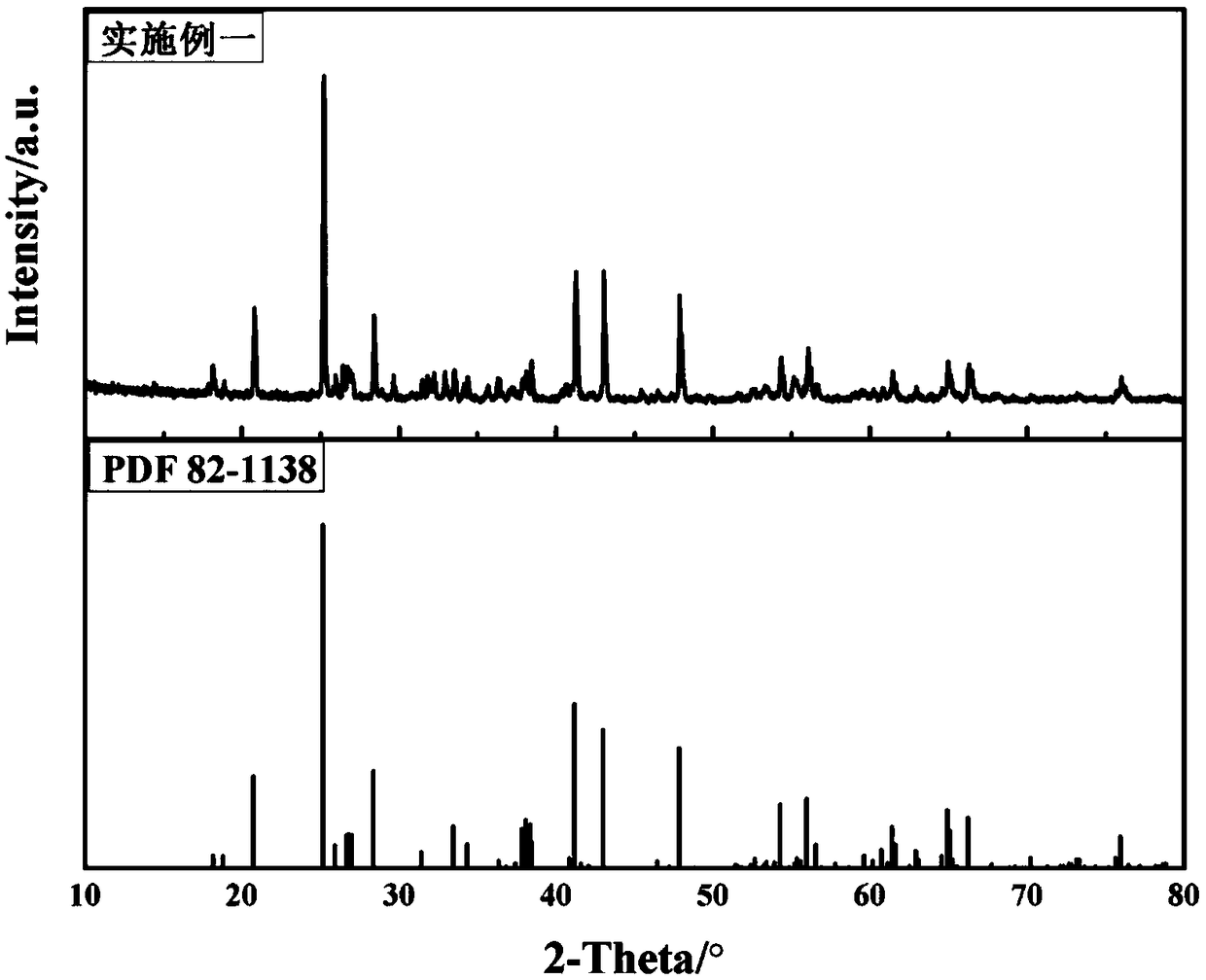

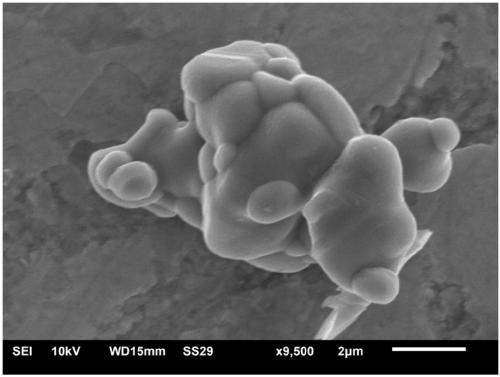

Embodiment 1

[0036] Step 1: According to the mass ratio of titanium carbide: titanium dioxide = 1:8.5, weigh the raw materials titanium carbide and titanium dioxide respectively, add water and ball mill for 24 hours, the ball milling speed is 150r / min, the mass ratio of water and mixed powder is 2.5:1; take out the material after ball milling Dry in a drying oven at 60°C, take out the mixture after drying is complete, pass through a 100-mesh sieve after mechanical grinding; adopt dry pressing, the pressure is 1.5MPa, and the time is 60s to obtain the mixture tablet;

[0037] Step 2: Put the mixed material tablet obtained in step 1 into a crucible and place it in a muffle furnace, and pass argon gas into the furnace cavity for 20 minutes to exhaust the air in the furnace cavity;

[0038] Step 3: Sintering in stages, and continuously feed argon gas throughout the sintering process, the steps are as follows:

[0039] A. Room temperature ~ 1100°C, heating rate 1°C / min;

[0040] B.1100℃, keep ...

Embodiment 2

[0050]Step 1: According to the mass ratio of titanium carbide: titanium dioxide = 1:10, weigh the raw materials titanium carbide and titanium dioxide respectively, add water and ball mill for 28 hours, the ball milling speed is 250r / min, the mass ratio of water and mixed powder is 3:1; take out the material after ball milling Dry in an oven at 80°C, take out the mixture after drying is complete, and pass through a 100-mesh sieve after mechanical grinding; use dry pressing to form, the pressure is 3MPa, and the time is 15s to obtain the mixture tablet;

[0051] Step 2: Put the mixed material tablet obtained in step 1 into a crucible and place it in a muffle furnace, and pass argon gas into the furnace cavity for 20 minutes to exhaust the air in the furnace cavity;

[0052] Step 3: Sintering in stages, and continuously feed argon gas throughout the sintering process, the steps are as follows:

[0053] A. Room temperature ~ 1100°C, heating rate 2°C / min;

[0054] B.1100℃, keep wa...

Embodiment 3

[0063] Step 1: According to the mass ratio of titanium carbide: titanium dioxide = 1:9.5, weigh the raw materials titanium carbide and titanium dioxide respectively, add water and ball mill for 28 hours, the ball milling speed is 200r / min, the mass ratio of water and mixed powder is 5:1; take out the material after ball milling Dry in a drying oven at 60°C, take out the mixed material after drying, and pass through a 100-mesh sieve after mechanical grinding; use dry pressing, the pressure is 3MPa, the time is 15s, followed by cold isostatic pressing, the parameter is 250MPa, the time is 15s Be 400s, obtain mixed material compression tablet;

[0064] Step 2: Put the mixed material tablet obtained in step 1 into a crucible and place it in a muffle furnace, and pass nitrogen into the furnace cavity for 20 minutes to exhaust the air in the furnace cavity;

[0065] Step 3: Sintering in stages, and nitrogen gas is continuously fed throughout the sintering process, the steps are as f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com