Preparation of vitrified Ta2O5-TiO2 composite metal oxide vapor deposition material

A ta2o5-tio2, composite oxide technology, applied in metal material coating technology, vacuum evaporation coating, sputtering coating, etc., can solve the problems of prolonging the coating cycle, cumbersome operation, increasing production costs, etc., and achieve growth saving Low cost, good repeatability and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

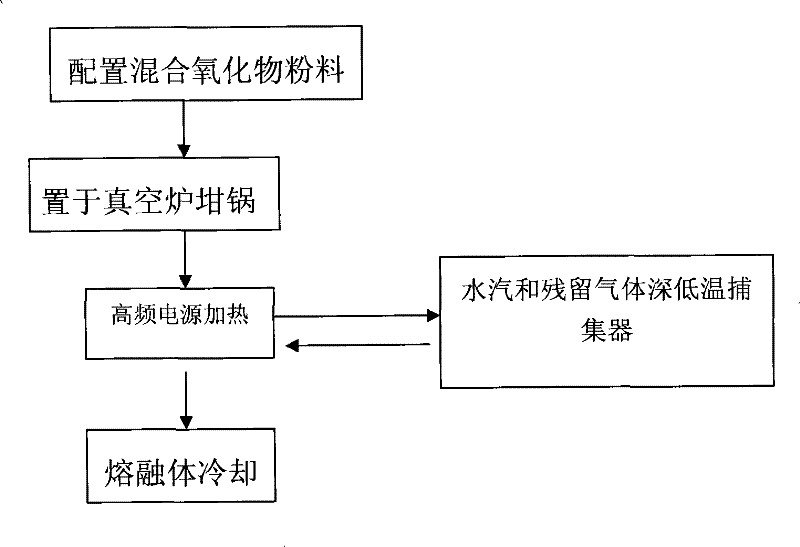

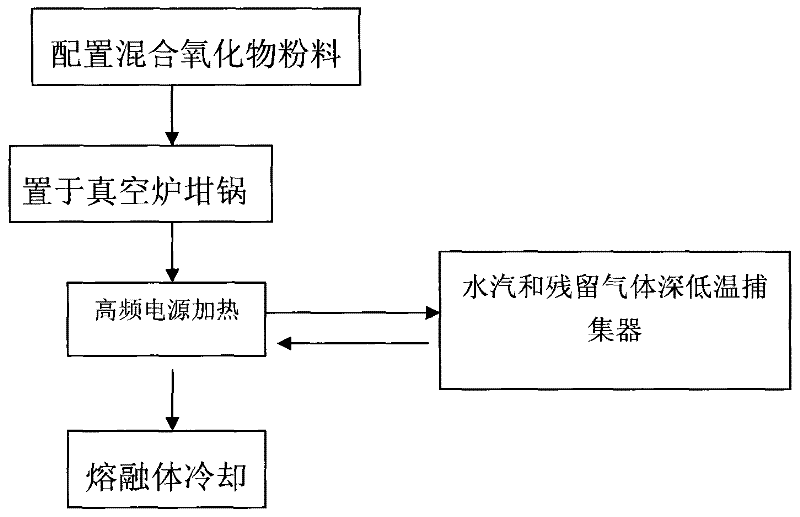

[0020] Will prepare Ta according to the weight ratio 2 o 5 (70%-90%) and TiO 2 (10%-30%) mixed oxide powder is placed in a vacuum furnace (crucible), at ≤1×10 -2 The mixed oxide powder is heated to 1800°C by a high-frequency source under Pa vacuum, melted in a vacuum furnace (crucible) and supplemented with a deep cryogenic trap trap of ≤ -120°C to capture the moisture and moisture in the powder. Other residual gas, while slowly cooling through the crucible (falling speed 5-10mm / h), finally get pre-melted crystallized Ta 2 o 5 -TiO 2 Composite oxide products.

[0021] Since the composite oxides are refractory high-temperature materials, they cannot be fused to grow crystals in a crucible made of high-melting-point metal materials. Therefore, the present invention directly uses the Ta 2 o 5 and TiO 2 The mixed oxide raw material itself is used as the crucible material, and the inside of the crucible is fully melted with a high-frequency power source in a vacuum furnace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com