Process for producing vitrification SiO2-Al2O3 mix oxide deposition material

A mixed oxide, sio2-al2o3 technology, applied in the direction of vacuum evaporation coating, metal material coating process, sputtering coating, etc., can solve the problems of increasing production cost, cumbersome operation, and prolonging the coating cycle, so as to save production The effect of low cost, good repeatability and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

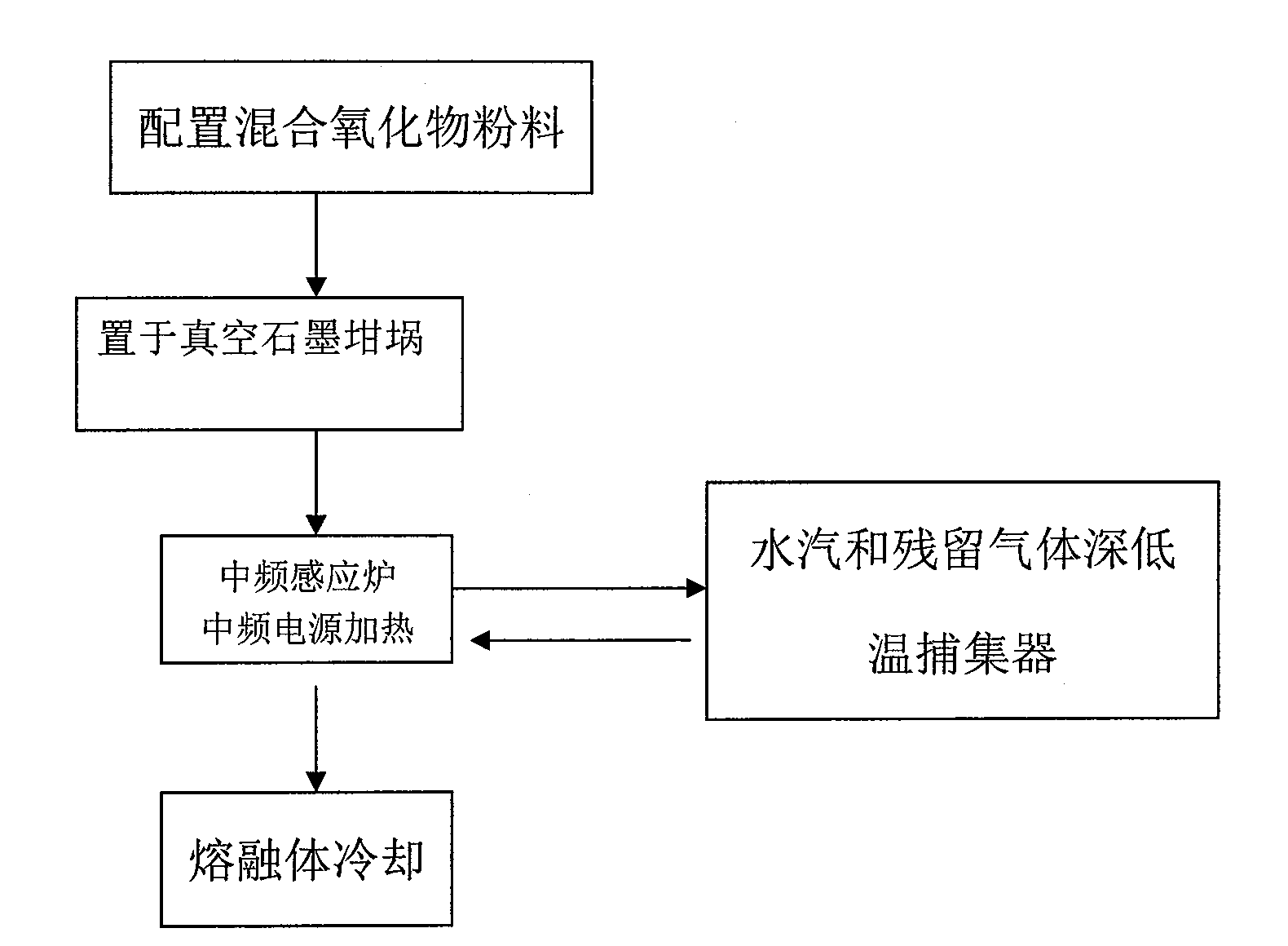

[0018] Embodiment: SiO will be prepared by weight ratio 2 (50%-90%) and Al 2 o 3 (10%-50%) The mixed powder is put into the graphite crucible of the vacuum intermediate frequency induction furnace, and the vacuum pressure is less than or equal to 1×10 -2 Under Pa, the graphite crucible is heated by induction in the medium frequency induction furnace. Due to heat radiation and conduction, the mixed oxide powder is heated to 1650-1750°C and melted. The temperature of the melt gradually decreases due to the slow settlement of the graphite crucible and away from the heating zone. Reduce and control the sedimentation speed (this speed is a common technique) to form a crystalline oxide pre-melt. In order to ensure the high purity of the pre-melt, during the whole preparation process, the residual gas and water vapor in the intermediate frequency induction furnace are absorbed by the cold trap trap (device) with a temperature of minus 120 degrees Celsius, reducing the impact on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com