A kind of premelted high refractive index optical coating material and its preparation method and application

An optical coating and high refractive index technology, applied in chemical instruments and methods, inorganic chemistry, sputtering coating, etc., can solve problems such as poor consistency of production batches and unstable performance of optical films, and achieve dense film layers and high performance Consistent, improved low-index effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

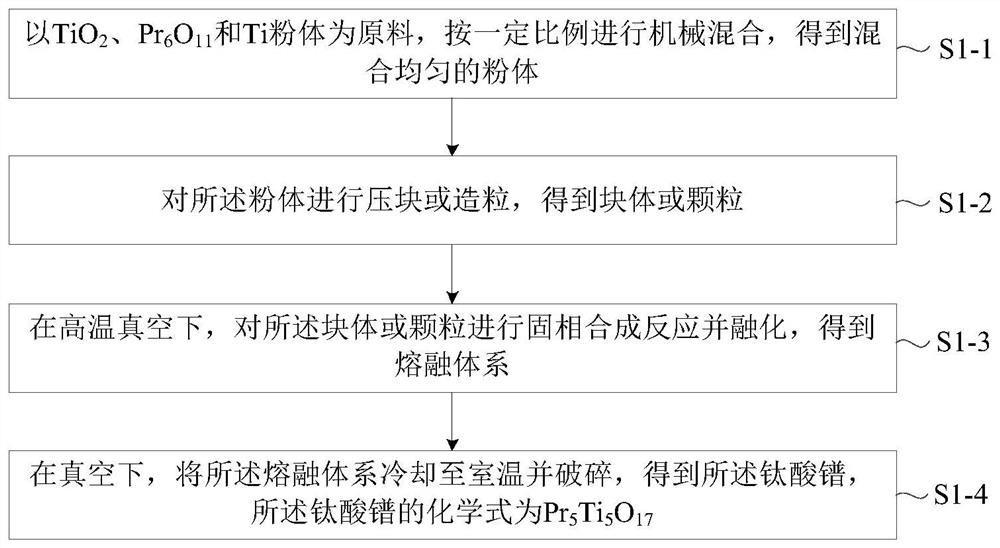

[0037] Embodiments of the present invention provide a pre-melted high refractive index optical coating material and a preparation method thereof. It mainly includes the following steps: using TiO 2 , Pr 6 O 11 and Ti powder as raw materials, mechanically mixed uniformly according to a certain ratio and then briqueted, then solid-phase synthesis and melting under high temperature vacuum, crystallized under vacuum state and cooled to room temperature to generate a new compound Pr 5 Ti 5 O 17 . The compound maintains a stable chemical composition during the evaporation process, and can form a very flat evaporation surface during pre-melting, which is beneficial to the process control of the coating process. The optical film layer coated with this material has high transmittance in the near-ultraviolet to near-infrared band, the film layer is dense, firm, and chemically stable, and can be used as a high-quality high-refractive index material for optical film system design and...

Embodiment 1

[0072] According to the raw material ratio of TiO 2 26%(wt.),Pr 6 O 11 71% (wt.), Ti 2.5% (wt.) were accurately weighed, mechanically mixed for 8 hours with a stirring mixer, and the mixed powder was mixed with a hydraulic press at 400N / cm 2 Under the pressure of 2000℃, the furnace is heated at a rate of 5℃ / min, and the temperature is 2000℃ and the degree of vacuum is 2×10 -1 The solid-phase synthesis reaction was carried out under the condition of Pa for 8 h, and cooled to room temperature under vacuum. The material prepared by this method is a black molten material (its appearance is as figure 2 As shown, the density of the material tested by the drainage method is 5.4g / cm 3 .

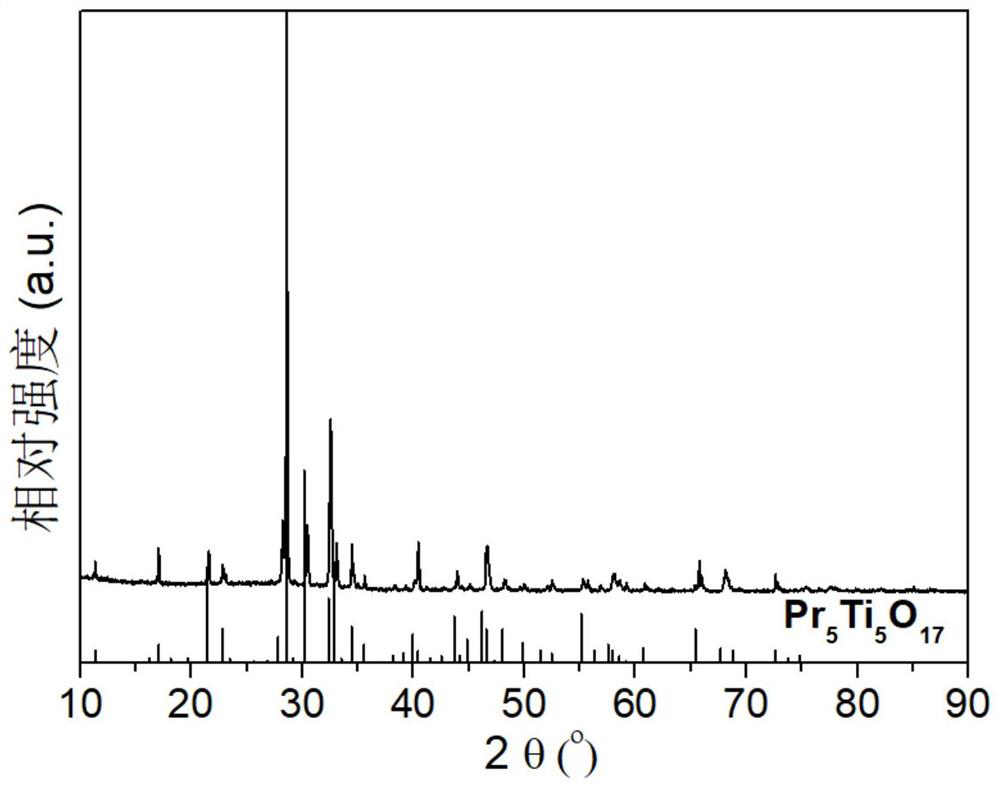

[0073] image 3 The XRD pattern of the praseodymium titanate fused particulate material prepared in Example 1 of the present invention is shown. Depend on image 3 It can be seen that the praseodymium titanate obtained by this method has a single-phase structure, and the structure is simil...

Embodiment 2

[0079] According to the raw material ratio of TiO 2 25%(wt.),Pr 6 O 11 72% (wt.), Ti 3% (wt.) were accurately weighed, mechanically mixed with a stirring mixer for 8 hours, and the mixed powder was mixed with a hydraulic press at 400N / cm 2 Under the pressure of briquetting and furnace, the furnace heating rate is 5℃ / min under vacuum state, the temperature is 1900℃, and the vacuum degree is 2×10 -1 The solid-phase synthesis reaction was carried out under the condition of Pa for 8 h, and cooled to room temperature under vacuum. The material prepared by this method is a black molten material (its appearance is as Image 6 shown), the density of the material tested by the drainage method is 5.4g / cm 3 .

[0080] When using, first fully pre-melt the material, and pre-melt the material in a water-cooled oxygen-free copper crucible. The pre-melting temperature is 2200 ° C. The pre-melting process does not splash, and the material surface is in a molten state after pre-melting. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com