Processing method of high-stability nano superlattice electrothermal material

An electrothermal material and high-stability technology, applied in the field of material processing, can solve problems that affect stability and life, are not suitable for large-scale applications, and reduce market competitiveness, so as to improve bonding strength, enhance surface reactivity and ability, the effect of improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

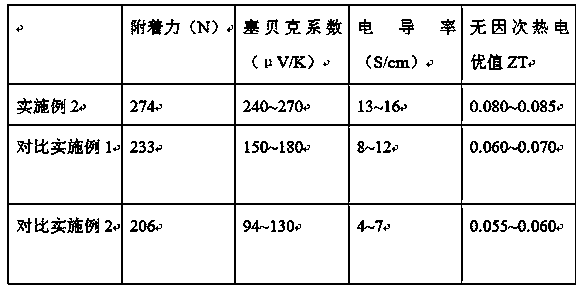

Examples

Embodiment 1

[0029] A method for processing a high-stability nano-superlattice electrothermal material, comprising the steps of:

[0030] (1) Preparation of compound additives:

[0031] a. Mix potassium sodium niobate powder and hydrochloric acid solution into a three-necked flask, and keep stirring for 6 minutes to obtain mixed solution A for later use;

[0032] b. Mix pyrrole and hydrochloric acid solution together and put them into a three-necked flask, and keep stirring for 8 minutes to obtain the mixed solution B for later use;

[0033] c. Mix ammonium peroxodisulfate and hydrochloric acid solution and put them into a three-necked flask, and keep stirring for 10 minutes to obtain mixed solution C for later use;

[0034] d. Graphene, sodium pyrophosphate, dodecyltrimethylammonium bromide, disodium edetate, and deionized water are mixed and stirred according to the weight ratio of 14:4:2:0.5:75, constantly After stirring for 1 h, the mixed solution D was obtained for subsequent use; ...

Embodiment 2

[0048] A method for processing a high-stability nano-superlattice electrothermal material, comprising the steps of:

[0049] (1) Preparation of compound additives:

[0050] a. The potassium sodium niobate powder and the hydrochloric acid solution are mixed and put into a three-neck flask, and the mixed solution A is obtained after continuous stirring for 7 minutes;

[0051] b. Pyrrole and hydrochloric acid solution were mixed together and dropped into a three-necked flask, and the mixed solution B was obtained after continuous stirring for 9 minutes;

[0052] c. Mix ammonium peroxodisulfate and hydrochloric acid solution together and put them into a three-necked flask, and keep stirring for 11 minutes to obtain mixed solution C for later use;

[0053] d. Graphene, sodium pyrophosphate, dodecyltrimethylammonium bromide, disodium edetate, and deionized water are mixed and stirred according to the weight ratio of 16:6:4:0.8:77, constantly After stirring for 1.3 hours, the mixed s...

Embodiment 3

[0067] A method for processing a high-stability nano-superlattice electrothermal material, comprising the steps of:

[0068] (1) Preparation of compound additives:

[0069] a. Mix potassium sodium niobate powder and hydrochloric acid solution into a three-necked flask, and keep stirring for 8 minutes to obtain mixed solution A for later use;

[0070] b. Mix pyrrole and hydrochloric acid solution together and put them into a three-necked flask, and keep stirring for 10 minutes to obtain the mixed solution B for later use;

[0071] c. Mix ammonium peroxodisulfate and hydrochloric acid solution together and put them into a three-necked flask, and keep stirring for 12 minutes to obtain mixed solution C for subsequent use;

[0072] d. Graphene, sodium pyrophosphate, dodecyltrimethylammonium bromide, disodium edetate, and deionized water are mixed and stirred according to the weight ratio of 18:7:5:1:80, constantly After stirring for 1.5 hours, the mixed solution D was obtained fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com