High-energy nitrine propellant and preparation method thereof

A propellant and high-energy technology, which is applied in the direction of offensive equipment, compressed gas generation, explosives, etc., can solve the problems of increased propellant burning rate pressure index, high propellant burning rate pressure index, and poor wettability of binder system, etc. , to achieve the effects of low burning rate pressure index, small visible smoke and good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The embodiment of the present invention also provides a preparation method of an azide high-energy propellant, comprising the following steps:

[0036] (1) According to the prescription provided by the above-mentioned embodiment, the raw materials are weighed;

[0037] For the specific description of the formula, please refer to the above-mentioned examples, and details are not repeated here.

[0038] (2) mixing the raw materials to obtain propellant slurry;

[0039] (3) Casting and solidifying the propellant slurry to obtain an azide high-energy propellant.

[0040] In an optional embodiment, mixing the raw materials described in step (2) includes:

[0041] The nitrates taken by weighing are mixed with N-butyl-2-nitroxyethyl ammonium nitrate to obtain a plasticizer;

[0042] According to the plasticizing ratio, the polyazide glycidyl ether taken by weighing is mixed with a certain amount of plasticizer to obtain the first glue solution; the weighed 3,3-bis(azidomethyl...

Embodiment 1

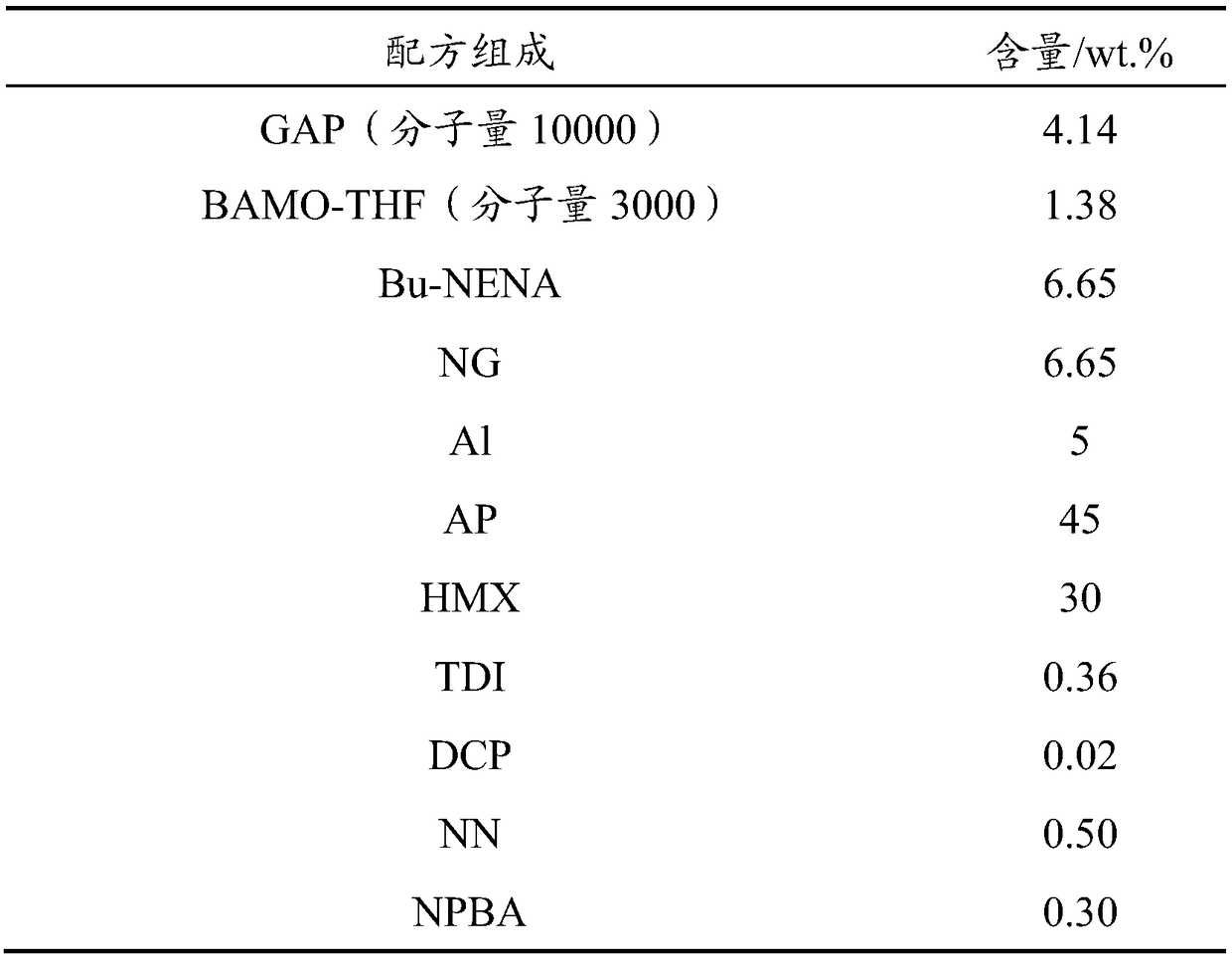

[0050] (1) The propellant formula composition (mass percentage) is shown in Table 1-1:

[0051] Table 1-1 Propellant formulation

[0052]

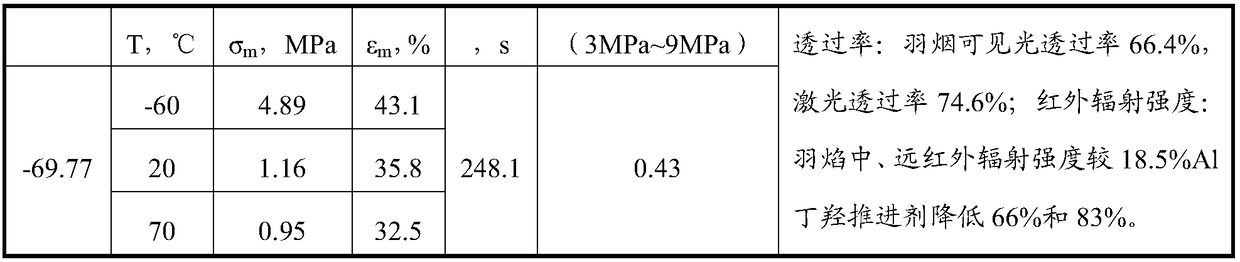

[0053] (2) The comprehensive performance of the propellant is shown in Table 2-1:

[0054] Table 2-1 Propellant Performance Parameters

[0055]

[0056]

Embodiment 2

[0058] (1) The propellant formula composition (mass percentage) is shown in Table 1-2:

[0059] Table 1-2 Propellant formulation

[0060]

[0061] (2) The overall performance of the propellant is shown in Table 2-2:

[0062] Table 2-2 Propellant Performance Parameters

[0063]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com