Sodium bromate production technology

A production process, sodium bromate technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of many raw materials and reaction media, long process flow, and fast electrode consumption, so as to improve the labor and production conditions of employees and avoid environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] S1, ingredients: first add liquid caustic soda with a depth of 70cm to the dosing tank, and then slowly add bromine to the liquid caustic soda until the color of the mixed solution appears reddish and no longer fades. Let it stand for 24 hours to cool down, the mixed material liquid is filtered to remove insoluble impurities, and then it is prepared to a certain concentration and poured into the electrolytic cell;

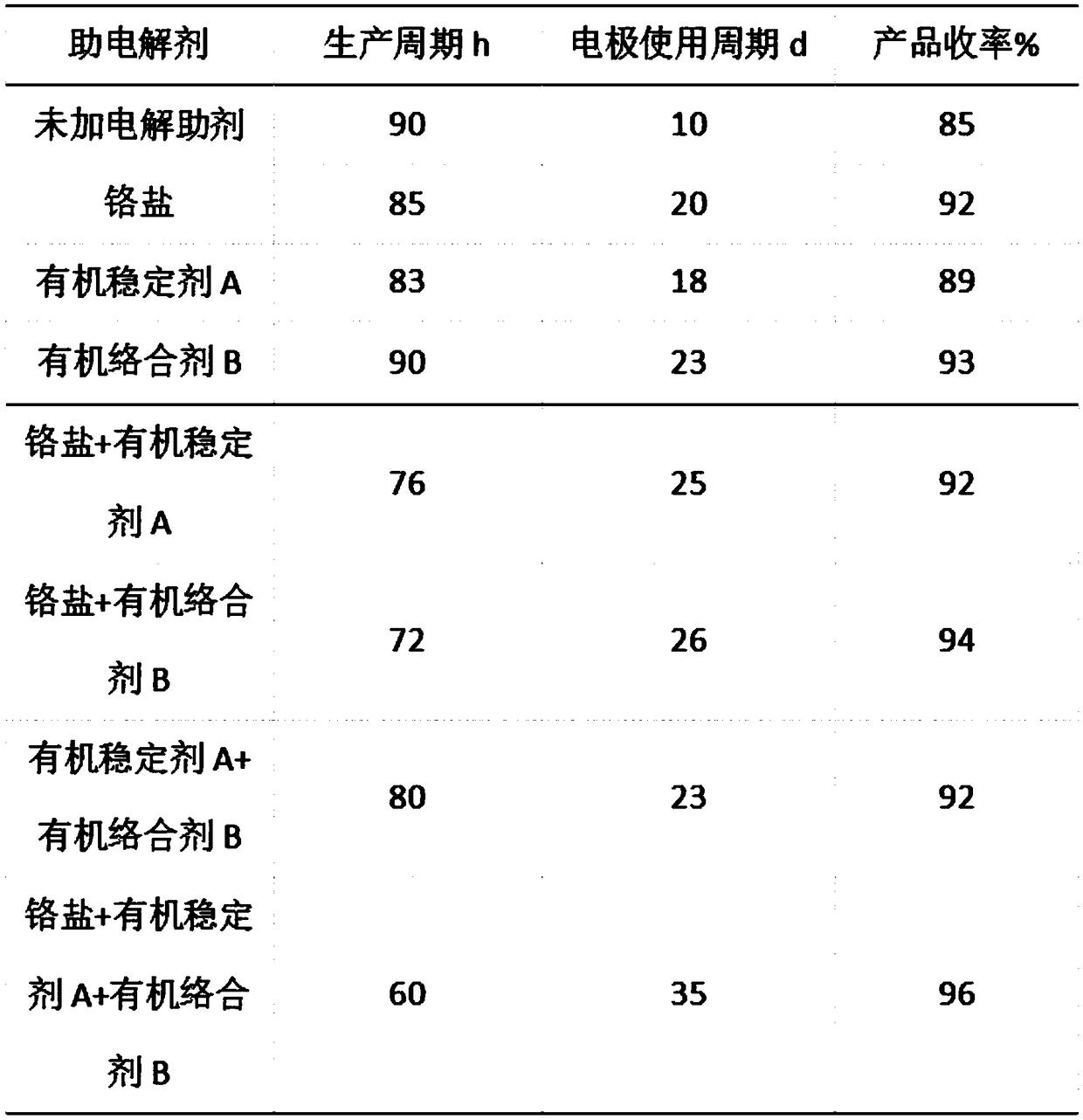

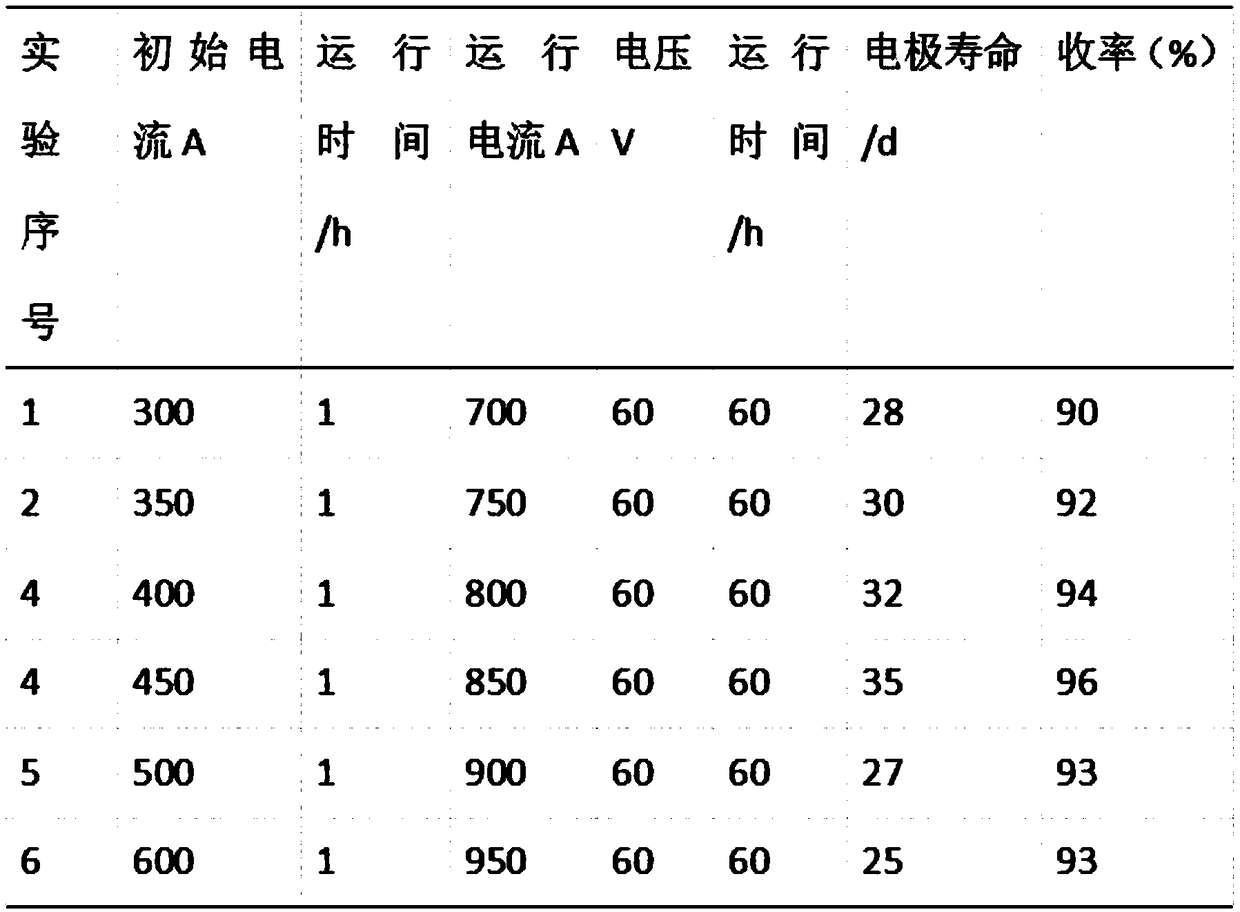

[0030] S2, electrolysis: put S1 into the filtrate in the electrolytic cell for electrolysis, add chromium salt, organic stabilizer A and organic complexing agent B in the ratio of 1.5:2:1 before electrolysis, first run at low current for 1 hour, and then Raise to the value required by the process, control the voltage at 60V, and after 60 hours of electrolysis, the workshop will notify the laboratory technician to take the mixed solution for testing, and determine the specific discharge time based on the test results. In use, the low current value of the firs...

Embodiment 2

[0036]S1, ingredients: first add liquid caustic soda with a depth of 70cm to the dosing tank, and then slowly add bromine to the liquid caustic soda until the color of the mixed solution appears reddish and no longer fades. Let it stand for 24 hours to cool down, the mixed material liquid is filtered to remove insoluble impurities, and then it is prepared to a certain concentration and poured into the electrolytic cell;

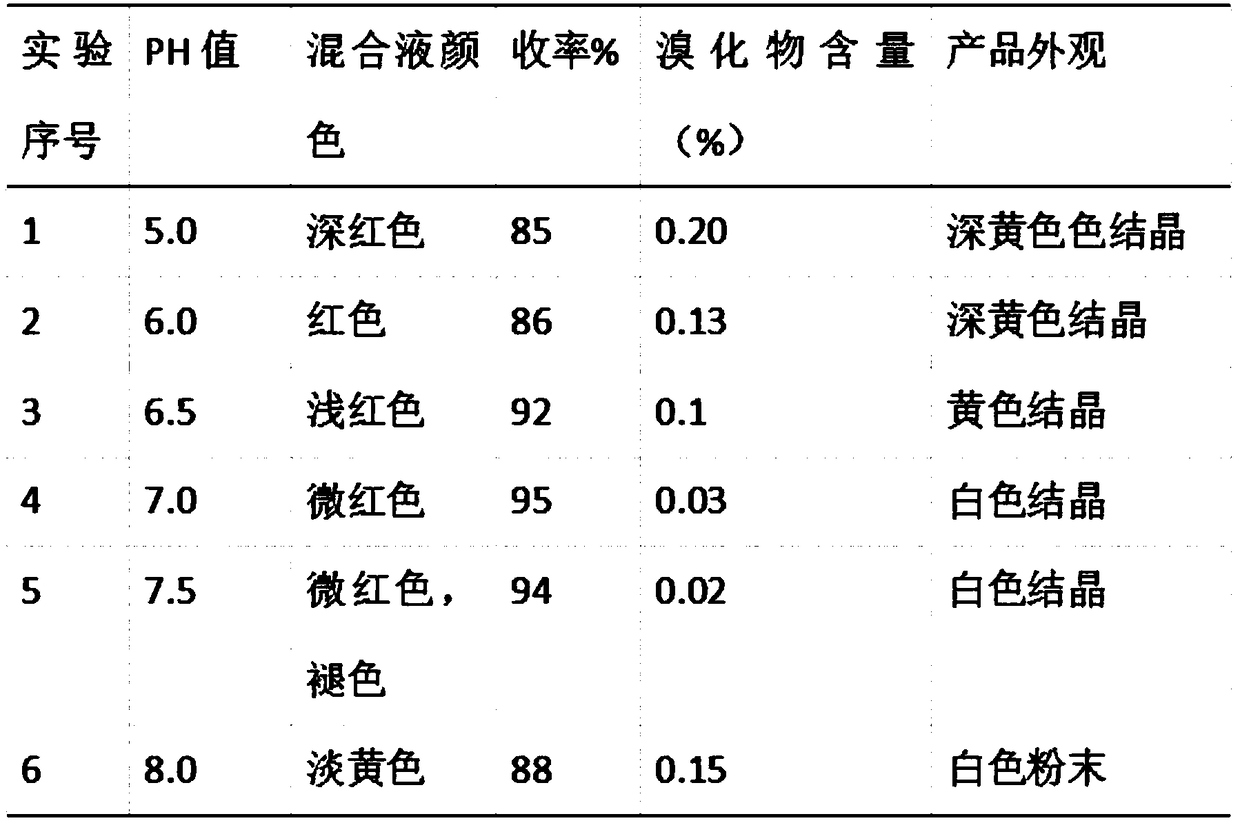

[0037] S2. Electrolysis: put S1 into the filtrate in the electrolytic cell for electrolysis, add chromium salt, organic stabilizer A and organic complexing agent B in a ratio of 1:0:0 before electrolysis, first run at low current for 1 hour, and then Raise to the value required by the process, control the voltage at 60V, and after 60 hours of electrolysis, the workshop will notify the laboratory technician to take the mixed solution for testing, and determine the specific discharge time based on the test results. After discharging, adjust the pH value of the f...

Embodiment 3

[0043] S1, ingredients: first add liquid caustic soda with a depth of 70cm to the dosing tank, and then slowly add bromine to the liquid caustic soda until the color of the mixed solution appears reddish and no longer fades. Let it stand for 24 hours to cool down, the mixed material liquid is filtered to remove insoluble impurities, and then it is prepared to a certain concentration and poured into the electrolytic cell;

[0044] S2, electrolysis: put S1 into the filtrate in the electrolytic cell for electrolysis, add chromium salt, organic stabilizer A and organic complexing agent B in a ratio of 0:1:0 before electrolysis, first run at low current for 0.5 hours, and then Raise to the value required by the process, control the voltage at 60V, and after 60 hours of electrolysis, the workshop will notify the laboratory technician to take the mixed solution for testing, and determine the specific discharge time based on the test results. After discharging, adjust the pH value of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com