Polypropylene fiber silk ribbon and preparation method thereof

A production method and technology of polypropylene yarn, applied in the manufacture of rayon, conductive/antistatic filament, conjugated synthetic polymer artificial filament, etc., can solve the problems of poor washing resistance and durability, and disappearance of antistatic properties. Achieve the effect of good antibacterial performance, strong antibacterial persistence and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

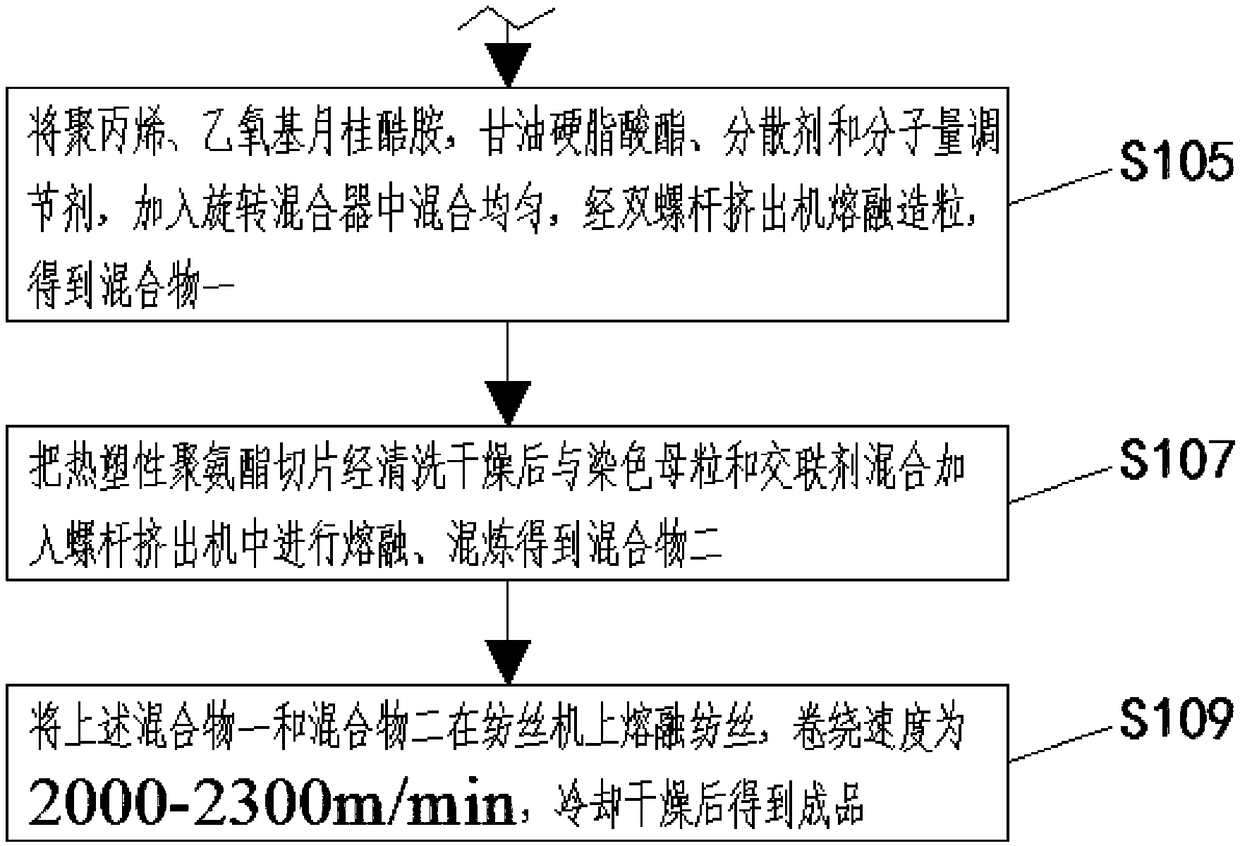

[0053] A kind of polypropylene fiber ribbon, this polypropylene fiber ribbon is made of the raw material of following mass parts:

[0054] 40g of polypropylene, 1g of ethoxylated lauramide, 0.5g of glycerol stearate, 1g of dispersant, 0.5g of molecular weight regulator, 10g of polyurethane, 2g of crosslinking agent, and 20g of dyeing masterbatch.

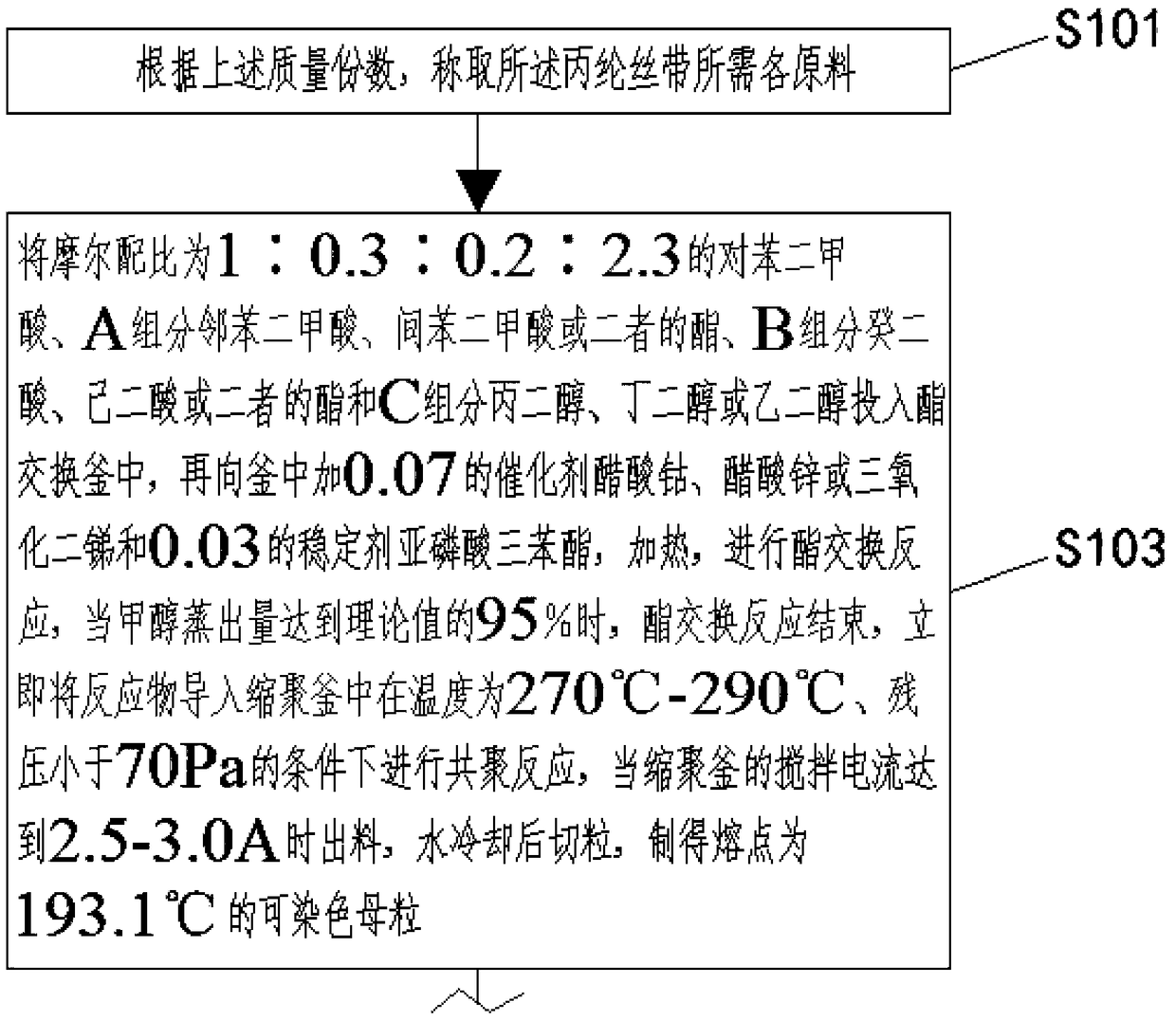

[0055] Wherein, the dyeable masterbatch includes the following raw material components: the dyeable masterbatch is terephthalic acid, A component, B component and C component with a molar ratio of 1:0.3:0.2:2.3, in It is produced by transesterification and copolymerization in a container, wherein component A includes esters of phthalic acid, isophthalic acid or both, and component B includes esters of sebacic acid, adipic acid or both, The C component includes propylene glycol, butylene glycol or ethylene glycol.

[0056] The dyeable masterbatch also includes the following raw material components: 0.02g of catalyst and 0.02g of sta...

Embodiment 2

[0066] A kind of polypropylene fiber ribbon, this polypropylene fiber ribbon is made of the raw material of following mass parts:

[0067] 48g of polypropylene, 2g of ethoxylauramide, 1g of glycerol stearate, 2g of dispersant, 1g of molecular weight regulator, 20g of polyurethane, 3g of crosslinking agent, and 25g of masterbatch.

[0068] Wherein, the dyeable masterbatch includes the following raw material components: the dyeable masterbatch is terephthalic acid, A component, B component and C component with a molar ratio of 1:0.3:0.2:2.3, in It is produced by transesterification and copolymerization in a container, wherein component A includes esters of phthalic acid, isophthalic acid or both, and component B includes esters of sebacic acid, adipic acid or both, The C component includes propylene glycol, butylene glycol or ethylene glycol.

[0069] The dyeable masterbatch also includes the following raw material components: 0.07 part of catalyst and 0.03 part of stabilizer. ...

Embodiment 3

[0080] A kind of polypropylene fiber ribbon, this polypropylene fiber ribbon is made of the raw material of following mass parts:

[0081] 55g of polypropylene, 2.5g of ethoxylauramide, 1.5g of glycerol stearate, 2.5g of dispersant, 1.5g of molecular weight regulator, 30g of polyurethane, 4g of crosslinking agent, and 30g of masterbatch.

[0082] Wherein, the dyeable masterbatch includes the following raw material components: the dyeable masterbatch is terephthalic acid, A component, B component and C component with a molar ratio of 1:0.3:0.2:2.3, in It is produced by transesterification and copolymerization in a container, wherein component A includes esters of phthalic acid, isophthalic acid or both, and component B includes esters of sebacic acid, adipic acid or both, The C component includes propylene glycol, butylene glycol or ethylene glycol.

[0083] The dyeable masterbatch also includes the following raw material components: 0.12g of catalyst and 0.04g of stabilizer. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| brittleness temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com