Universal spandex compounded emulsifier and preparation method thereof

A technology of compounding emulsifier and spandex oil agent, which is applied in textiles and papermaking, fiber treatment, fiber type, etc., can solve the problems of general processability, general stability, and high production cost in the subsequent process, and achieve simple and easy operation in the production process , Reduce production costs, the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A kind of preparation method of spandex oil general compound emulsifier, comprises the following steps:

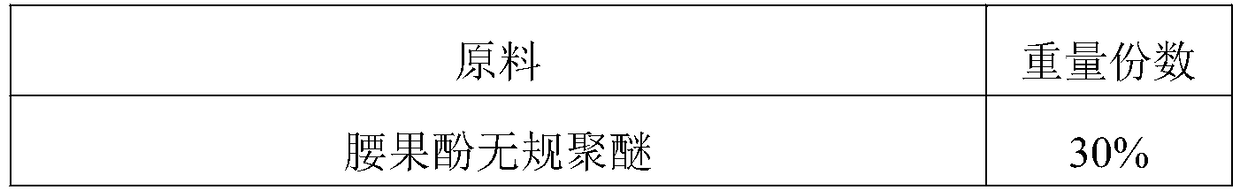

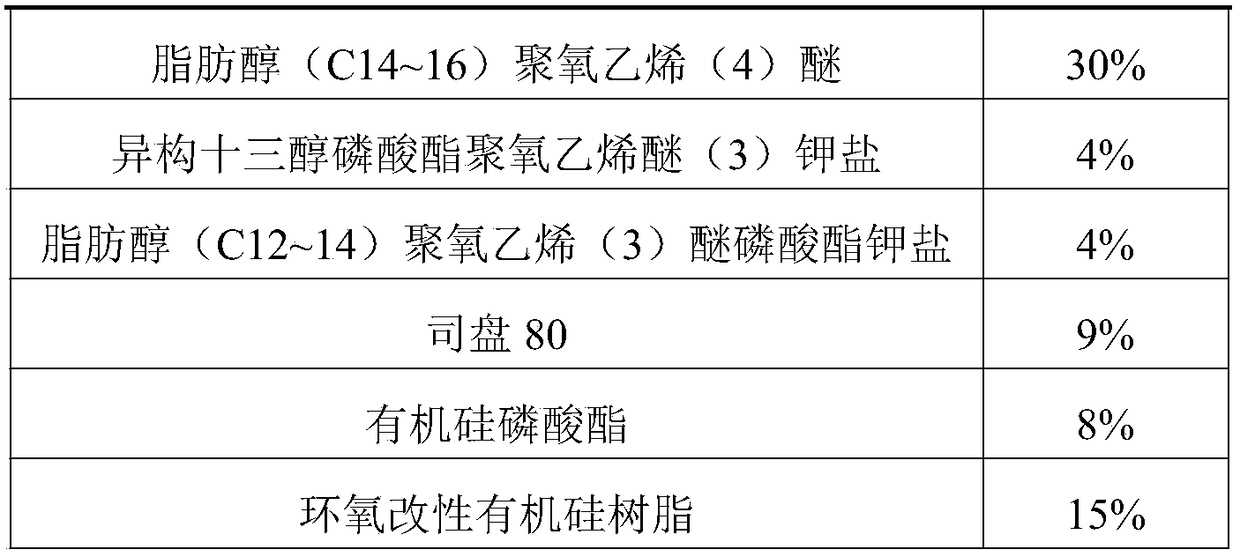

[0028] a. Weighing of materials: 30-50 parts of cardanol polyether, 20-40 parts of fatty alcohol polyoxyethylene ether, 5-15 parts of sorbitan fatty acid ester, 3-5 parts of fat Alcohol phosphate polyoxyethylene ether potassium salt, 3-5 parts of fatty alcohol polyoxyethylene ether phosphate potassium salt, 5-12 parts of organosilicon phosphate and 5-20 parts of organosilicon resin;

[0029] b. Add the materials weighed in step a) into the reaction kettle, heat to 50±2°C, and uniformly stir for 2 to 5 hours, so that the components are fully fused;

[0030] c cooling, filtering, discharging, and packaging to obtain a general compound emulsifier for spandex oil.

Embodiment 1

[0032] raw material

Embodiment 2

[0034] raw material

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com