Sulfur modified iron-manganese bimetallic oxide and preparation method and application thereof

A double metal oxide and sulfur modification technology, which is applied to chemical instruments and methods, water pollutants, and other chemical processes, can solve the problems of adsorption rate, adsorption affinity and adsorption capacity to be further improved, and achieve good removal effect , the effect of increasing the adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

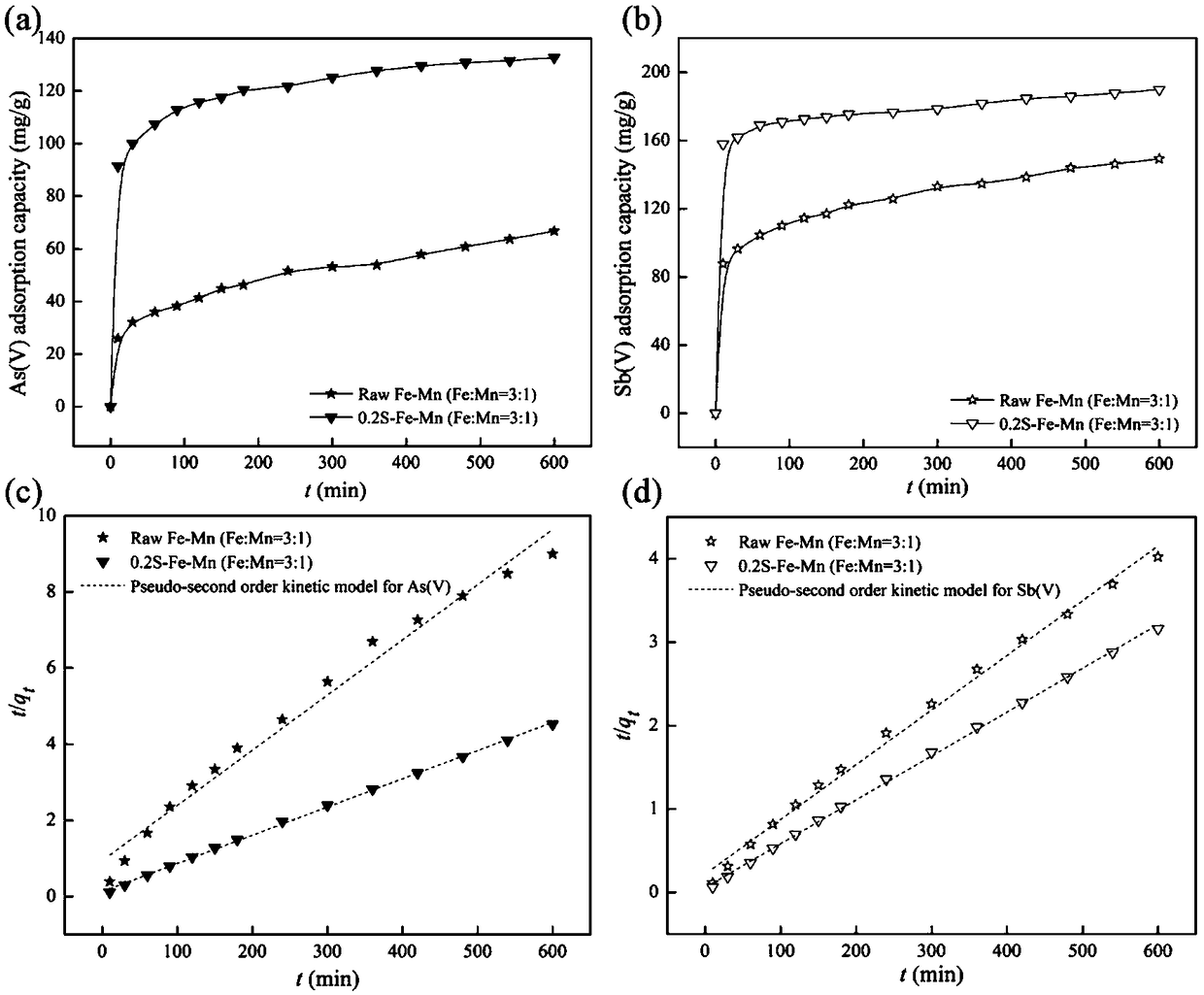

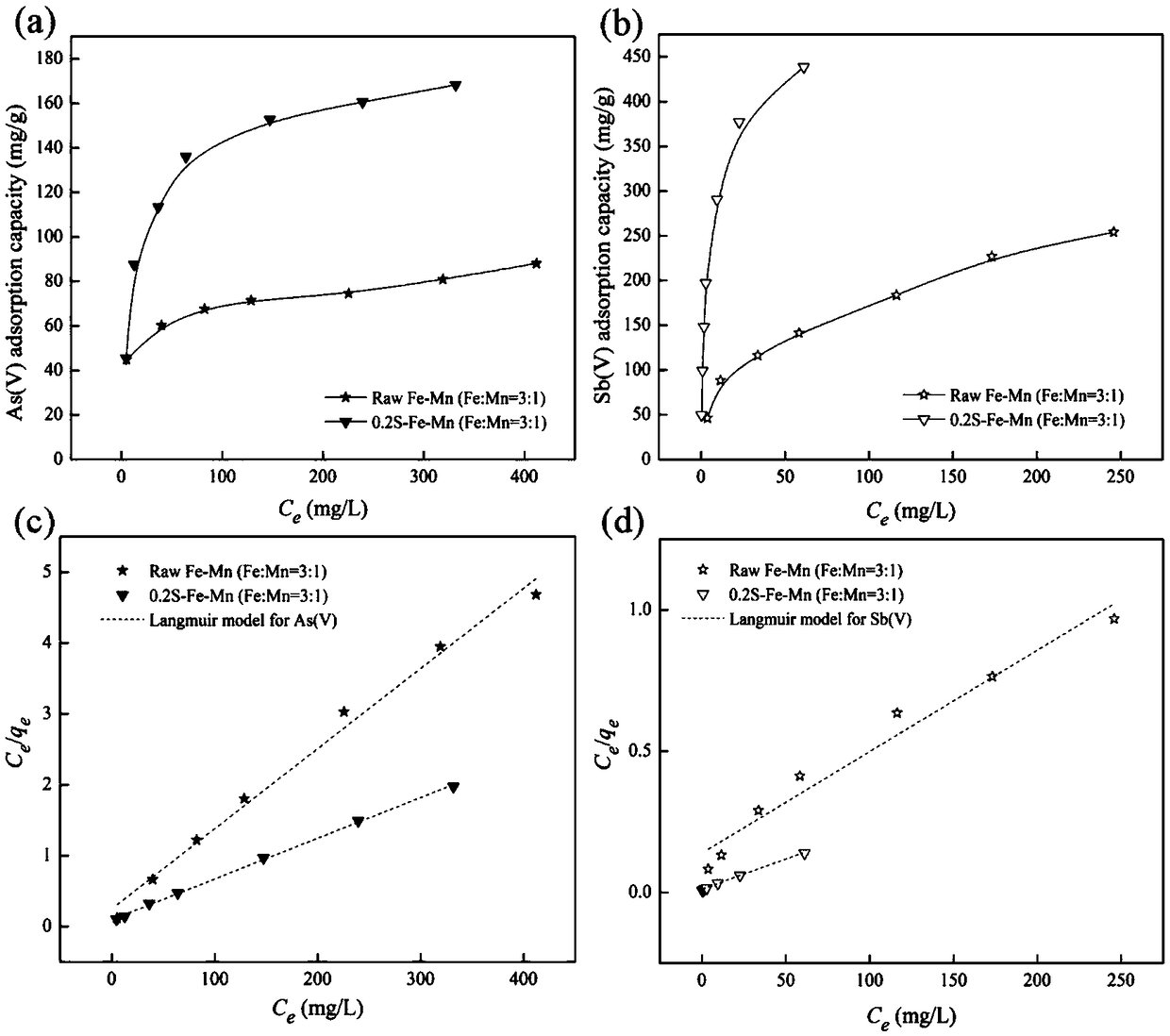

[0040]At room temperature, under nitrogen protection, dissolve 0.06mol of ferrous sulfate heptahydrate and 0.02mol of manganese acetate in 500mL of deionized water, stir them with magnetic force to completely dissolve, then add 1mol / L NaOH solution to adjust the pH to 7~ 8. After stirring vigorously for 30 minutes, add 0.002 mol of sodium dithionite, continue to stir and react for 12 hours, centrifuge the reacted suspension at 8000r / min for 5 minutes, wash the precipitate repeatedly with anaerobic deionized water and absolute ethanol, and place in a vacuum Dry in a drying oven at 60°C to constant weight, grind and sieve to obtain a sulfur-modified iron-manganese bimetallic oxide, wherein the molar ratio of S:Fe:Mn is 0.2:3:1, which is recorded as 0.2S-Fe- Mn (Fe:Mn=3:1). The preparation method of the iron-manganese double metal oxide material without adding sodium dithionite is the same as above, which is recorded as Raw Fe-Mn (Fe:Mn=3:1).

[0041] Table 1. Kinetic parameter...

Embodiment 2

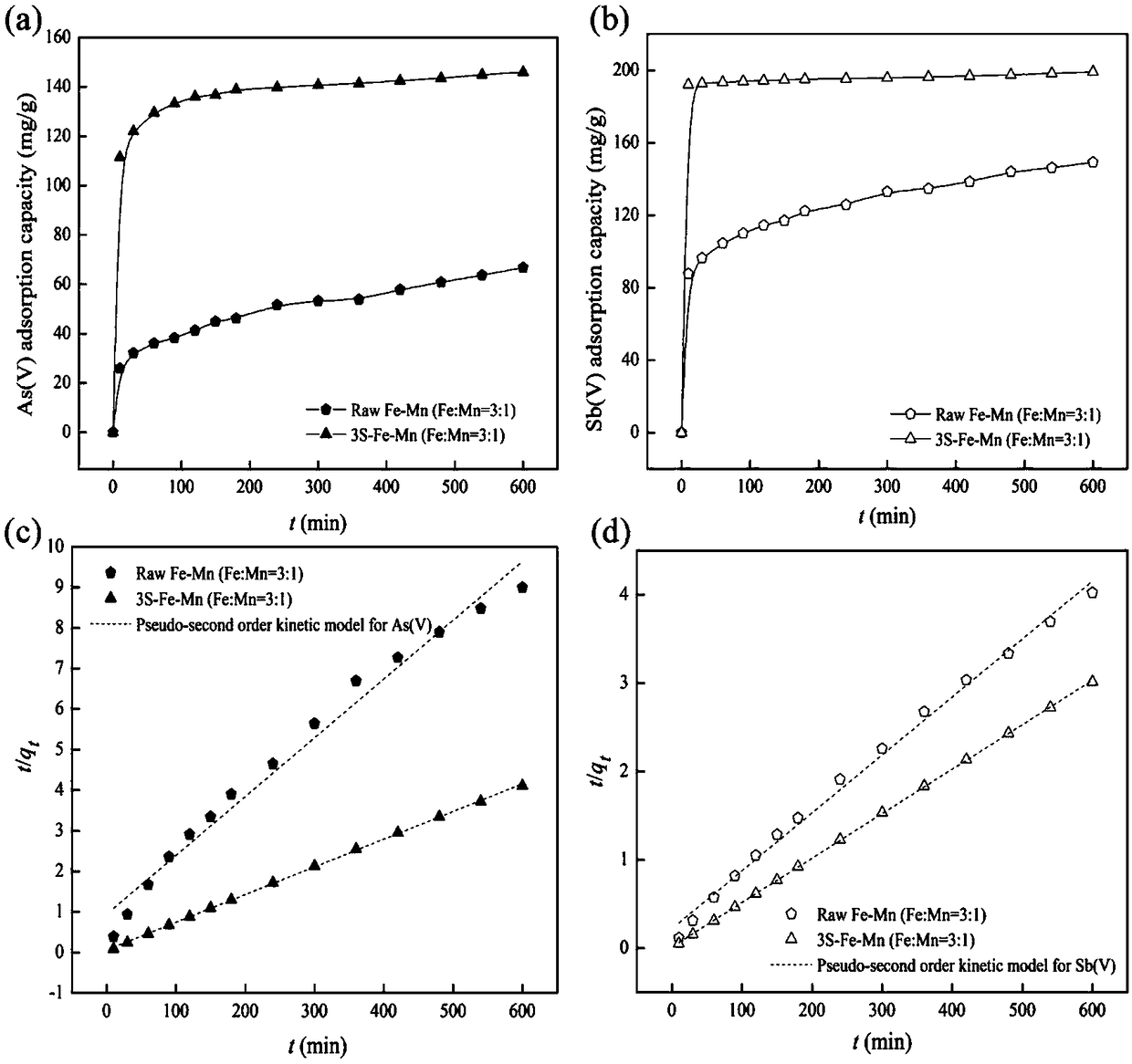

[0047] At room temperature, 0.03 mol of ferrous sulfate heptahydrate and 0.01 mol of manganese acetate were dissolved in 200 mL of deionized water under the protection of nitrogen, and magnetically stirred to completely dissolve, and then ammonia solution was added to adjust the pH to 7-8. After stirring vigorously for 30 minutes, add 0.03 mol of sodium sulfide, continue to stir the mixed solution at 90°C for 24 hours, centrifuge the reacted suspension at 8000r / min for 5 minutes, and then use anaerobic deionized water and absolute ethanol repeatedly Wash, place in a vacuum drying oven at 60°C and dry to constant weight, grind and sieve to obtain a black deposit that is a sulfur-modified iron-manganese double metal oxide, wherein the molar ratio of S:Fe:Mn is 3:3: 1, recorded as 3S-Fe-Mn (Fe:Mn=3:1). The preparation method of the iron-manganese double metal oxide material without adding sodium bisulfide is the same as that in Example 1, which is recorded as Raw Fe-Mn (Fe:Mn=3:1...

Embodiment 3

[0054] At room temperature, under nitrogen protection, dissolve 0.10mol of ferrous chloride and 0.01mol of manganese nitrate in 200mL of deionized water, stir them with magnetic force to completely dissolve, then add 1mol / L of KOH solution to adjust the pH at 7-8 . After stirring vigorously for 30 minutes, add 0.01 mol of sodium dithionite, continue to stir the mixed solution at room temperature for 48 hours, transfer the reacted suspension to centrifuge at 8000r / min for 5 minutes, and then use anaerobic deionized water and absolute ethanol Wash repeatedly, dry in a vacuum drying oven at 60°C to constant weight, grind and sieve to obtain black deposits that are sulfur-modified iron-manganese double metal oxides, wherein the molar ratio of S:Fe:Mn is 2:10 :1, recorded as 2S-Fe-Mn (Fe:Mn=10:1). The preparation method of the iron-manganese double metal oxide material without adding sodium dithionite is the same as above, which is recorded as Raw Fe-Mn (Fe:Mn=10:1).

[0055] Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption rate | aaaaa | aaaaa |

| Adsorption rate | aaaaa | aaaaa |

| Adsorption rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com