P*S*A grade retarded cement and preparation method thereof as well as concrete road

A retarding and cement technology, applied in the direction of roads, roads, cement production, etc., can solve the problem of insufficient cement retarding time, and achieve the effect of high strength growth rate, good durability and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

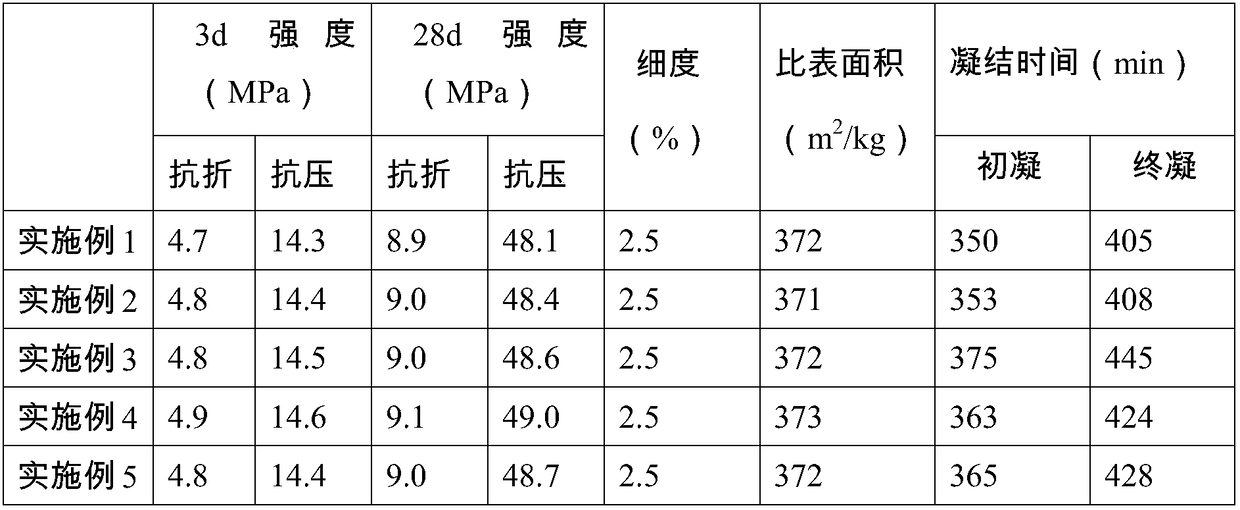

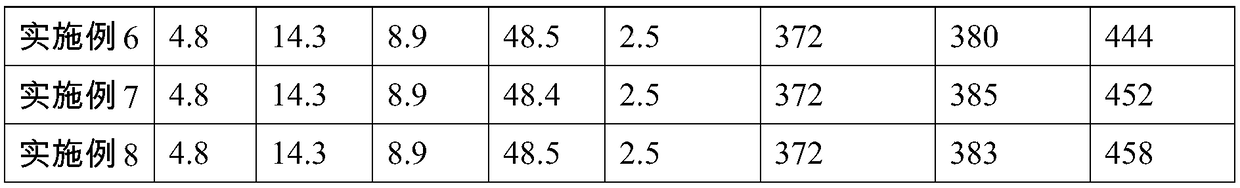

Examples

preparation example Construction

[0026] A preparation method of P·S·A grade retarded cement, comprising mixing and grinding Portland cement clinker, granulated blast furnace slag powder, fly ash and desulfurized gypsum to obtain P·S·A grade retarded cement cement. Preferably, the mixed grinding has a specific surface area of 340-400m 2 / kg of powder. Then it is transported to the cement silo by the hoist for storage. The pavement paved with cement in this fineness range is not prone to cracks.

[0027] A preparation method of P·S·A grade retarded cement, comprising grinding Portland cement clinker to obtain Portland cement clinker fine powder, and grinding granulated blast furnace slag powder to obtain granulated blast furnace slag Grinding fly ash to get fly ash fine powder, grinding desulfurized gypsum to get desulfurized gypsum fine powder, then Portland cement clinker fine powder, granulated blast furnace slag fine powder, pulverized coal Ash fine powder and desulfurized gypsum fine powder are mixed...

Embodiment 1

[0031] A P·S·A grade retarded cement, the mass percentage of raw materials is composed of 51% Portland cement clinker, 37% granulated blast furnace slag powder, 6% fly ash and 6% desulfurized gypsum. Among them, the components in Portland cement clinker include 3.8:218.9:45.6:31.8:661.4:33.2:5:0.23 LOSS, SiO 2 、Al 2 o 3 , Fe 2 o 3 , CaO, MgO and SO 3 . The components in fly ash include: 98:380:380:53.8:48.7:5.3:29.3:0.2 LOSS, SiO 2 、Al 2 o 3 , Fe2 o 3 , CaO, MgO, SO 3 and Cl - . The loss on ignition of granulated blast furnace slag powder is -0.7%, and the medium SiO 2 、Al 2 o 3 , Fe 2 o 3 , CaO, MgO, SO 3 and Cl - The mass ratio is: 350:155:16:380:90:7.5:0.3.

[0032] A preparation method of P·S·A grade retarded cement. Take 510kg of Portland cement clinker, 370kg of granulated blast furnace slag powder, 60kg of fly ash, and 60kg of desulfurized gypsum, and grind them in a cement mill to obtain The specific surface area is 340~400m 2 / kg powder is P·S·A g...

Embodiment 2

[0034] A P·S·A grade retarded cement, the mass percentage of raw materials is composed of 59% Portland cement clinker, 32% granulated blast furnace slag powder, 4% fly ash and 6% desulfurized gypsum. Among them, the components in Portland cement clinker include: 4:218:46.5:30:663:33.5:4.5:0.2 LOSS, SiO 2 、Al 2 o 3 , Fe 2 o 3 , CaO, MgO, SO 3 and Cl - . The components in fly ash include: 90:400:350:54.2:47:5.5:29.6:0.2 LOSS, SiO 2 、Al 2 o 3 , Fe 2 o 3 , CaO, MgO, SO 3 and Cl - . The loss on ignition of granulated blast furnace slag powder is -0.65%, and the medium SiO of granulated blast furnace slag powder 2 、Al 2 o 3 , Fe 2 o 3 , CaO, MgO, SO 3 and Cl - The mass ratio is: 300:165:14:430:80:8.5:0.2.

[0035] A preparation method of P.S.A grade retarded cement. Take 590kg of the above Portland cement clinker, 320kg of granulated blast furnace slag powder, 40kg of fly ash, and 60kg of desulfurized gypsum, and grind them in a cement mill to obtain The specif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com