Cement grinding aid

A cement grinding aid and catalyst technology, applied in the field of cement grinding aids, can solve problems such as poor adaptability, and achieve the effects of good grinding aid effect, increasing diffusion rate and improving early performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

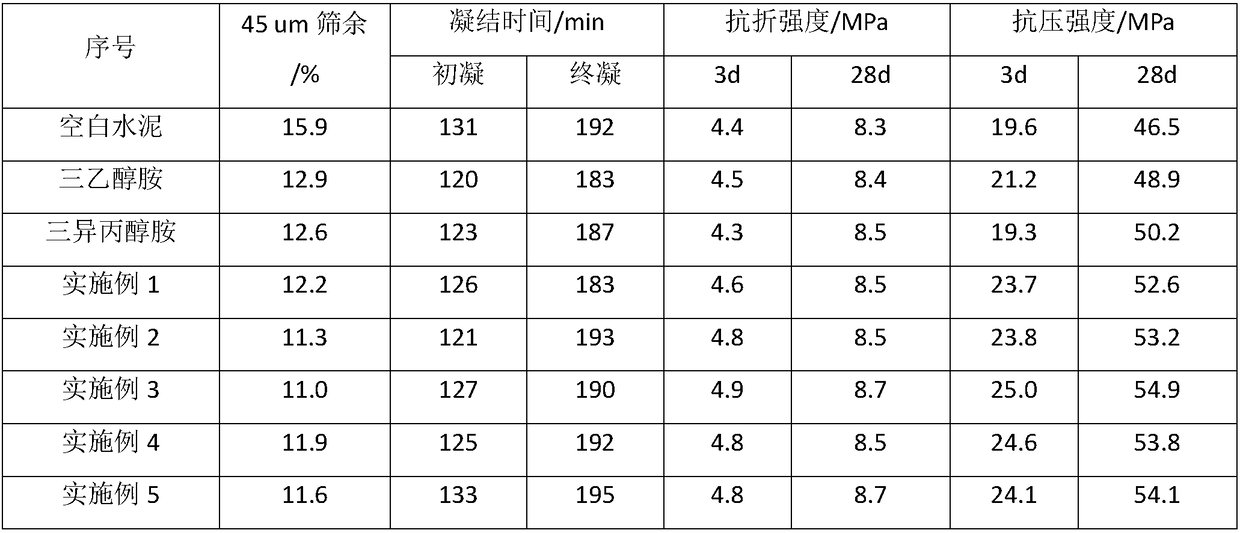

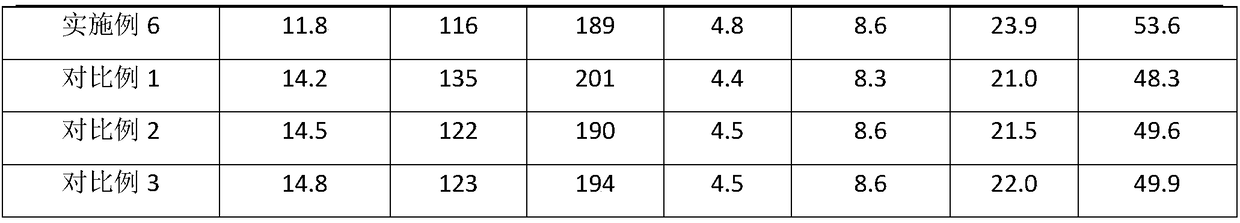

Examples

Embodiment 1

[0020] A cement grinding aid is composed of the following raw materials in parts by weight: 40 parts of nitrilotriacetic acid and ethylene glycol reactant, 20 parts of isooctanyl phosphate, 15 parts of alcohol amine compound, and 8 parts of surfactant; The reactant of nitrilotriacetic acid and ethylene glycol is prepared by the following method: adding ethylene glycol in molar ratio: nitrilotriacetic acid=0.8:1 into the reactor, and then adding 2% of the total mass of nitrilotriacetic acid and ethylene glycol Catalyst, stirred, heated up to 120°C for 4 hours of constant temperature reaction, and lowered to room temperature to obtain the reactant of nitrilotriacetic acid and ethylene glycol.

[0021] The catalyst is sulfamic acid.

[0022] The isooctyl phosphate is isooctyl phosphate monoester.

[0023] The alcohol amine compound is diethanol monoisopropanolamine.

[0024] The surfactant is polyoxyethylene octylphenol ether.

Embodiment 2

[0026] A cement grinding aid, which is composed of the following raw materials in parts by weight: 55 parts of nitrilotriacetic acid and ethylene glycol reactant, 15 parts of isooctyl phosphate, 20 parts of alcohol amine compound, and 3 parts of surfactant; The reactant of nitrilotriacetic acid and ethylene glycol is prepared by the following method: adding ethylene glycol in molar ratio: nitrilotriacetic acid=1.5:1 into the reactor, and then adding 0.5% of the total mass of nitrilotriacetic acid and ethylene glycol Catalyst, stirred, heated up to 150°C for 3 hours at a constant temperature, and cooled down to room temperature to obtain the reactant of nitrilotriacetic acid and ethylene glycol.

[0027] The catalyst is concentrated sulfuric acid.

[0028] The isooctyl phosphate is isooctyl phosphate diester.

[0029] The alcohol amine compound is monoethanol diisopropanolamine.

[0030] The surfactant is polyvinylpyrrolidone.

Embodiment 3

[0032] A cement grinding aid, which is composed of the following raw materials in parts by weight: 50 parts of nitrilotriacetic acid and ethylene glycol reactant, 18 parts of isooctyl phosphate, 17 parts of alcohol amine compound, and 5 parts of surfactant; The reaction product of nitrilotriacetic acid and ethylene glycol is prepared by the following method: adding 1% of the total mass of nitrilotriacetic acid and ethylene glycol into the reactor at a molar ratio of ethylene glycol: nitrilotriacetic acid = 1:1 Catalyst, stirred, heated up to 130°C for 3.5 hours at a constant temperature, and cooled down to room temperature to obtain the reactant of nitrilotriacetic acid and ethylene glycol.

[0033] The catalyst is boric acid.

[0034] The isooctyl phosphate is formed by mixing isooctyl phosphate diester and isooctyl phosphate monoester according to a molar ratio of 2.5:1.

[0035] The alcohol amine compound is monoethanol diisopropanolamine.

[0036] The surfactant is sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com