Castable for reducing atmosphere kiln

A castable and kiln technology, applied in the field of refractory materials, can solve problems such as wasting energy and affecting normal production, and achieve the effects of avoiding abnormal looseness, high resistance to CO erosion, and strong room temperature hardening ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

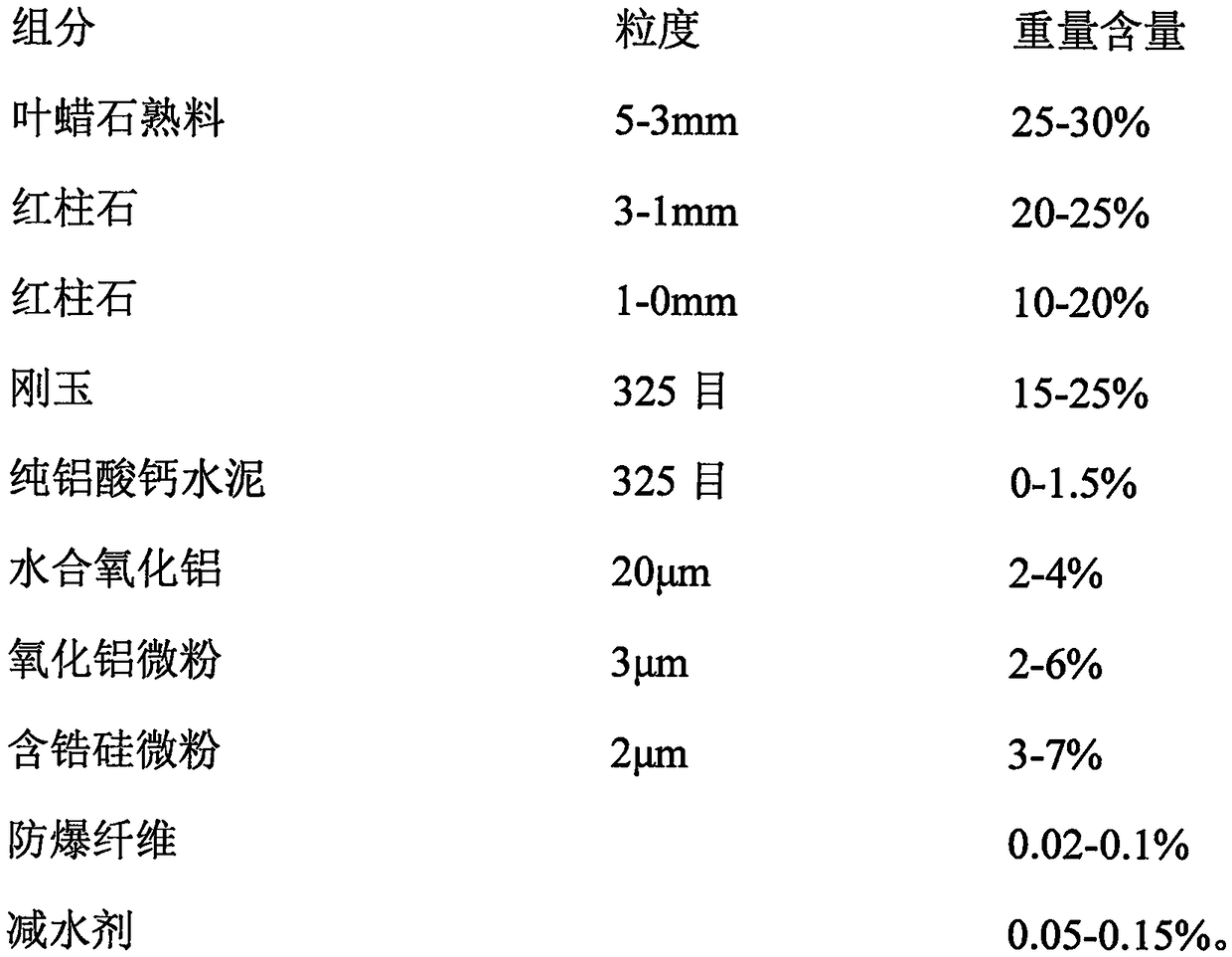

[0029] Castable formula for reducing atmosphere kiln:

[0030] Component Particle Size Weight Content

[0031] Pyrophyllite clinker 5-3mm 28%

[0032] Andalusite 3-1mm 22%

[0033] Andalusite 1-0mm 17%

[0034] Tabular alumina 325 mesh 18.45%

[0035] Ammann CA270 cement 325 mesh 0.5%

[0036] Hydrated alumina 20μm 3%

[0037] α-alumina fine powder 3μm 5%

[0038] Zirconium silicon powder 2μm 6%

[0039] Explosion-proof fiber 0.05%

[0040] CASTAMENT FS20 0.1%.

[0041] The main physical and chemical indicators of the castable for the reducing atmosphere kiln in this embodiment are:

[0042] Chemical Composition: Al 2 o 3 56.1%, SiO 2 42.6%, Fe 2 o 3 0.36%;

[0043] Matrix mineral phase composition: After firing at 1450°C, the matrix XRD results show that the main crystal phase is mullite;

[0044] Thermal Shock Resistance: Water cooling at room temperature, 56 thermal shocks.

[0045] Resistance to CO erosion: The test standard adopts the American "Test Met...

Embodiment 2

[0047] Castable formula for reducing atmosphere kiln:

[0048] Component Particle Size Weight Content

[0049] Pyrophyllite clinker 5-3mm 30%

[0050] Andalusite 3-1mm 20%

[0051] Andalusite 1-0mm 17%

[0052] White corundum 325 mesh 19.39%

[0053] Ammann CA670 cement 325 mesh 1%

[0054] Hydrated alumina 20μm 2.5%

[0055] α-alumina fine powder 3μm 4%

[0056] Zirconium silicon powder 2μm 6%

[0057] Explosion-proof fiber 0.03%

[0058] CASTAMENT FS20 0.08%.

[0059] The main physical and chemical indicators of the castable for the reducing atmosphere kiln in this embodiment are:

[0060] Chemical Composition: Al 2 o 3 55.2%, SiO 2 43.3%, Fe 2 o 3 0.37%;

[0061] Matrix mineral phase composition: After firing at 1450°C, the matrix XRD results show that the main crystal phase is mullite;

[0062] Thermal Shock Resistance: Water cooling at room temperature, 53 thermal shocks.

[0063] Resistance to CO erosion: The test standard adopts the American "Test Met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com