Polypropylene composition and preparation method thereof

A technology of polypropylene composition and polypropylene resin, which is applied in the field of polypropylene composition and its preparation, can solve problems such as high processing temperature, pitting on the surface of the material, and reduce gloss, and achieve good mechanical properties, increase toughness, and reduce gloss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

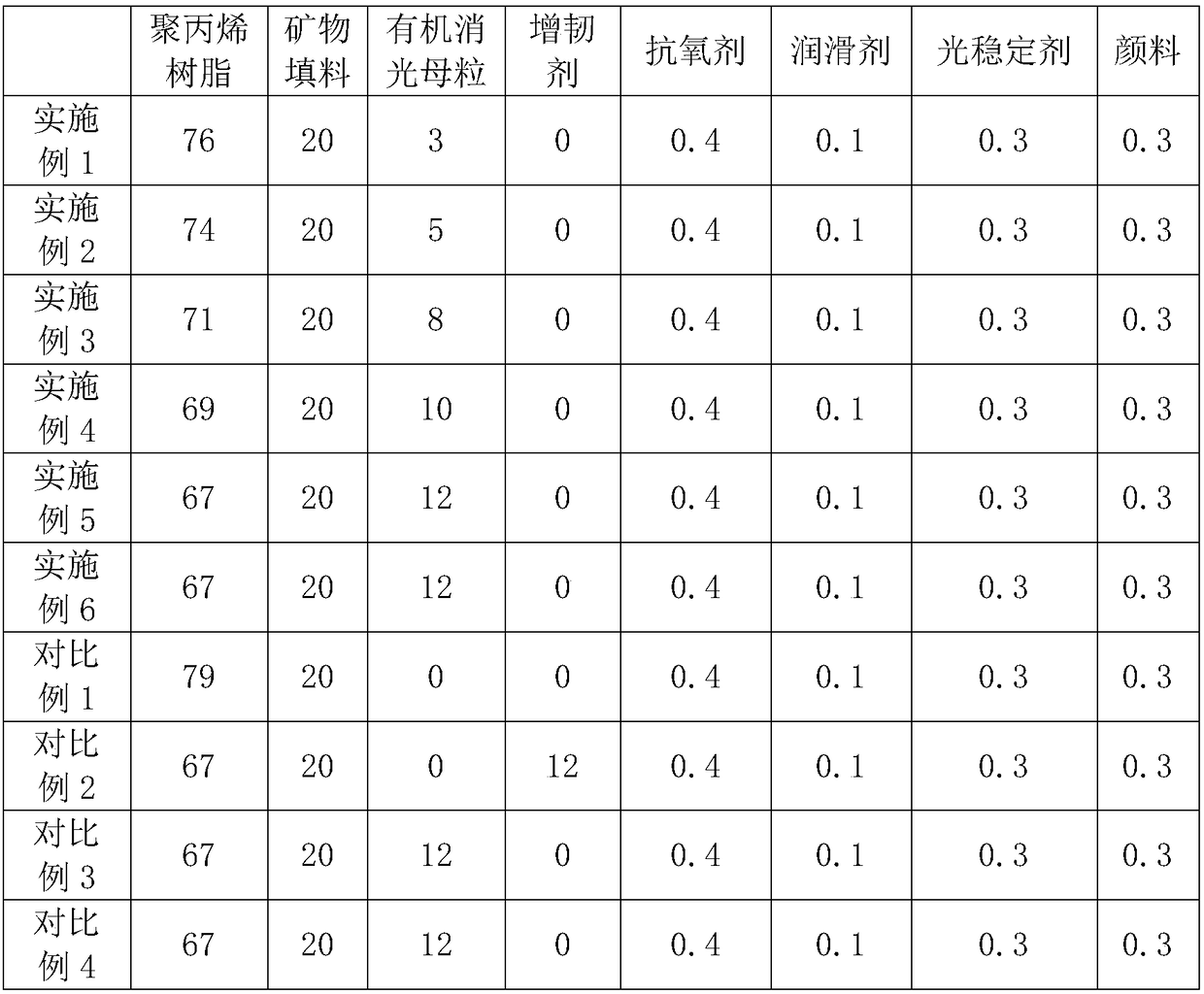

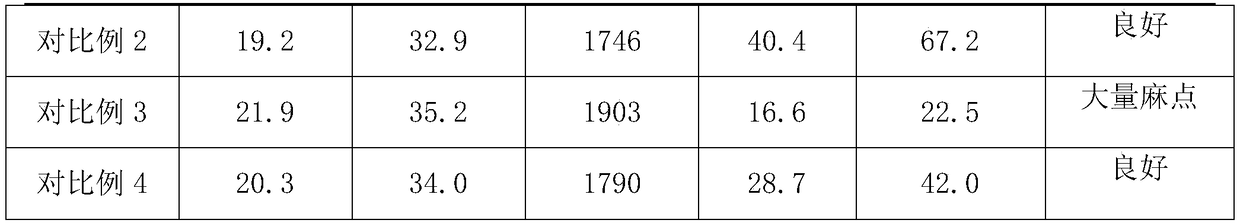

Examples

preparation example Construction

[0041] Among the raw materials for the preparation of the above-mentioned organic matting masterbatch, preferably, the Mooney viscosity of the EPDM rubber is greater than 60 under the test condition of ML(1+4)125°C, which can realize the organic matting masterbatch to a certain extent It has a greater gel content, better reduce the gloss of polypropylene, and better toughen polypropylene; preferably, the molecular weight of high-density polyethylene is greater than 500,000; high-density polyethylene at 190 ° C, 2.16KG The melt flow rate under the test conditions is less than 2g / 10min, which can achieve a better synergistic effect with EPDM rubber, better reduce gloss, and toughen polypropylene at the same time.

[0042] In some of the embodiments, the gel content of the organic matting masterbatch is 50-60%.

[0043] In some of these embodiments, the crosslinking agent is dicumyl peroxide.

[0044] In some of the embodiments, the polypropylene resin is copolymerized polypropy...

Embodiment 1

[0073] Preparation of organic matting masterbatch:

[0074] Mix 75 parts of high-density polyethylene (Lanzhou Petrochemical 5000S), 25 parts of EPDM rubber (Mitsui 3092), 0.15 parts of crosslinking agent, 0.1 part of lubricant, and 0.3 part of antioxidant, and mix them evenly through an extruder. The organic matt masterbatch can be obtained by melt blending, extruding and pelletizing. The screw speed of the extruder is 550 rpm, and the extrusion temperature is 220°C. There are 18 shear blocks in the extruder screw, of which 13 are reverse shear blocks. The gel content of the prepared organic matting masterbatch was 56%.

[0075] The polypropylene composition described in this implementation consists of the following components by weight: 76 parts of polypropylene resin PP K7227, 20 parts of talcum powder KCM 6300, 3 parts of the above-mentioned organic matting masterbatch, 0.2 part of antioxidant 1010, 0.2 part Antioxidant 168, 0.1 part of lubricant zinc stearate, 0.3 part...

Embodiment 2

[0081] A polypropylene composition is made up of the following components by weight: 74 parts of polypropylene resin PP K7227, 20 parts of talcum powder KCM 6300, 5 parts of organic matting masterbatch prepared in Example 1, 0.2 part of antioxidant 1010, 0.2 part of antioxidant 168, 0.1 part of lubricant zinc stearate, 0.3 part of light stabilizer UV-3808PP5, 0.3 part of carbon black.

[0082] See Example 1 for the preparation method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com