Abrasion-resistant rubber

A technology of wear-resistant rubber and phenyl silicone rubber, applied in the field of wear-resistant rubber, can solve the problems of easy wear and high cost, and achieve the effects of improved wear resistance, high service temperature and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

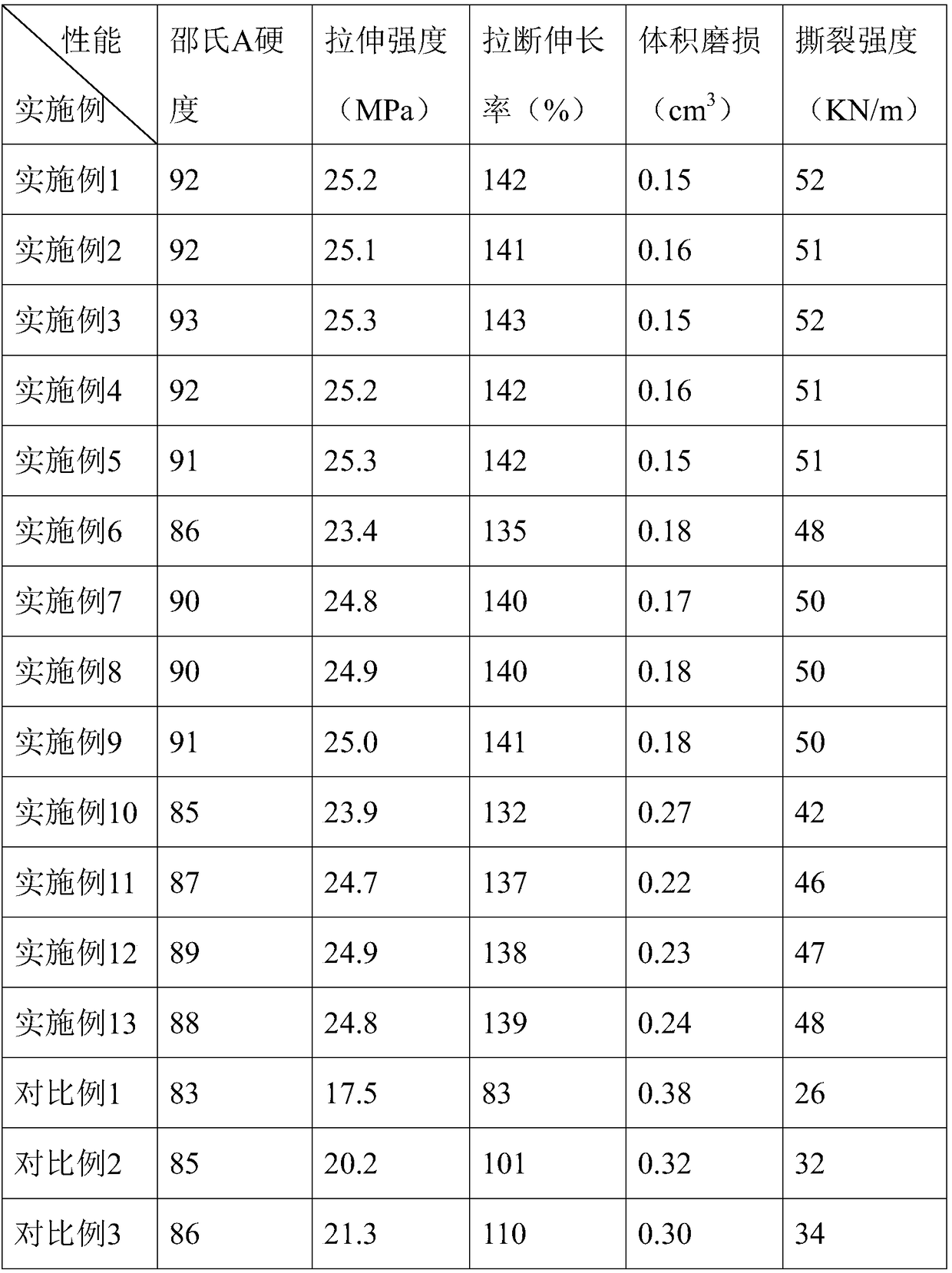

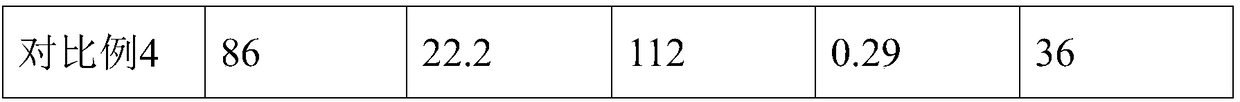

Examples

Embodiment 1

[0024] Ingredients: Weigh the components of the wear-resistant rubber and their parts by weight to weigh the raw materials; the wear-resistant rubber includes the following parts by weight: phenyl silicone rubber: 60 parts, polypropylene 20 parts, glass-ceramic particles 10 parts Parts, Shajiang Black Soil: 40 parts, Pr 2 o 3 5 parts, 5 parts of antioxidant, 5 parts of lubricant, described phenyl silicone rubber is high phenyl silicone rubber, and the diameter of glass-ceramic particle in wear-resistant rubber is 10nm, and the particle diameter of sand ginger black soil is 20 μ m, and the anti- The oxygen agent is pomegranate seed antioxidant;

[0025]One-stage vulcanization: Put the phenyl silicone rubber into the double-roller mill and knead it evenly, then put other raw materials into the mold and pressurize it with a flat vulcanizer for one-stage vulcanization to obtain a wear-resistant rubber semi-finished product ; Wherein, the phenyl silicone rubber needs to be pre-vu...

Embodiment 2

[0028] Ingredients: Weigh the components of the wear-resistant rubber and their parts by weight to weigh the raw materials; the wear-resistant rubber includes the following parts by weight: phenyl silicone rubber: 62 parts, polypropylene 25 parts, glass-ceramic particles 12 parts Parts, Shajiang Black Soil: 45 parts, Pr 2 o 3 7 parts, 6 parts of antioxidant, 6 parts of lubricant, described phenyl silicone rubber is high phenyl silicone rubber, and the diameter of glass-ceramic particle in wear-resistant rubber is 12nm, and the particle diameter of sand ginger black soil is 22 μ m, and the anti- The oxygen agent is grape seed antioxidant;

[0029] One-stage vulcanization: Put the phenyl silicone rubber into the double-roller mill and knead it evenly, then put other raw materials into the mold and pressurize it with a flat vulcanizer for one-stage vulcanization to obtain a wear-resistant rubber semi-finished product ; Wherein, the phenyl silicone rubber needs to be pre-vulcani...

Embodiment 3

[0032] Ingredients: Weigh the components of the wear-resistant rubber and their parts by weight to weigh the raw materials; the wear-resistant rubber includes the following parts by weight: phenyl silicone rubber: 70 parts, polypropylene 30 parts, glass-ceramic particles 15 parts Parts, Shajiang Black Soil: 50 parts, Pr 2 o 3 7.5 parts, 7.5 parts of antioxidant, 7.5 parts of lubricant, described phenyl silicone rubber is high phenyl silicone rubber, and the diameter of glass-ceramic particle in wear-resistant rubber is 15nm, and the particle diameter of sand ginger black soil is 25 μ m, and the anti- The oxygen agent is pomegranate seed antioxidant and grape seed antioxidant;

[0033] One-stage vulcanization: Put the phenyl silicone rubber into the double-roller mill and knead it evenly, then put other raw materials into the mold and pressurize it with a flat vulcanizer for one-stage vulcanization to obtain a wear-resistant rubber semi-finished product ; Wherein, the phenyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com