Washing liquid composition prepared from fruit and vegetable wastes and preparation method thereof

A technology for fruit and vegetable waste and washing liquid, which is applied in the field of washing and cleaning, can solve the problems of restricting the utilization of fruit and vegetable waste, high production cost, and many enzyme impurities, and achieves the effects of improving comprehensive utilization efficiency, good fertilizer effect, and improving enzyme yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

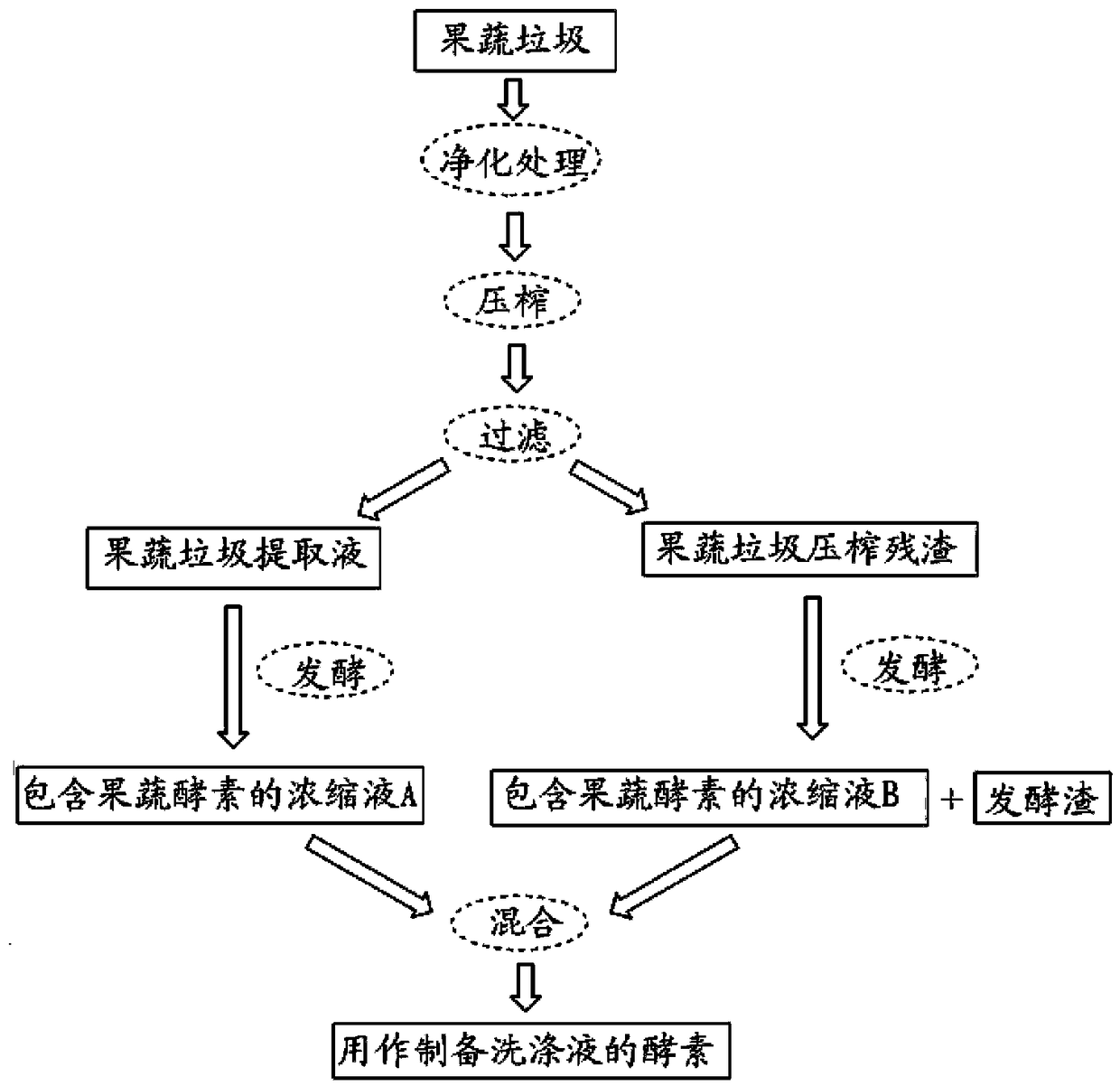

[0087] refer to figure 1 , get orange processing waste material (comprising orange peel and broken orange fruit), carry out mechanical pressing, obtain orange extract, add yeast and bacillus mixture in the ratio of 0.1% by the mass percentage of extract, the mixing ratio of the two active units is 1 : 3, closed fermentation at 35°C for 5 days to obtain a solution containing fruit and vegetable enzymes, then extract the fruit and vegetable enzymes with ethyl acetate, and concentrate the extract to obtain concentrated solution A containing fruit and vegetable enzymes after removing residual bacteria by ultrafiltration. Sterilize the residue after pressing the fruit and vegetable waste in an autoclave at 100°C for 5-10 minutes, inoculate Aspergillus niger after cooling to room temperature, and then carry out solid-state fermentation at 30°C for 72 hours, and then add pH The sodium citrate buffer solution of about 4.5 is used for enzyme extraction, potassium phosphate is added to ...

Embodiment 2

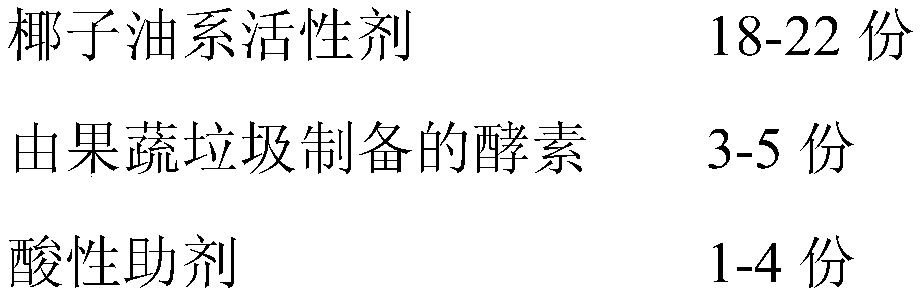

[0089] A kind of enzyme cleaning solution prepared from fruit and vegetable garbage with multiple functions, its main active components and their mass parts are:

[0090]

[0091] Natural coconut oil sodium hydroxyethyl sulfate (SCI) anionic surfactant; lauric acid and citric acid are acidic additives; p-chloro-m-xylenol and triclosan are fungicides; EDTA-2Na is a chelating agent. The preparation method of the enzyme washing liquid with multiple functions prepared from fruit and vegetable waste is as follows: add measured deionized water and various components, stir to dissolve, filter through a 300-mesh filter screen and pack.

[0092] Compared with not recycling orange processing waste, the method can reduce the cost of washing liquid by 5-10% after calculation, which is particularly meaningful in the washing liquid manufacturing industry. The washing liquid has a natural aromatic smell, which was evaluated by 8 perfumers. The score of the fragrance coordination index was...

Embodiment 3

[0094] According to the same preparation method as in Example 2, the enzyme washing liquid prepared from fruit and vegetable garbage with various functions of the following main active components and mass parts was prepared

[0095]

[0096] Fatty acid polyoxyethylene ester (LAE-9) is a low-foaming surfactant, fatty alcohol polyoxyethylene (7) ether (AEO-7), and sodium coconut oil hydroxyethyl sulfate (SCI) are anionic surfactants; twelve Alkyl betaine (BS-12) is a zwitterionic surfactant; Lauric acid and citric acid are acidic additives; p-chloro-m-xylenol and triclosan are fungicides; EDTA is a chelating agent, and the preparation process is the same as in the examples 2.

[0097] The various functions prepared in Examples 2 and 3 were used for the cleaning of clothes by using the enzyme washing liquid prepared from fruit and vegetable waste, and it was found that the product has various effects such as decontamination, suppleness, anti-static color protection, and low en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com