Millimeter wave amplifier chip testing cavity and method

A technology of chip testing and millimeter wave, which is applied in the direction of electronic circuit testing, instruments, measuring electronics, etc., can solve the problems that cannot meet the requirements of high-frequency millimeter wave amplifier chip testing, the module realizes the use of millimeter wave front-end systems, and high operating frequency, so as to reduce the The effect of small loss and simple design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

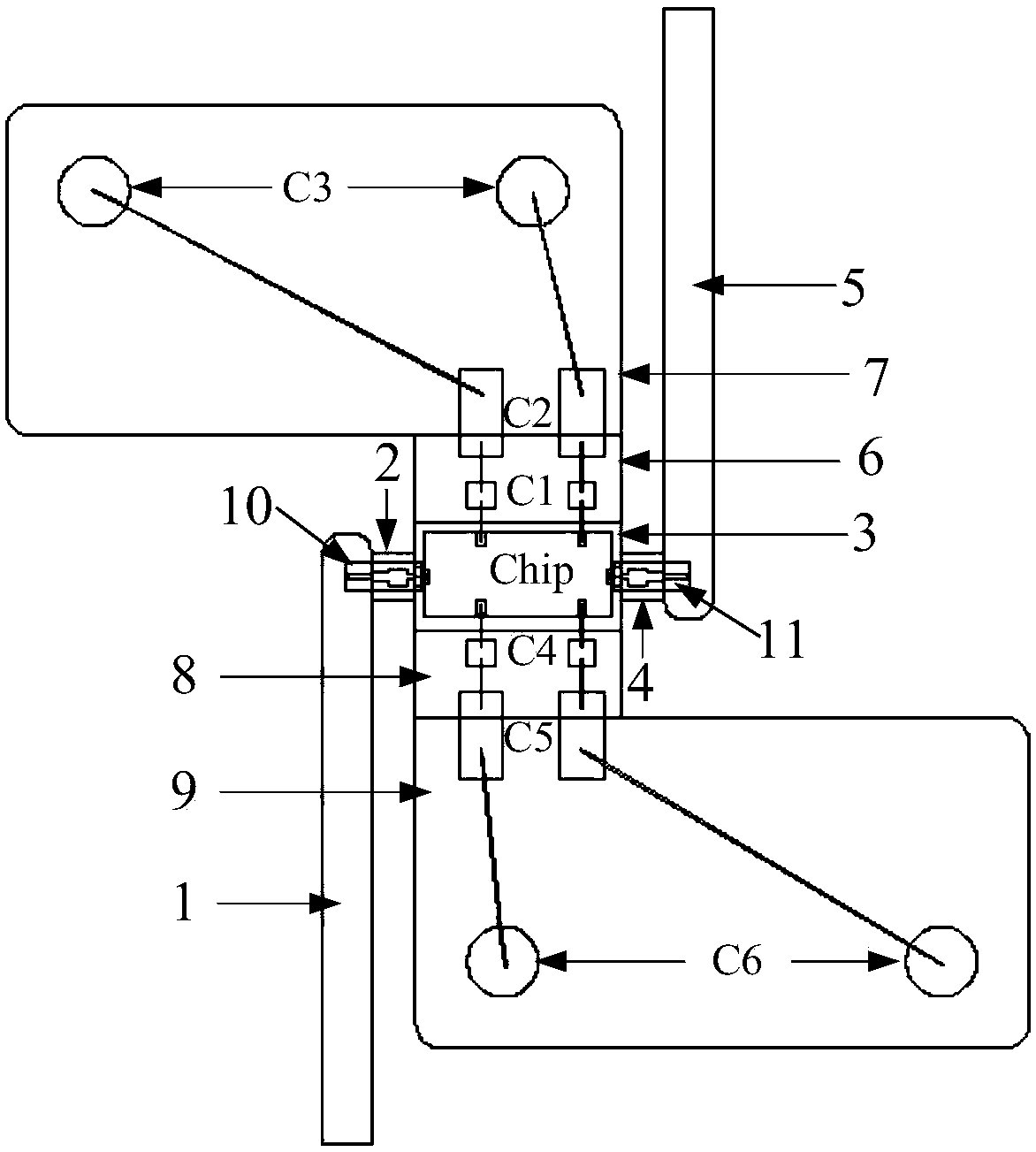

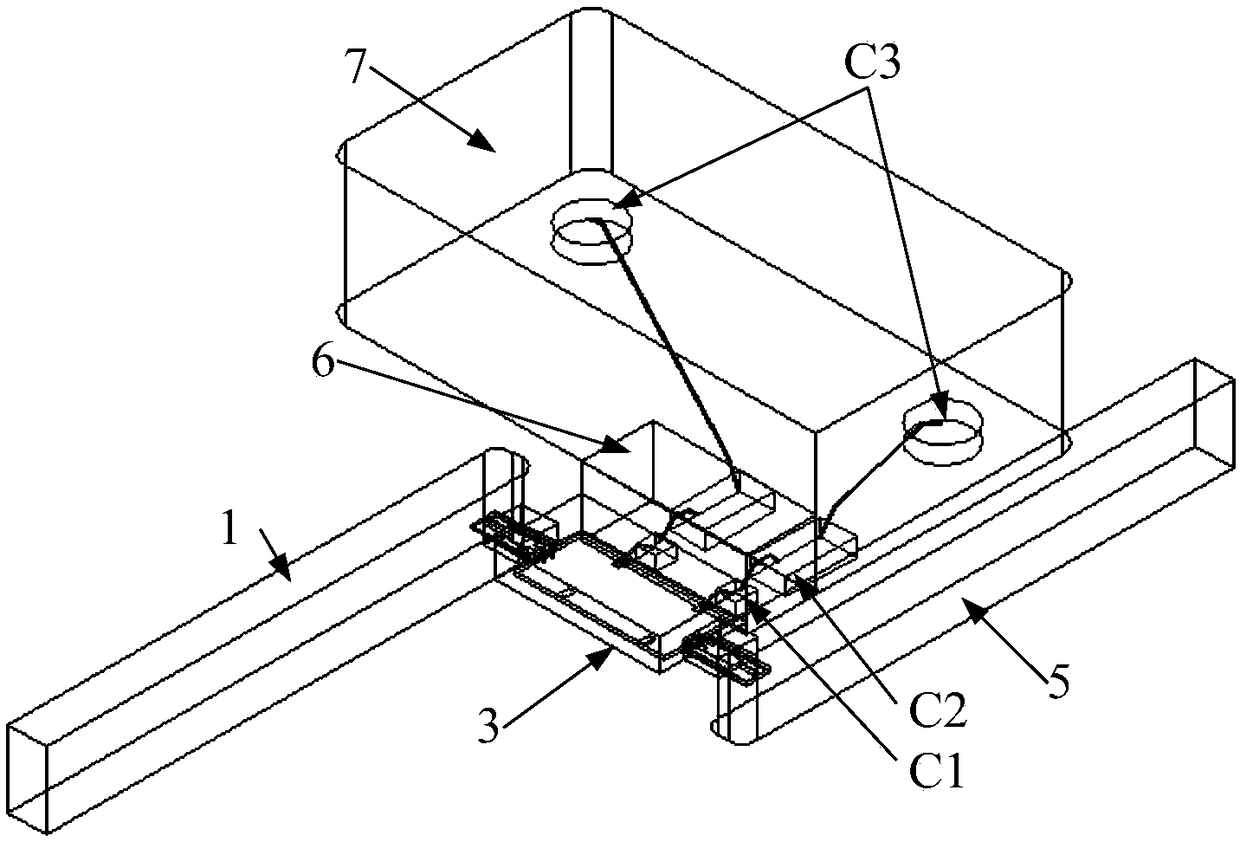

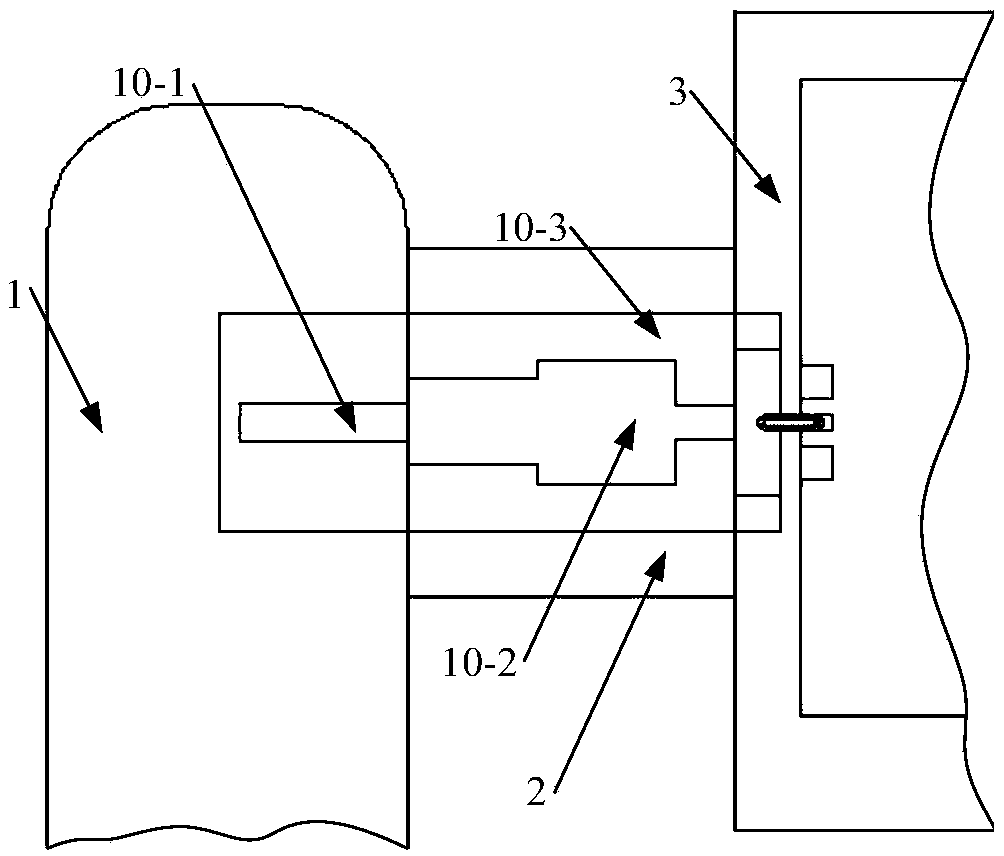

[0025] Such as figure 1 and figure 2 As shown, a millimeter-wave amplifier chip test cavity includes an input interface cavity 1, a microstrip probe matching structure loading cavity 2 at the input end, a millimeter-wave amplifier chip loading cavity 3, and a microstrip probe matching structure at the output end The loading cavity 4, the output interface cavity 5, the first capacitor combined cavity and the second capacitor combined cavity. The millimeter-wave amplifier chip test cavity is realized by computer-aided metal cavity processing technology, and is processed on brass material.

[0026] The input interface cavity 1, the input microstrip probe matching structure loading cavity 2, the millimeter wave amplifier chip loading cavity 3, the output microstrip probe matching structure loading cavity 4 and the output interface cavity 5 are connected in sequence , to rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com