Method for sliding mode servo control based on segmented permanent magnet synchronous motor

A permanent magnet synchronous motor, servo control technology, applied in the direction of motor generator control, electronic commutation motor control, control system, etc., can solve the problem of weak anti-interference ability, servo system friction, vibration, load mutation, load change adaptability Bad question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

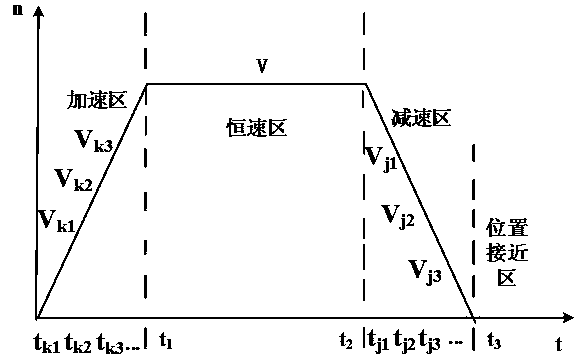

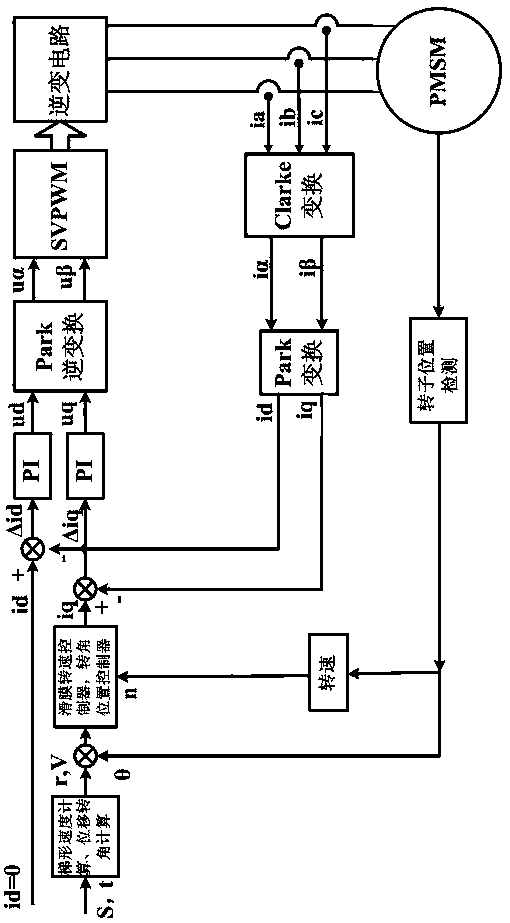

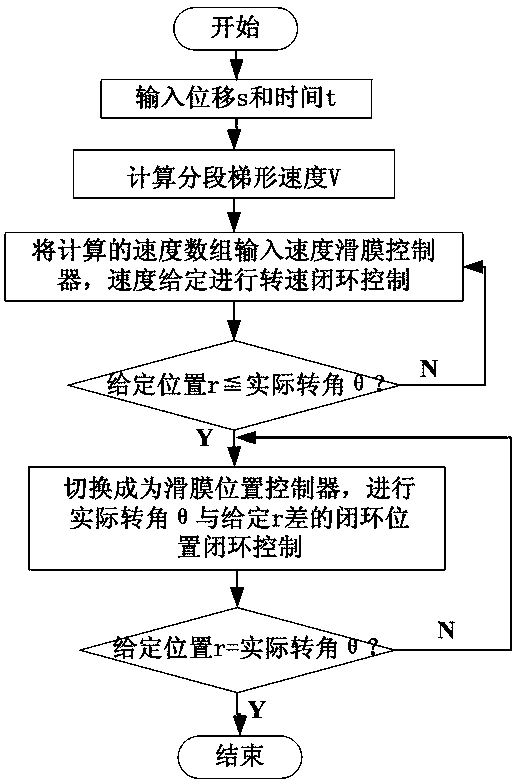

[0074] A method for sliding mode servo control based on a segmented permanent magnet synchronous motor, the method comprising the steps of:

[0075] Step 1: Establish the mathematical model of the permanent magnet synchronous motor system;

[0076] (1) Assuming that the motor magnetic field is sinusoidally distributed in space and the magnetic circuit is not saturated, without considering the hysteresis loss and eddy current loss of the iron core, through coordinate transformation, the variables in the d-q coordinate system are used to replace the variables in the A-B-C coordinate system. The self-inductance and mutual inductance coefficients of the stator winding can be changed from time-varying coefficients to constant coefficients, and the state equation of the permanent magnet synchronous motor in the d-q coordinate system can be obtained:

[0077]

[0078] In the formula: U d , U q Respectively d, q stator voltage; i d i q is d, q axis stator current; d , q R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com