Nylon polymer powder material and preparation method thereof

A technology of mixing powder materials and powder materials, which is applied in the field of additive manufacturing, can solve the problems of inability to form heat medium heat absorption and conduction and heat preservation temperature field, poor absorption effect of nylon powder, and slow heat conduction speed, so as to improve the performance of parts and prevent Effects of carbon black agglomeration and fluidity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

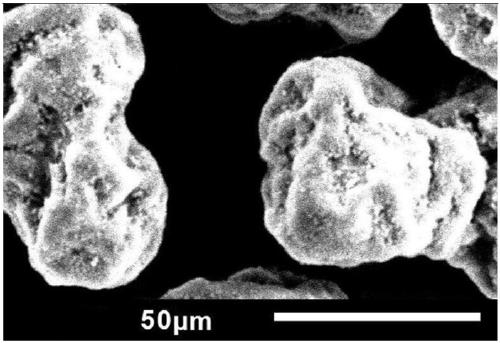

[0044] (1) Add 100 parts of nylon 1212 pellets, 1 part of carbon black with a particle size of 1 μm, and 600 parts of methanol into the polymerization kettle. The entire solvent precipitation method is divided into four stages. The first stage is the temperature increase and pressure increase stage. The stirring rate is 600r / min, the temperature is lowered to 100°C, and the pressure is reduced to 1.0Mpa; in the third stage, the heat preservation and pressure are maintained for 100min, the stirring rate is controlled at 50r / min, the heat preservation is to 100°C, and the pressure is maintained to 1.0MPa; the fourth stage, The temperature was rapidly lowered to normal temperature and pressure, and the stirring rate was 800r / min to finally obtain the nylon powder grown with the heat medium as the nucleating agent, and the particle size of the obtained nylon powder was 60 μm.

[0045] (2) Add 20 parts of nylon 1212 powder and 1 part of carbon black with a particle size of 60nm int...

Embodiment 2

[0049] (1) Add 100 parts of nylon 1010 pellets, 0.1 part of graphene with a particle size of 0.1 μm, and 700 parts of ethanol in the polymerization kettle. The entire solvent precipitation method is divided into four stages. The first stage is the temperature increase and pressure increase stage. The stirring rate is 520r / min, the temperature is lowered to 110°C, and the pressure is reduced to 1.1Mpa; in the third stage, the heat preservation and pressure are maintained for 40 minutes, the stirring rate is controlled at 70r / min, the heat preservation is 110°C, and the pressure is maintained to 1.1MPa; the fourth stage, The temperature is rapidly lowered to normal temperature and pressure, and the stirring rate is 640r / min to finally obtain a nylon powder that grows with the heat medium as a nucleating agent, and the particle size of the obtained nylon powder is 40 μm.

[0050] (2) Add 20 parts of nylon 1010 powder and 1.5 parts of carbon black with a particle size of 70nm into...

Embodiment 3

[0054] (1) Add 100 parts of nylon 6 pellets, 10 parts of ferric oxide powder with a particle size of 10 μm, and 1000 parts of dimethylformamide into the polymerization kettle. The entire solvent precipitation method is divided into four stages. The first stage is the temperature increase and pressure increase stage. The stirring rate is 570r / min, the temperature is lowered to 120°C, and the pressure is reduced to 1.2Mpa; in the third stage, the heat preservation and pressure are maintained for 70 minutes, the stirring rate is controlled to 70r / min, the heat preservation is 120°C, and the pressure is maintained to 1.2MPa; the fourth stage, The temperature is rapidly lowered to normal temperature and pressure, and the stirring rate is 700r / min to finally obtain the nylon 6 powder grown with the heat medium as the nucleating agent, and the particle size of the obtained nylon 6 powder is 50 μm.

[0055] (2) Add 20 parts of nylon 6 powder and 1 part of carbon black with a particle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com