Technology method for improving quality of burley tobacco and application of technology method

A process method and technology of burley tobacco are applied in the field of cigarette product processing to achieve the effect of simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

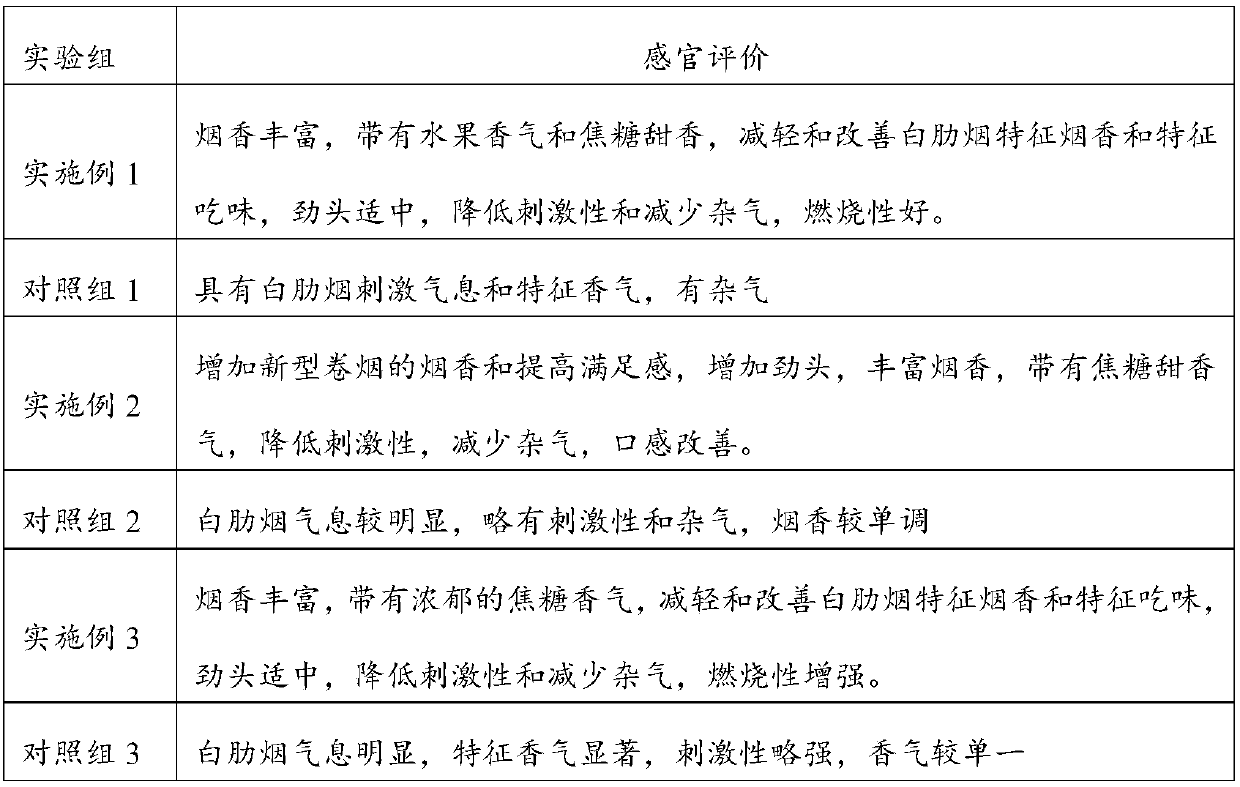

Embodiment 1

[0023] A process for improving the quality of burley tobacco, comprising the steps of:

[0024] (1) Composite hydrolysis fermentation: In the process of loosening and regaining moisture after sliced Burley tobacco, add Saccharomycopsis fibuligera and asparaginase to the aqueous solution, mix well, and spray on Burley tobacco slices to adjust the loosening and regaining moisture The machine temperature is 30°C, loosely mix the biological agent and leaves, store in the storage cabinet at 30°C for 1 day, and hydrolyze and ferment;

[0025] (2) Biological fermentation combined with Maillard reaction: transport the burley tobacco sheet in the storage cabinet of the above step (1) to the feeder, mix asparaginase and amino acid in the sugar material liquid, and adjust the pH The value is 7, evenly spraying and feeding, adjusting the temperature at 30°C to carry out enzyme hydrolysis and Maillard intermediate reaction, and then normally performing conventional procedures such as shr...

Embodiment 2

[0032] A process for improving the quality of burley tobacco, comprising the steps of:

[0033] (1) Composite hydrolysis fermentation: In the loosening and moisture regaining process after Burley tobacco slices, add Saccharomycopsis fibuligera and asparaginase to the aqueous solution, mix well, and spray on the Burley tobacco slices at a natural pH. Adjust the temperature of the loose moisture regainer to 35°C, loosely mix the biological agent and leaves, store in the storage cabinet at 35°C for 2 days, and hydrolyze and ferment;

[0034] (2) Biological fermentation combined with Maillard reaction: the burley tobacco sheet in the storage cabinet of the above step (1) is transported to the feeder, and the asparaginase and amino acid are mixed in the sugar material liquid to adjust the pH value 8, evenly spray and feed, adjust the temperature at 35°C to carry out enzymatic hydrolysis and Maillard intermediate reaction, and then normally perform conventional procedures such as sh...

Embodiment 3

[0041] A process for improving the quality of burley tobacco, comprising the steps of:

[0042] (1) Composite hydrolysis fermentation: In the process of loosening and regaining moisture after burley tobacco slices, add Saccharomycopsis fibuligera and asparaginase to the aqueous solution and mix well, the pH is natural, and adjust the temperature of the loosening and dampening machine to 40°C , loosely mix biological preparations and leaves, store in a storage cabinet at 37°C for 3 days, hydrolyze and ferment;

[0043] (2) Biological fermentation combined with Maillard reaction: the burley tobacco sheet in the storage cabinet of the above step (1) is transported to the feeder, and the asparaginase and amino acid are mixed in the sugar material liquid to adjust the pH value 9, evenly spray and feed, adjust the temperature at 40°C to carry out enzyme hydrolysis and Maillard intermediate reaction, and then normally perform conventional procedures such as shredding and drying to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com