A microneedle transdermal drug delivery patch for treating rheumatoid arthritis and its preparation method

A rheumatoid, transdermal drug delivery technology, applied in the direction of microneedles, pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve the problems of toxic and side effects of patients, reduce the efficacy of drugs, and difficult for patients to accept, so as to avoid side effects, The effect of avoiding irritation and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

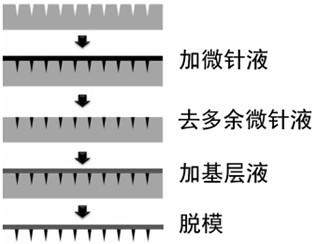

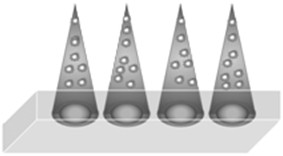

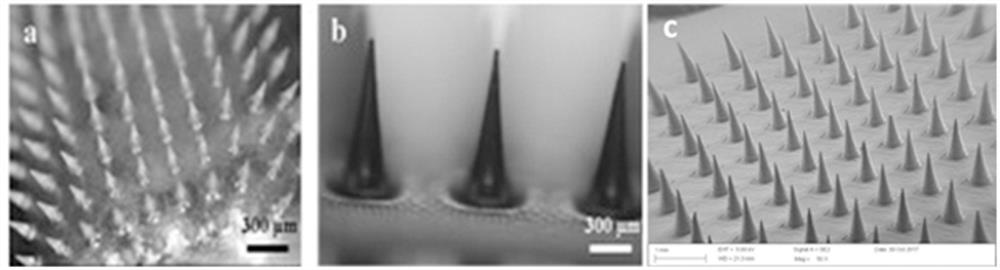

[0046] A microneedle transdermal drug delivery patch for treating rheumatoid arthritis with a cuboid shape of 1 cm × 1 cm × 0.2 cm in the base layer and a conical microneedle was prepared, the number of microneedles was 100, the length of the microneedles was 800 microns and Regular arrangement of needle intervals:

[0047] (1) Mold preparation: CNC micro-milling technology is used to prepare the male mold, and then the male mold is used to replicate the female mold; the male mold is made of brass; the material of the female mold is polydimethylsiloxane (PDMS). There are interconnected microneedle chambers and base chambers in the female mold. The base chamber is a cuboid cavity with a length and width of 1 cm and a height of 0.2 cm. The 100 microneedle cavities are all conical cavities. The diameter of the bottom of the cavity is 100 microns, and the height is 800 microns, and each microneedle cavity is perpendicular to the base cavity and arranged evenly with each other;

...

Embodiment 2

[0056] A microneedle transdermal drug delivery patch for treating rheumatoid arthritis with a cuboid shape of 1 cm × 1 cm × 0.2 cm in the base layer and a conical microneedle was prepared, the number of microneedles was 100, the length of the microneedles was 800 microns and Regular arrangement of needle intervals:

[0057] (1) Mold preparation: CNC micro-milling technology is used to prepare the male mold, and then the male mold is used to replicate the female mold; the male mold is made of aluminum; the female mold is made of polydimethylsiloxane (PDMS). There are interconnected microneedle chambers and base chambers in the female mold. The base chamber is a cuboid cavity with a length and width of 1 cm and a height of 0.2 cm. The 100 microneedle cavities are all conical cavities. The diameter of the bottom of the cavity is 100 microns, and the height is 800 microns, and each microneedle cavity is perpendicular to the base cavity and arranged evenly with each other;

[0058...

Embodiment 3

[0063] Prepare a microneedle transdermal patch for the treatment of rheumatoid arthritis with a diameter of 1 cm, a height of 0.2 cm, and a microneedle transdermal patch for the treatment of rheumatoid arthritis with microneedles in the shape of a flat cylinder with a diameter of 1 cm and a height of 0.2 cm. The number of microneedles is 80, and the length of the microneedles is 1000 microns and regular arrangement of microneedles:

[0064] (1) The male mold is prepared by CNC micro-milling technology, and then the female mold is copied by the male mold; the male mold is made of aluminum alloy; the material of the female mold is polydimethylsiloxane (PDMS). There are interconnected microneedle chambers and base chambers in the female mold. The base chamber is a flat cylindrical cavity with a bottom diameter of 1 cm and a height of 0.2 cm. The 80 microneedle cavities are all quadrangular pyramid-shaped cavities. The bottom side length of the shaped cavity is 100 microns, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com