Organic waste gas treatment system

A treatment system and organic waste gas technology, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems of secondary pollution, increase the cost of solid waste and hazardous waste treatment, waste of resources, etc., and achieve the effect of efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

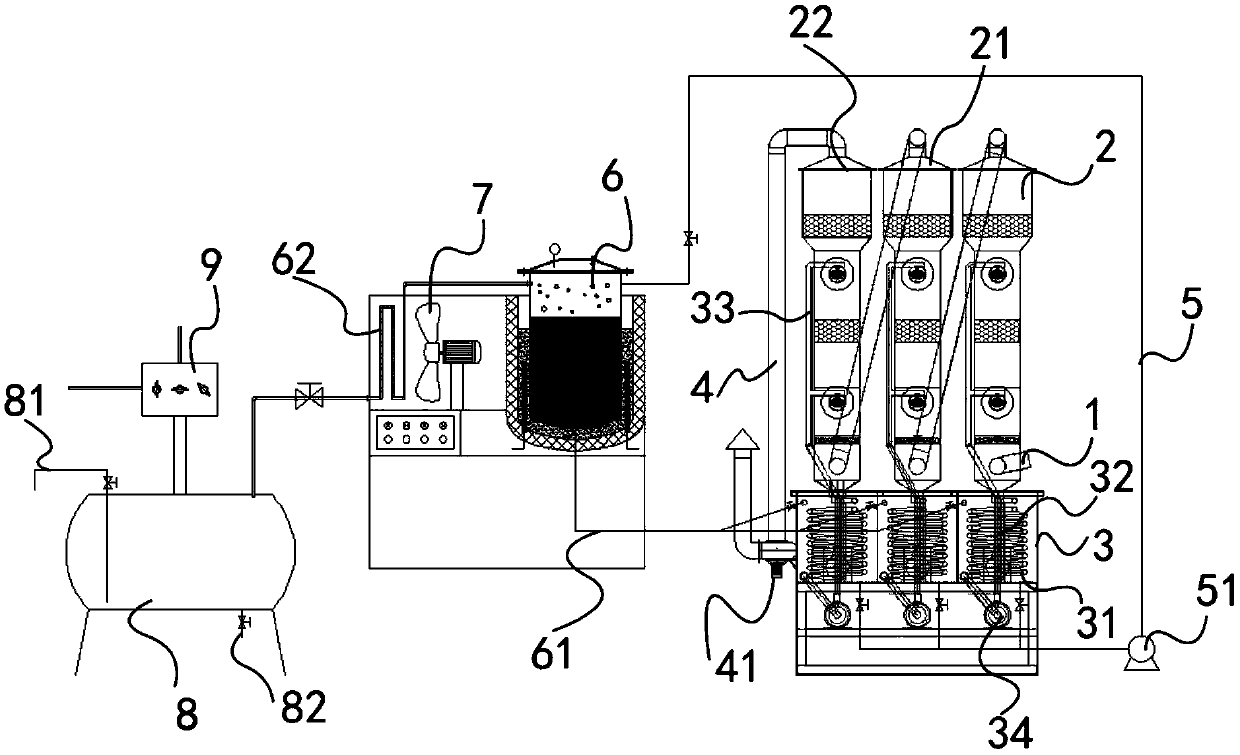

[0021] An embodiment of the organic waste gas treatment system of the present invention, such as figure 1 As shown, it comprises a spraying device and a vacuum distillation device, and the spraying device comprises the first spray tower 2, the second spray tower 21 and the third spray tower 22 connected in sequence, the inlet of the first spray tower 2 Air intake pipe 1 is installed on the gas end, exhaust pipe 4 is connected to the exhaust end of the third spray tower 22, exhaust fan 41 is installed on the exhaust pipe 4, the first spray tower 2, the second spray tower 21 and the liquid discharge end of the third spray tower 22 are all connected to the liquid storage tank 3, and the first spray tower 2, the second spray tower 21 and the third spray tower 22 all include the spray pipe 33 that the shower head is installed, and the spray The shower pipe 33 is sequentially connected with a liquid inlet pipe 32, a liquid inlet pump 34 is installed on the liquid pipe 32, a liquid s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap