Mg-Fe bimetal hydroxide adsorbent and preparation method and application thereof

A hydroxide and adsorbent technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of slow adsorption rate, uranium adsorption, poor adsorption effect, etc., and achieve the adsorption rate Fast, large adsorption capacity, effective adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

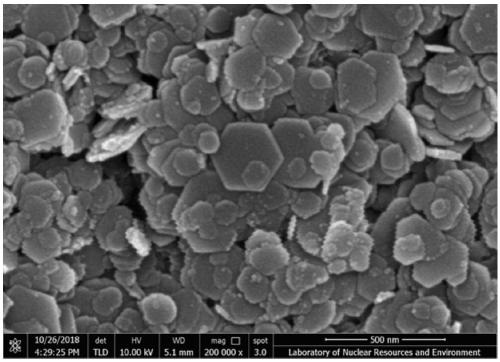

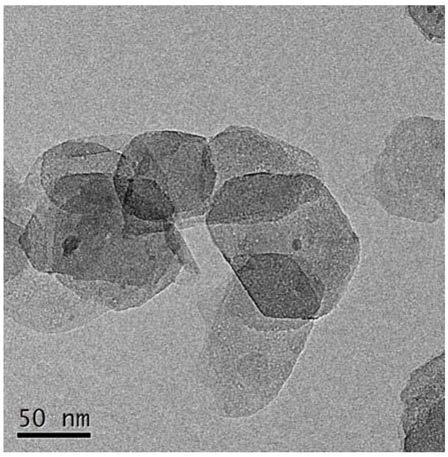

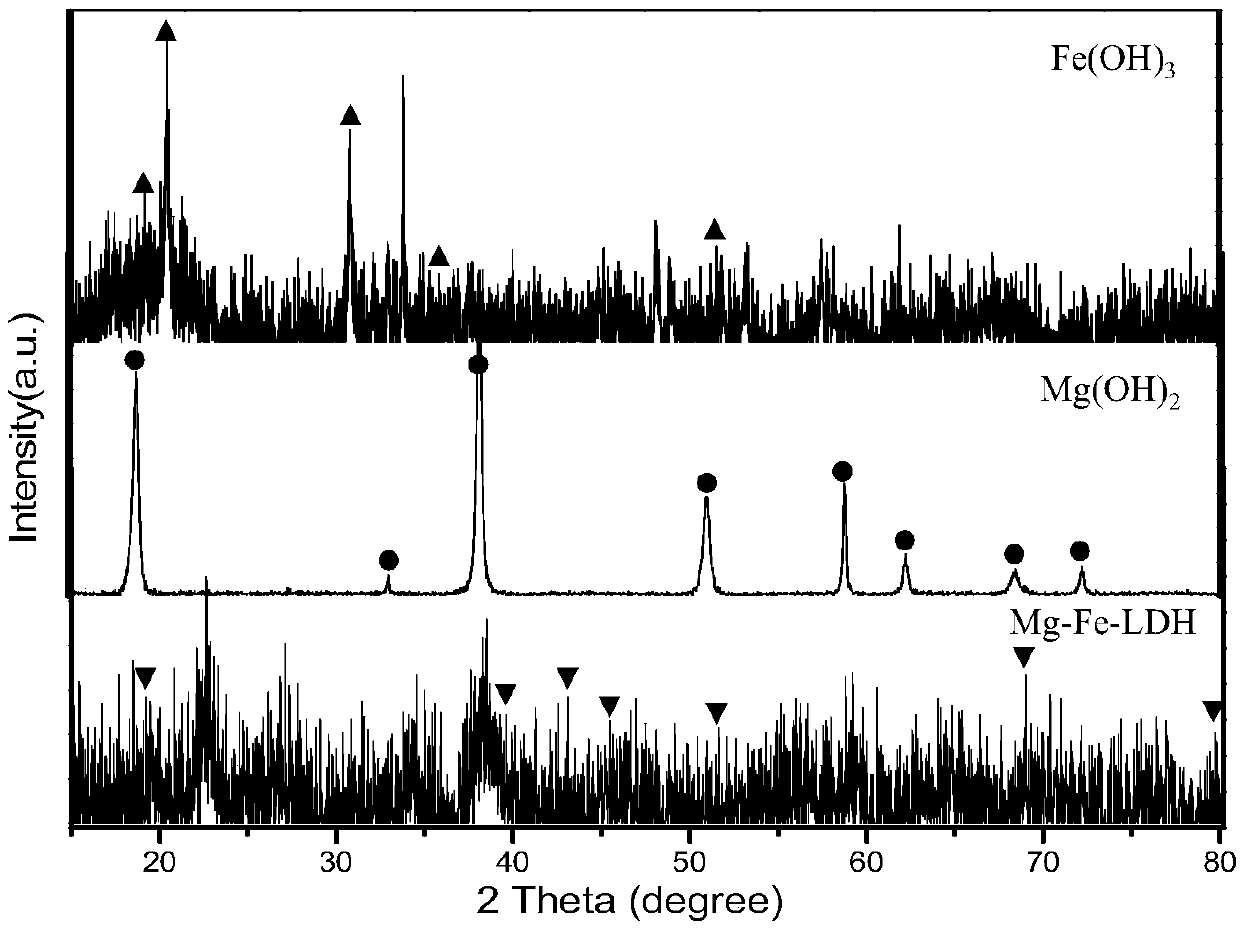

[0030] The embodiment of the present invention also provides a method for preparing a Mg-Fe double metal hydroxide adsorbent, which includes: performing a hydrothermal reaction with the iron-magnesium mixed solution formed after mixing the iron salt and the magnesium salt, and the hydroxide solution, and Centrifuge. Magnesium ions and iron ions form Mg-Fe double-layer hydroxide under alkaline hydrothermal conditions, so that magnesium hydroxide spreads on the surface of iron hydroxide, so that the physical defects and chemical active sites of magnesium hydroxide are fully exposed. To promote the adsorption of uranyl ions in wastewater.

[0031] Specifically, the iron salt is selected from any one of ferric chloride, ferric nitrate and ferric sulfate, preferably ferric chloride, more preferably ferric chloride hexahydrate; similarly, the magnesium salt is selected from magnesium chloride, magnesium nitrate and magnesium sulfate Any one of them is preferably magnesium chloride,...

Embodiment 1

[0041] The present embodiment provides a kind of preparation method of Mg-Fe double metal hydroxide adsorbent, it comprises the following steps:

[0042] Dissolve ferric nitrate and magnesium nitrate in deionized water to obtain a mixed solution of iron and magnesium, wherein the molar ratio of Mg / Fe is 3:1, and the total concentration of magnesium ions and iron ions in the mixed solution of iron and magnesium is 0.07mol / L. Pour the iron-magnesium mixture into the hydrothermal reaction liner, and add 0.5 mol / L NaOH solution (total amount is excess relative to the molar amounts of iron ions and magnesium ions), so that the pH of the system is 10. Put the lining into the autoclave for 100 minutes under the conditions of 160°C and 5.5Mpa. After the reaction was completed, it was taken out, centrifuged and washed until the supernatant was neutral, and the obtained solid was freeze-dried at -40°C for 10 hours and dried for later use.

[0043] This embodiment also provides a treatm...

Embodiment 2

[0045] The present embodiment provides a kind of preparation method of Mg-Fe double metal hydroxide adsorbent, it comprises the following steps:

[0046] Dissolve ferric chloride hexahydrate and magnesium chloride hexahydrate in deionized water to obtain a mixed solution of iron and magnesium, wherein the molar ratio of Mg / Fe is 5:1, and the total concentration of magnesium ions and iron ions in the mixed solution of iron and magnesium is 0.012mol / L . Pour the iron-magnesium mixture into the hydrothermal reaction lining, and add 1.5 mol / L NaOH solution (the total amount is excessive relative to the molar amounts of iron ions and magnesium ions), so that the pH of the system is 13. Put the lining into the autoclave for 150min under the conditions of 200°C and 6.5Mpa. After the reaction was completed, it was taken out, centrifuged and washed until the supernatant was neutral, and the obtained solid was freeze-dried at -60°C for 14 hours and dried for later use.

[0047] This e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com