Production method of granular cold-water-soluble starch

A production method and soluble technology are applied in the production field of granular cold water soluble starch, which can solve the problems of industrial waste water generation, insufficient environmental protection, high cost and the like, and achieve the effects of less waste water, easy operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

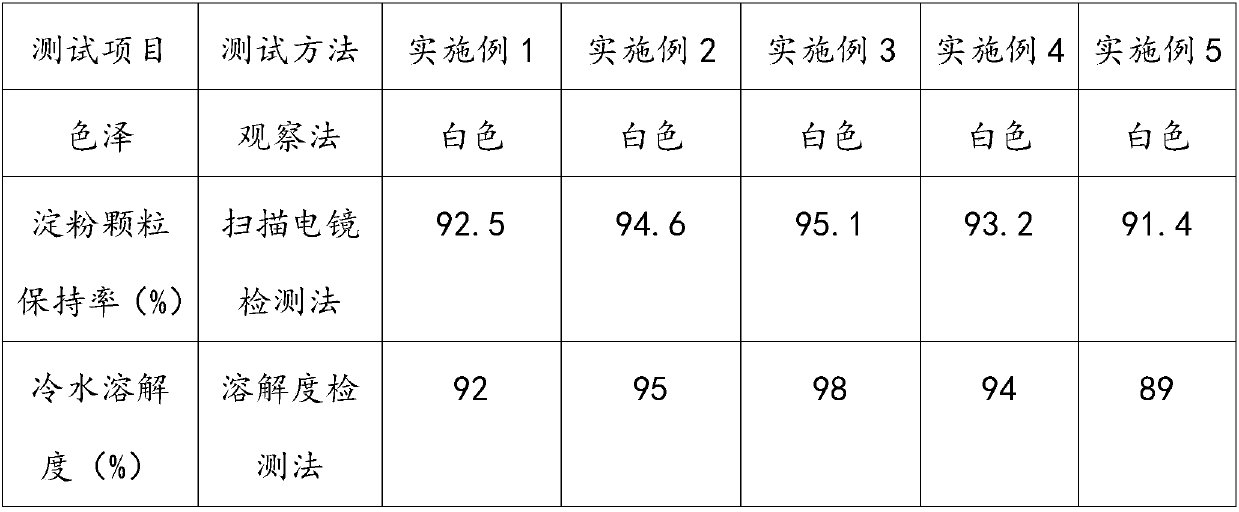

Examples

Embodiment 1

[0031] A production method of granular cold water soluble starch, comprising the following steps:

[0032] (1) Acidification

[0033] Get 100g edible grade cornstarch and add in the mixer, then mist-spray into 1000ml of hydrochloric acid with a mass concentration of 10% and mix for 5min to prepare acidified cornstarch;

[0034] (2) fermentation

[0035] Put the acidified cornstarch prepared above into a container or a starch bag and ferment at 25°C for 7 hours to obtain fermented cornstarch;

[0036] (3) washing

[0037] The fermented cornstarch was washed twice with ethanol with a mass concentration of 85% in the washing tank for sedimentation, and then neutralized by adding sodium hydroxide solution until the pH value was 5.0 to obtain modified cornstarch;

[0038] (4) centrifugation and drying

[0039] The modified cornstarch prepared above is placed in a centrifuge and centrifuged at a centrifugal speed of 800r / min for 60min, then placed in a dryer at 100°C for flash d...

Embodiment 2

[0042] A production method of granular cold water soluble starch, comprising the following steps:

[0043] (1) Acidification

[0044] Get 100g of food grade wheat starch and add it into the mixer, then spray it into 900ml of hydrochloric acid with a mass concentration of 10% and mix for 5.5min to prepare acidified wheat starch;

[0045] (2) fermentation

[0046] Put the acidified wheat starch prepared above into a container or a starch bag and ferment at 26° C. for 7 hours to obtain fermented wheat starch;

[0047] (3) washing

[0048] Washing the fermented wheat starch in a washing tank twice with ethanol with a mass concentration of 85% for sedimentation, and then adding potassium hydroxide solution to neutralize until the pH value is 5.5 to obtain modified wheat starch;

[0049] (4) centrifugation and drying

[0050] The modified wheat starch prepared above is placed in a centrifuge and centrifuged at a centrifugal speed of 850r / min for 50min, then placed in a dryer at 10...

Embodiment 3

[0053] A production method of granular cold water soluble starch, comprising the following steps:

[0054] (1) Acidification

[0055] Get 100g of food grade mung bean starch and add it into the mixer, then spray it into 800ml of hydrochloric acid with a mass concentration of 10.5% and mix for 5.5min to obtain acidified mung bean starch;

[0056] (2) fermentation

[0057] Put the acidified mung bean starch prepared above into a container or a starch bag and ferment for 6.5 hours at 27°C to obtain fermented mung bean starch;

[0058] (3) washing

[0059] Washing the fermented mung bean starch with ethanol with a mass concentration of 85% in the washing tank for 3 times for sedimentation, and then adding sodium bicarbonate solution to neutralize to a pH value of 6 to obtain modified mung bean starch;

[0060] (4) centrifugation and drying

[0061] The modified mung bean starch prepared above is placed in a centrifuge and centrifuged at a centrifugal speed of 900r / min for 40mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com