Moisture power generation method and device

A power generation device and moisture technology, which is applied in the direction of generators/motors, generators that convert kinetic energy into electric energy, electrical components, etc., can solve the problems of cumbersome manufacturing process and high price, and achieve good device performance recovery, good humidity Effect of moisture control, good moisture self-healing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] (a) if image 3 As shown, the 1788 type polyvinyl alcohol (PVA) is made into an aqueous solution of 10% solid content, and the poly(4-styrenesulfonic acid) (PSSA) with a molecular weight of 75000 is 30% with a solid content according to a volume ratio of 1: 1 was mixed to obtain a solution with a total volume of 5 mL. Pour it into a plastic petri dish with a diameter of 6 mm, then put it in an oven, set the temperature of the oven at 45°C, and dry it with air for 3 hours to obtain a polymer power generation film, which shows good flexibility and the obtained power generation film membrane.

[0060] (b) if Figure 4 As shown, the polymer power generation membrane obtained above has a smooth surface and a compact internal structure.

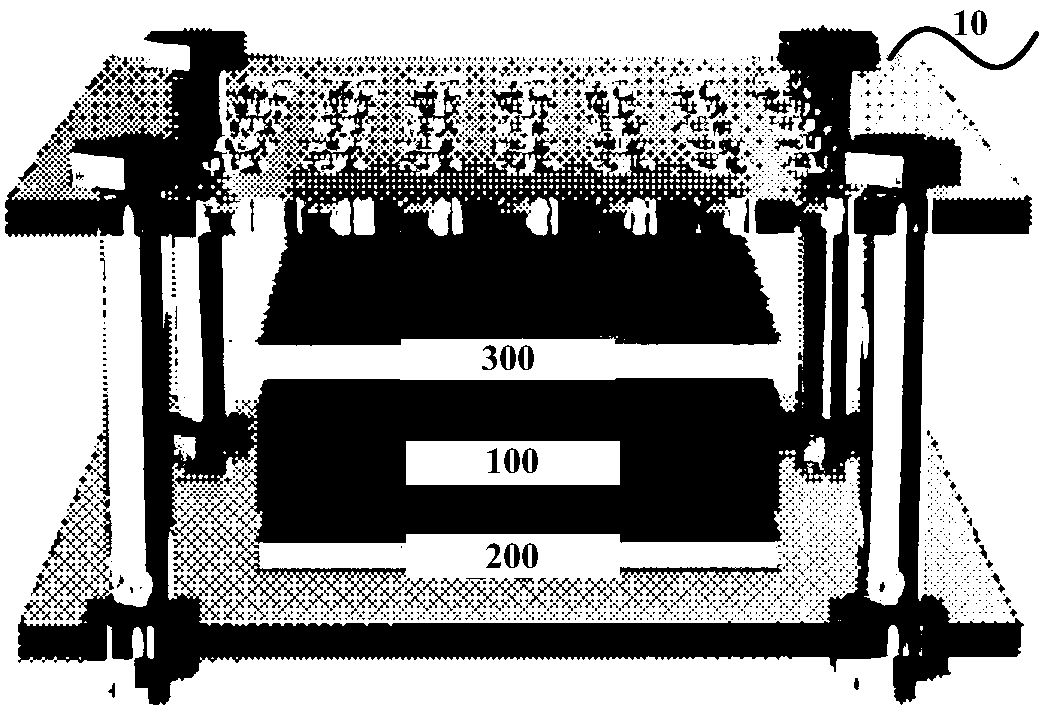

[0061] (c) Prepare the top electrode of the moisture power generation device: take a metal silver electrode sheet with a thickness of 0.2 mm and a size of 1 × 1 cm, and then use a laser to drill holes with a diameter of 20 × 20 microns, a...

Embodiment 2

[0067] In the embodiment of the present invention, the polymer power generation membrane and the moisture power generation device were prepared according to the same method as in the embodiment 1. The difference is: (a) the poly(4-styrenesulfonic acid) (PSSA) solution with a solid content of 30% and a molecular weight of 75,000 was taken, and the film was prepared by subsequent drying; (c) the top electrode was a porous gold electrode, the size of 2 x 2 cm;

[0068] In this embodiment of the present invention, when the relative humidity changes by 90%, the polymer power generation film can generate a voltage up to 0.8V and a current of 200μA.

Embodiment 3

[0070] In this embodiment of the present invention, the polymer power generation membrane and the moisture power generation device were prepared by basically the same method as in embodiment 1. The difference is: (a) take 5mL of 10% solid content and dry 1788 type polyvinyl alcohol (PVA) to obtain a film;

[0071] In this embodiment of the present invention, when the relative humidity changes by 30%, the polymer power generation film can generate a voltage as high as 0.3V and a current as high as 0.2μA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com