Bismuth germanate two-dimension nanosheet and preparing method thereof

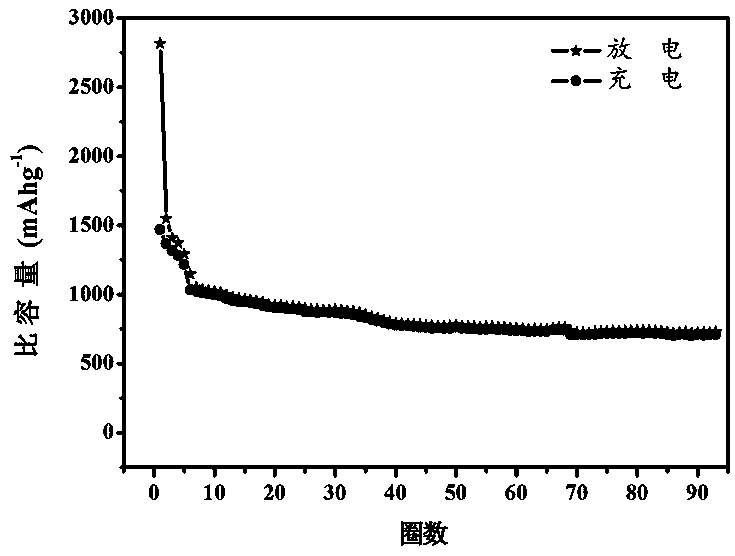

A two-dimensional nano, bismuth germanate technology, applied in nanotechnology, chemical instruments and methods, bismuth compounds, etc., can solve the problems of low graphite capacity and achieve the effect of high charge and discharge capacity and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

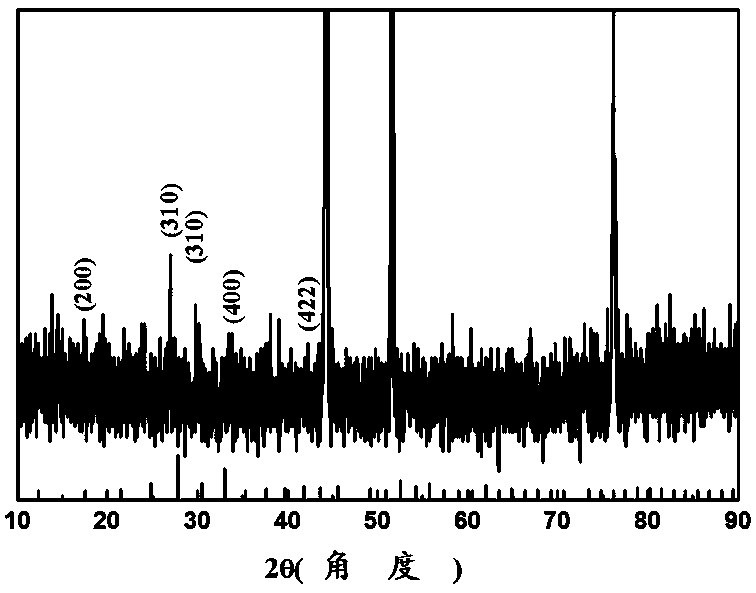

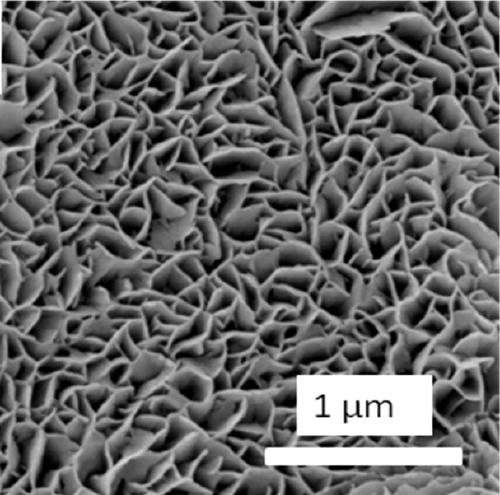

[0024] A bismuth germanate two-dimensional nanosheet, the shape of the bismuth germanate is a two-dimensional nanosheet structure, and its thickness is 3 to 50 nm. Its diameter is approximately 200-500 nm, and the diameter here does not only refer to the size when the two-dimensional nanosheet structure is circular, but also refers to the approximate size when it is non-circular, which are well known to those skilled in the art .

[0025] The two-dimensional bismuth germanate nanosheet is prepared by a solvothermal method using bismuth triiodide and germanium dioxide as raw materials, a mixture of ethylene glycol and water as a solvent, and nickel foam as a substrate.

[0026] The ratio of the amount of bismuth triiodide and germanium dioxide is (0.3~2): 1, the total amount of bismuth triiodide and germanium dioxide added is 1~4 mmol, and the amount of ethylene glycol is 5 ~ 25 mL, the amount of water used is 5 ~ 25 mL.

[0027] The present invention also provides a method f...

Embodiment 2

[0040] A bismuth germanate two-dimensional nanosheet, the shape of the bismuth germanate is a two-dimensional nanosheet structure, and the thickness of the sheet structure is 30nm. The diameter of the sheet is 200 ~ 300 nm.

[0041] The two-dimensional bismuth germanate nanosheet is prepared by a solvothermal method using bismuth triiodide and germanium dioxide as raw materials, a mixture of ethylene glycol and water as a solvent, and nickel foam as a substrate.

[0042] The ratio of the amount of substance of described bismuth triiodide and germanium dioxide is 1:1, the total addition amount of bismuth triiodide and germanium dioxide is 1.5mmol, the consumption of ethylene glycol is 10 mL, and the consumption of water is 20 mL.

[0043] The preparation method of the above-mentioned two-dimensional bismuth germanate nanosheets consists of the following steps:

[0044] (1) First, dissolve 1.5 mmol of bismuth triiodide and germanium dioxide in a mixed solution of 10 mL of ethy...

Embodiment 3

[0053] The difference with embodiment 2 is:

[0054] The present embodiment bismuth germanate Bi 4 Ge 3 o 12 The preparation method of two-dimensional nanosheets consists of the following steps:

[0055] (1) First, dissolve 1 mmol of bismuth triiodide and germanium dioxide in a mixed solution of 20 mL of ethylene glycol and 10 mL of water, and obtain a mixed solution after magnetic stirring for 2 hours; the amount of bismuth triiodide and germanium dioxide The ratio is 1.3:1;

[0056] (2) Add the above mixture to 1 mL of N,N'-diisopropylcarbodiimide dropwise, and keep stirring for 3 hours to obtain a solution;

[0057] (3) Put the solution in step (2) into a hydrothermal reaction kettle for hydrothermal reaction. A piece of nickel foam substrate is placed inside the hydrothermal reaction kettle. The hydrothermal reaction time is 18 hours and the temperature is 210 ℃; The capacity of the hydrothermal reaction kettle is 50ml, and other capacities are also available;

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com