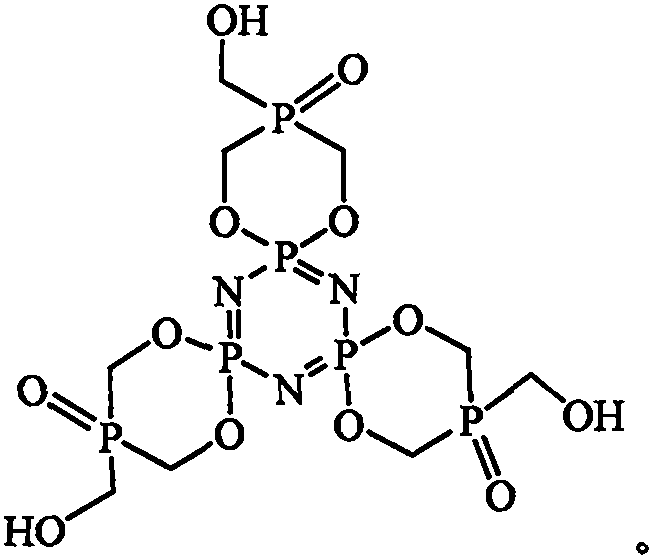

Flame retardant namely trimeric O,O-2-hydroxymethylphosphonyl heteropropylene phosphazene compound and preparation method thereof

A technology of hydroxymethylphosphonoheterylene phosphazene and trimethylolphosphorus oxide is applied in the field of flame retardant trimer O, which can solve the problems such as the limitation of halogen-based flame retardants, and achieve high flame retardant efficiency and structure. Novel and symmetrical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

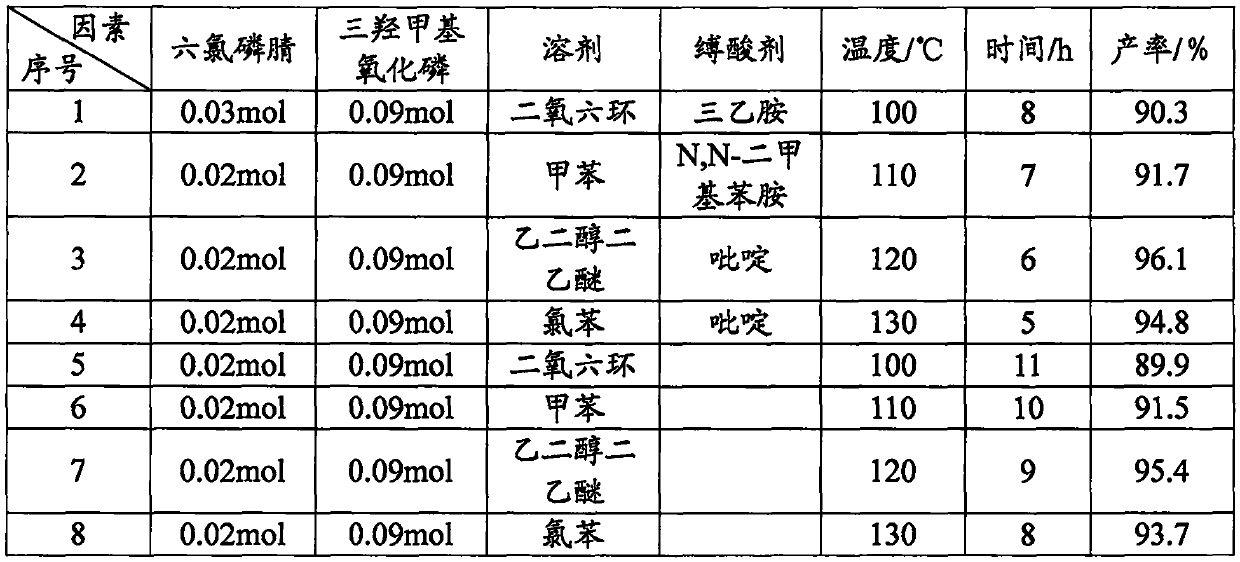

Embodiment 1

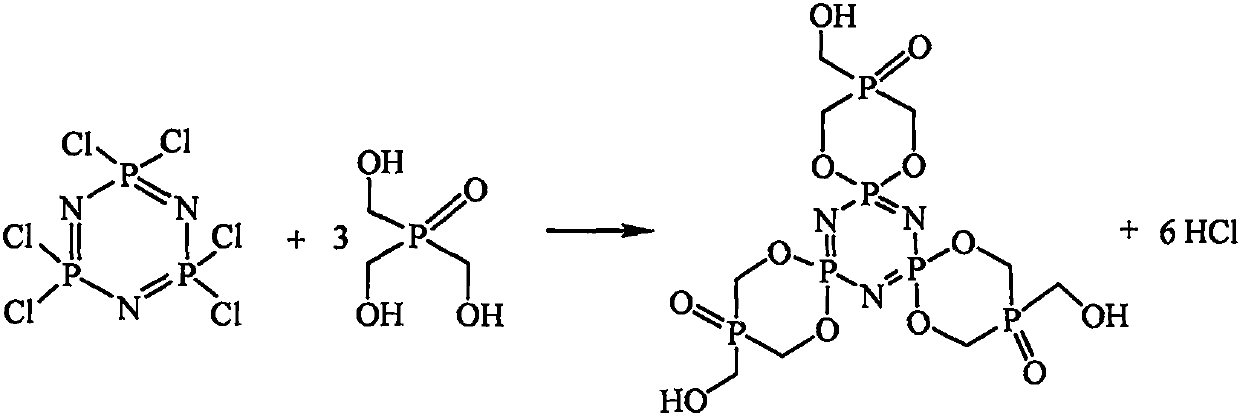

[0024] Example 1 In a 250ml three-necked flask equipped with a stirrer, a thermometer and a condenser tube, and a drying tube at the top of the condenser tube, replace the air in the bottle with nitrogen, and add 10.42g (0.03mol) of hexachlorocyclotri Phosphazene, 80ml dioxane and 18.18g (0.18mol) triethylamine, after stirring to dissolve hexachlorocyclotriphosphazene, add 12.61g (0.09mol) trimethylol phosphorus oxide dropwise, and control the reaction with the dropping rate The temperature is not higher than 40°C. After dropping, the temperature is raised to 100°C, and the temperature is kept for 8 hours; the temperature is lowered to below 30°C, and the formed triethylamine hydrochloride is removed by suction filtration, and dioxane is removed by vacuum distillation (recycling). Add 35ml of distilled water to wash twice, separate the lower organic phase, add 35ml of ethyl acetate, dry with 1g of anhydrous magnesium sulfate, filter with suction, distill the filtrate under redu...

Embodiment 2

[0025] Example 2 In a 250ml three-necked flask equipped with a stirrer, a thermometer and a condenser tube, and a drying tube at the top of the condenser tube, replace the air in the bottle with nitrogen, and add 10.42g (0.03mol) of hexachlorocyclotri Phosphazene, 80ml toluene and 21.78g (0.18mol) N, N-dimethylaniline, after stirring to dissolve hexachlorocyclotriphosphazene, add 12.61g (0.09mol) trihydroxymethyl phosphorus oxide dropwise, at the rate of addition Control the reaction temperature not to be higher than 40°C, raise the temperature to 110°C after dripping, and keep the temperature for 7 hours; lower the temperature to below 30°C, remove the generated N,N-dimethylaniline hydrochloride by suction filtration, and remove the toluene ( Recycling), add 35ml of distilled water to wash twice, separate the lower organic phase, add 35ml of ethyl acetate, dry with 1g of anhydrous magnesium sulfate, filter with suction, and distill the filtrate under reduced pressure to remove...

Embodiment 3

[0026] Example 3 In a 250ml three-neck flask equipped with a stirrer, a thermometer and a condenser tube, and a drying tube at the top of the condenser tube, replace the air in the bottle with nitrogen, and add 10.42g (0.03mol) of hexachlorocyclotri Phosphazene, 80ml ethylene glycol diethyl ether and 14.22g (0.18mol) pyridine, after stirring to dissolve hexachlorocyclotriphosphazene, add 12.61g (0.09mol) trimethylol phosphorus oxide dropwise, and control the reaction temperature with the dropping rate Not higher than 40°C, after dripping, raise the temperature to 120°C, keep the temperature for 6 hours; cool down to below 30°C, remove the generated pyridine hydrochloride by suction filtration, remove ethylene glycol diethyl ether (recycling) by vacuum distillation, add Wash twice with 35ml of distilled water, separate the lower organic phase, add 35ml of ethyl acetate, dry with 1g of anhydrous magnesium sulfate, filter with suction, distill the filtrate under reduced pressure t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com