Method for improving yield and purity of methane in microbial electrolytic cell

A microbial electrolysis cell and production technology, which is applied in the direction of electrolysis organic production, electrolysis process, electrolysis components, etc., can solve the problems affecting the direct utilization of biogas, low degradation rate of organic matter, increase economic cost, etc. The effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

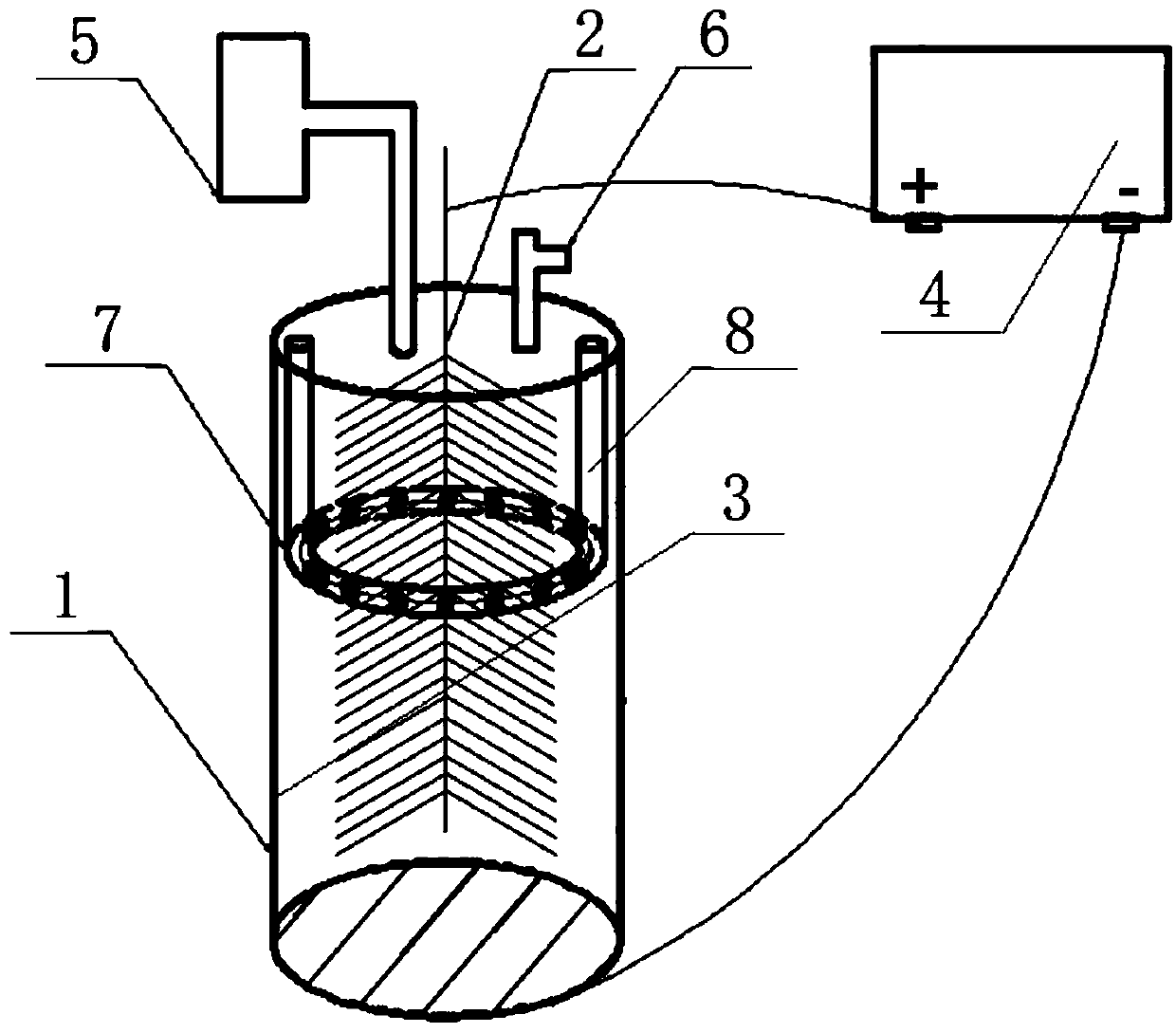

[0042] In this embodiment, wollastonite is placed on the support 7 of the microbial electrolytic cell reactor, and the specific steps are as follows:

[0043] Microbial electrolytic cell reactors in which the effluent microorganisms of the secondary sedimentation tank of a sewage treatment plant are used as inoculum to domesticate and cultivate electrode biofilms. The anode uses a carbon fiber brush with a diameter of about 5 cm, and the cathode uses a carbon fiber cloth coated with a platinum-carbon alloy catalyst (platinum-loaded area About 0.5mg / cm 2 ), the reactor capacity is 500mL, 420mL sludge hydrolyzate is added into the reactor, 8g (the dosage of wollastonite powder is 19.05g / L) wollastonite powder with a particle size of 100µm is wrapped in a 3500Da dialysis bag, and placed On the bracket 7, the distance between the dialysis bag and the bristles on the outermost edge of the anode carbon brush is 0.5cm, the applied voltage is 0.8V, and the initial pH is 7.0. Stir and ...

Embodiment 2

[0045] Embodiment 2, embodiment 3, the technique of embodiment 4 are identical with embodiment 1, and difference is, do not add wollastonite powder in the dialysis bag in embodiment 2, and the wollastonite powder in the dialysis bag in embodiment 3 is 5g (throwing The dosage is 11.95mg / L), and the wollastonite powder in the dialysis bag in Example 4 is 10g (the dosage is 23.81g / L).

Embodiment 5

[0047] The difference between this example and Example 1 is that in this example, 8g of wollastonite powder is packed into a dialysis bag and placed in the reactor without being fixed by a bracket 7, and other conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com