A Radial Displacement Measuring Device for Small Aperture Tunnel Model Test

A technology of radial displacement and model testing, applied in the direction of measuring devices, elastic testing, machine/structural parts testing, etc., can solve the problems of lack of measuring devices, excessive deformation of unsuitable small holes, and distortion of measurement results, etc., to achieve Strong scene adaptability, convenient and fast measurement, and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

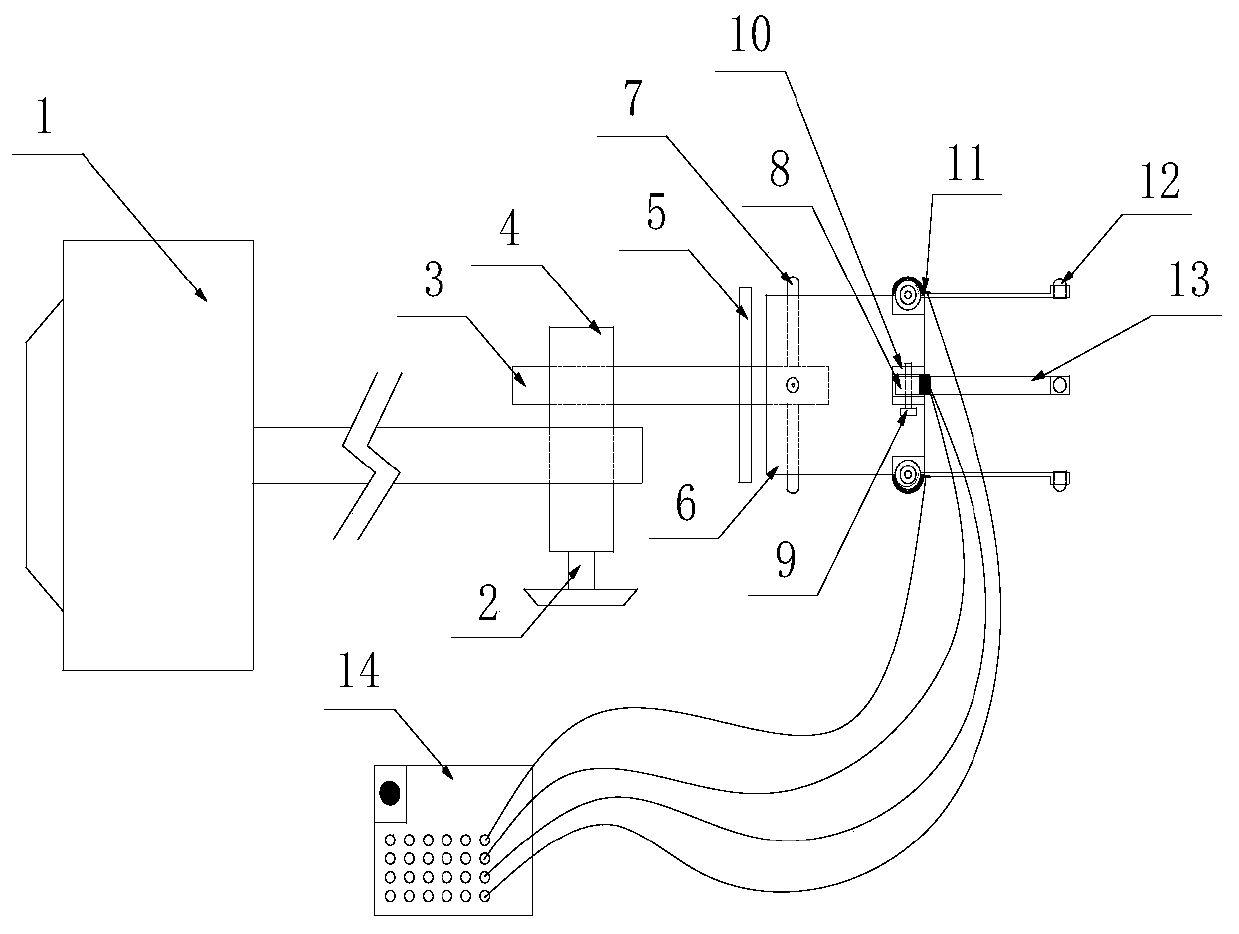

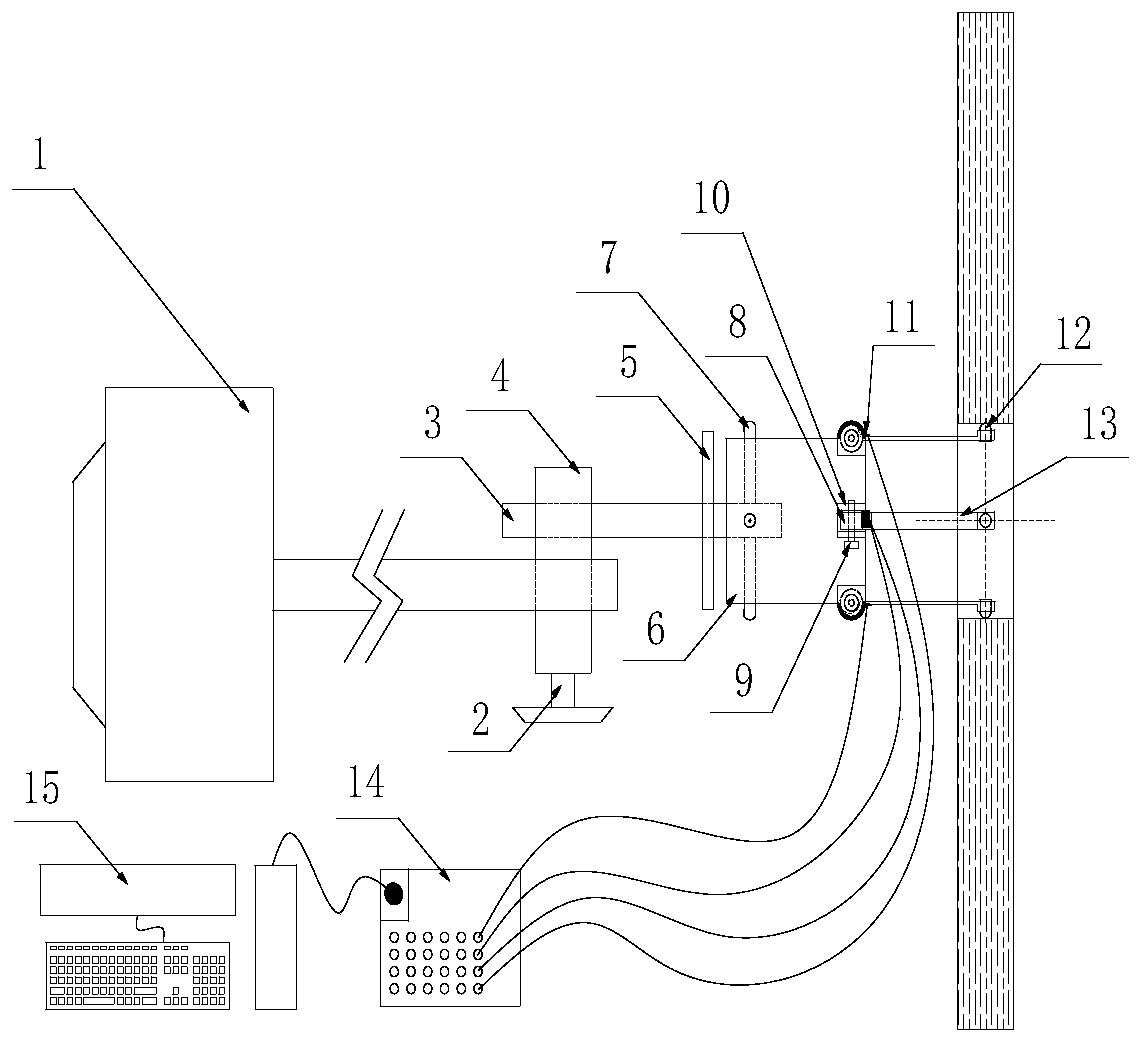

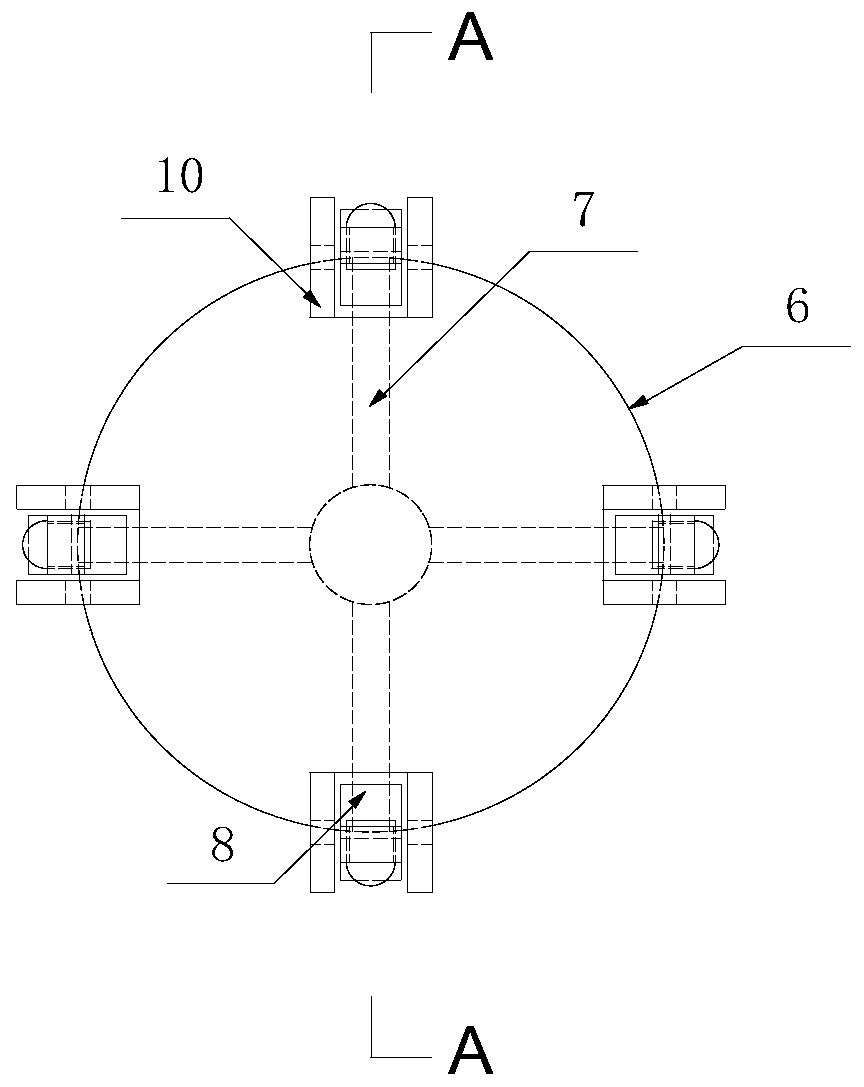

[0028] Attached below figure 1 , attached figure 2 , attached image 3 And attached Figure 4 , the present invention will be further described.

[0029]The radial displacement measurement device for the small-aperture tunnel model test is composed of a magnetic base 1, a radial displacement gauge and a static strain gauge 14. The radial displacement gauge includes a circular connecting rod 3, a cylindrical base 6 and an elastic measuring head , the elastic measuring head is composed of an annular steel seat 8, a spring steel sheet 13 and a measuring head 12; one end of the cylindrical base 6 is provided with four circumferentially symmetrically distributed U-shaped grooves, and the inner walls of each U-shaped groove are symmetrically arranged with stainless steel semicircles The protractor 10, the annular steel base 8 and the stainless steel semicircular protractor 10 on both sides of the U-shaped groove of the cylindrical base 6 are connected by screws 9 to impose rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com