Sic material and sic composite material

A technology of multi-layer composite materials and diffraction intensity, which is applied in the direction of polycrystalline material growth, metal material coating technology, carbon compounds, etc., can solve the problems of SiC material product stability reduction, etc., to improve economy and productivity, increase The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, examples of the present invention will be described in detail. In describing the present invention, if it is judged that the specific description of related known functions or configurations unnecessarily obscures the gist of the present invention, the detailed description will be omitted. In addition, the terms used in the present invention may be different according to the user's intention, the operator's intention, or the practice of the field to which the present invention belongs, as terms used to appropriately express the preferred embodiments of the present invention. In the specification, the definitions of these terms are based on the entire contents of the specification.

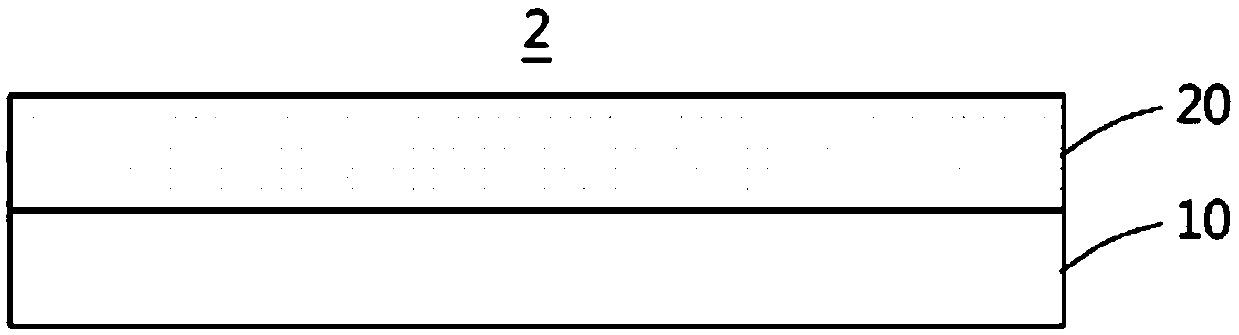

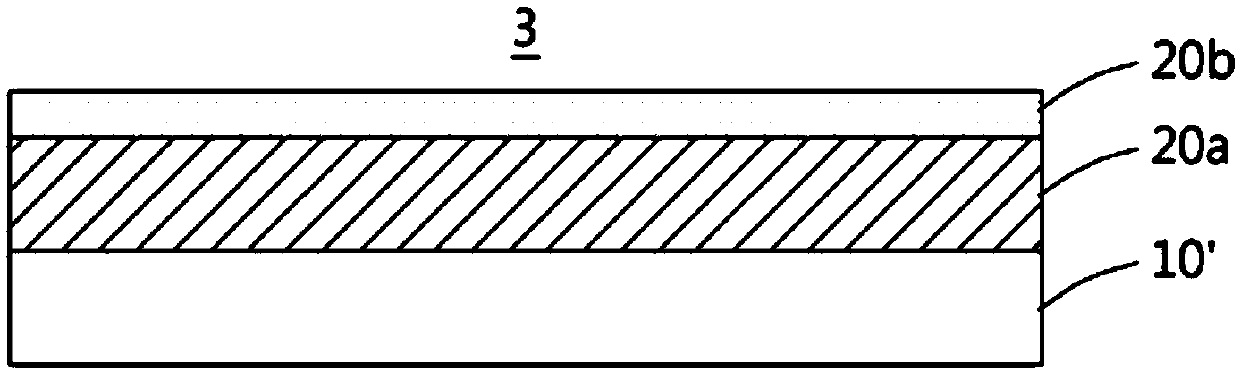

[0038] The present invention relates to a SiC (silicon carbide) material that grows 111 planes in the preferential crystal growth direction of the plasma-exposed surface, and can form a surface with improved stability to a plasma environment and a uniform etching amount.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com