Sealing composition

A sealing composition and composition technology, applied in the direction of phosphorus compound, electrophoretic plating, coating, etc., can solve the problems of poor adhesion to substrates, corrosion formation, difficulty in obtaining uniform coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

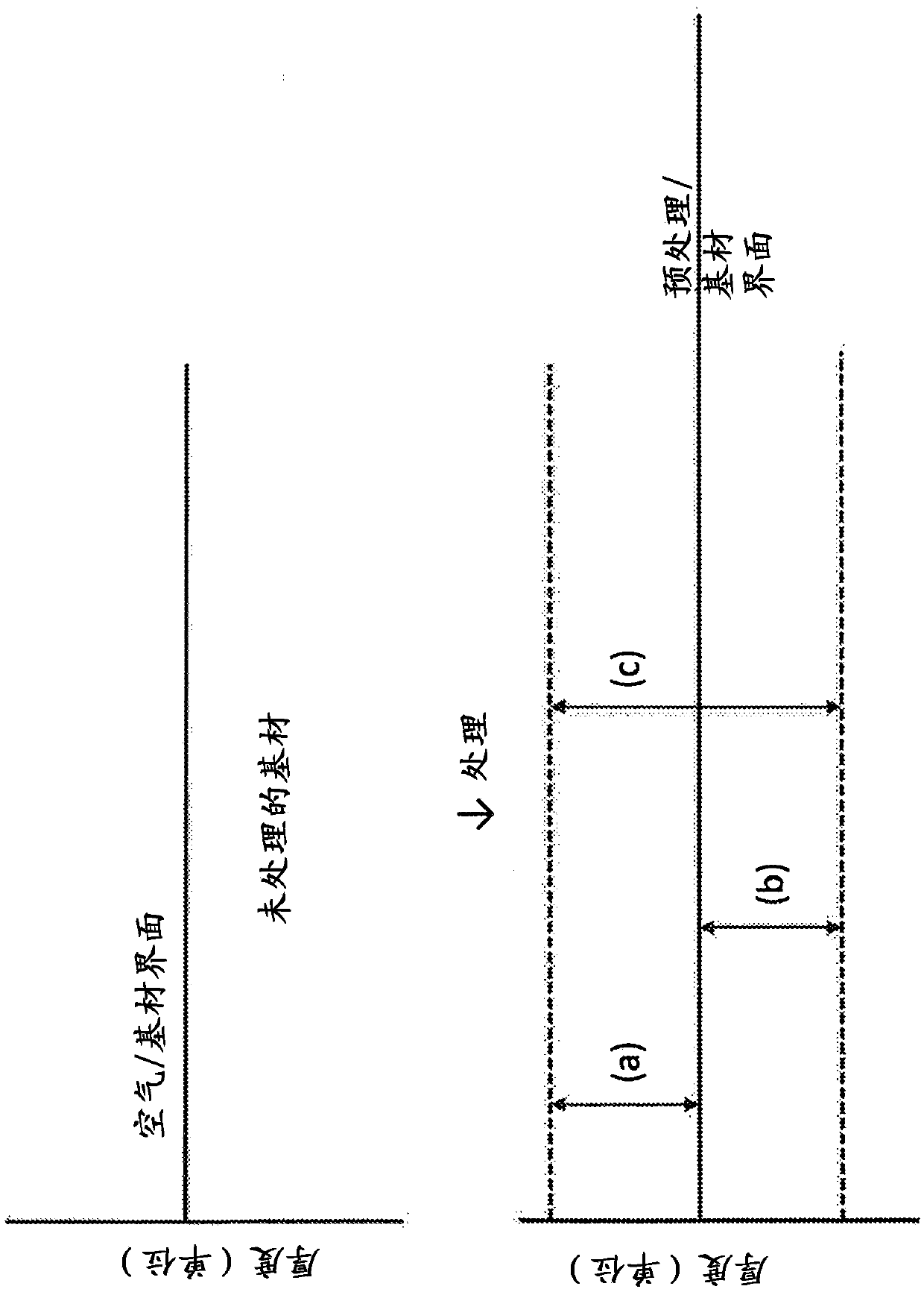

Method used

Image

Examples

Embodiment

[0206] Table 3 - Materials used in Examples 1-5

[0207] Ridoline 298 1

[0208] 1 Non-silicate (non-silicate) cleaning agent.

[0209] 2 Deoxidizer.

[0210] 3 (2,5-dioxo-4-imidazolidinyl)urea.

[0211] 4 Nonionic surfactant.

[0212] *According to the supplier's analysis report, the concentration of cerium in cerium chloride solution is calculated as ceria (CeO 2 ) to measure.

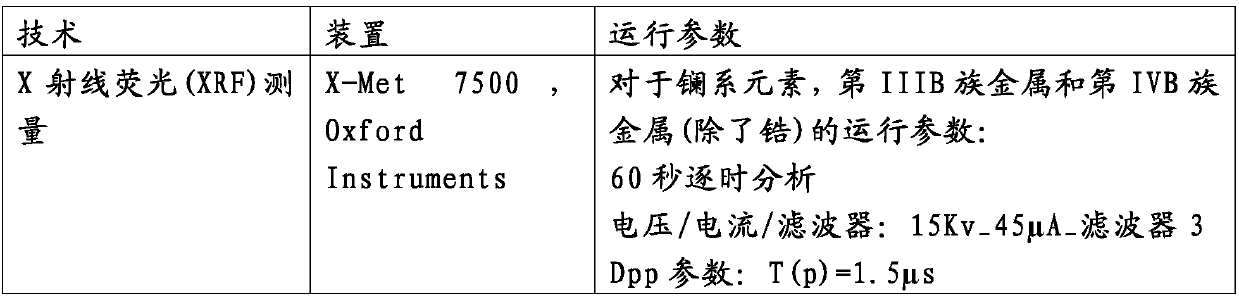

[0213] Table 4 – Devices

[0214]

[0215] Cleaning agent used in Examples 1-8

[0216] Table 5A. - Example A

[0217] Element

[0218] The ingredients used to prepare the solution of Cleaner Example A are provided in Table 5A. Sodium hydroxide and sodium phosphate were completely dissolved in deionized water under gentle mechanical stirring using a stir plate (VWR, 7x7CER HOT / STIR). Next, the PVP was stirred until dissolved, and then the allantoin was added and stirred until dissolved, and then the DMTD was added and stirred until dissolved. After the DMTD ...

Embodiment B

900

[0221] The solution of Example B was prepared according to the manufacturer's instructions using the ingredients shown in Table 5B.

[0222] Table 6 - Deoxidizers used in Examples 4 and 5

[0223] Material

Example C

Deoxidizer 6-16, parts by volume

100

nitric acid, parts by volume

200

Tap water, parts by volume

1700

[0224] The deoxidizer solution of Example C was prepared using the ingredients shown in Table 6 according to the manufacturer's instructions.

[0225] Table 7 - Conversion Coating Compositions Used in Examples 1 and 3-8

[0226]

[0227] The ingredients used to prepare conversion coating compositions E and F are shown in Table 7.

[0228] For the conversion coating composition of Example E, the cerium nitrate, yttrium nitrate and cerium chloride solutions were weighed into individual cups. The solution was then transferred to a container containing 1000 g of deionized water with gentle stirring...

Embodiment 1

[0236] A bare aluminum 2024T3 substrate (Priority Metals, Orange County, CA) measuring 3"x5"x0.032" was hand wiped with methyl ethyl ketone (100%) and a disposable cloth and allowed to air dry, followed by chemical cleaning. The panel was immersed in the cleaner solution of Example A for 3.5 minutes at ambient temperature with intermittent agitation. The panel was then immersed in two subsequent deionized water rinses of 2 minutes each, both at ambient temperature with intermittent agitation After the second rinse, the panel was rinsed with cascaded deionized water for 10 seconds. The panel was then immersed in the conversion coating composition of Example E for 5 minutes at ambient temperature without agitation. After the conversion coating, the The panels received an immersion rinse in deionized water for 1 minute at ambient temperature with intermittent agitation, followed by a 10 second cascade rinse of deionized water.The panels were air dried overnight at ambient conditio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com