Method for preparing metal powder by plasma spheroidizing

A technology of metal powder and spheroidization, which is applied in the field of alloy powder, can solve the problems of powder bulk density and fluidity not reaching the optimal state, and low spheroidization rate, so as to avoid high temperature sintering and product re-oxidation, and smooth surface , The effect of high bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

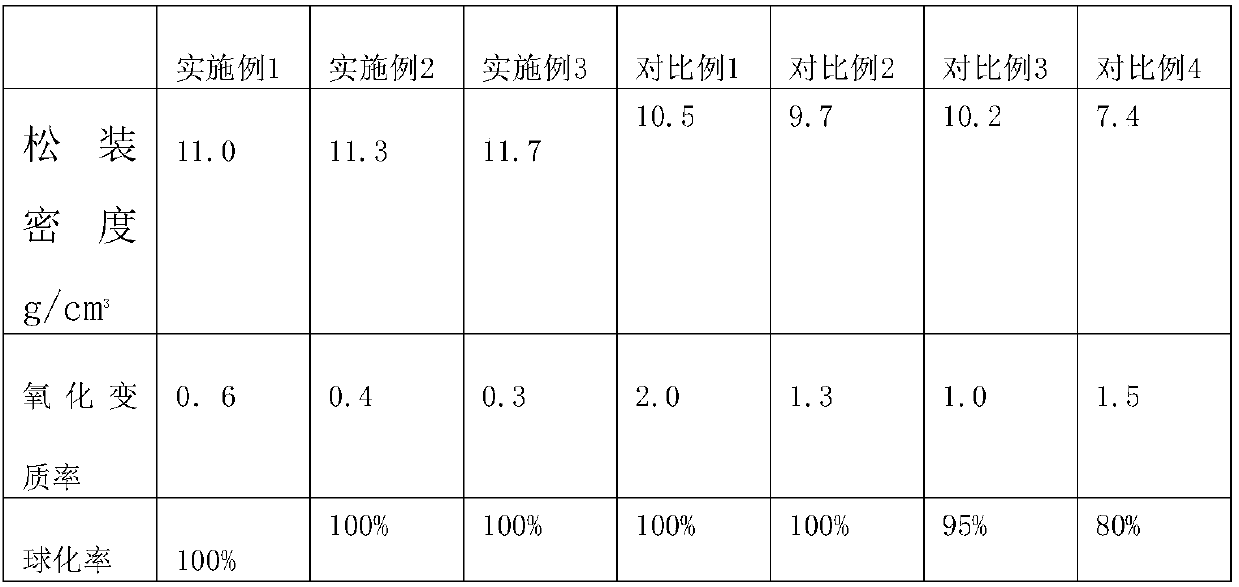

Examples

Embodiment 1

[0050] A method for preparing metal powder by plasma spheroidization, comprising the following steps:

[0051] 1) Send the raw metal powder into a ball mill for grinding to obtain a single particle powder with good dispersibility and uniform particle size distribution, and then fully dry it; the particle size of the metal powder is 60 μm.

[0052] 2) Pre-vacuumize the melting chamber and atomization chamber, and the vacuum degree reaches 2×10 -2 Pa, after the melting chamber is filled with protective gas, the pressure is 0.4MPa, and then filled with argon;

[0053] 3) Metal powder is smelted in a graphite crucible, and the melting temperature is 120°C higher than the melting point of the metal; a metal melt is formed;

[0054] 4) A double-layer atomizing nozzle is used to atomize and hydrogenate the metal melt to make metal powder; the atomizing gas is helium, and the direction of helium injection is at a certain angle to the flow direction of the metal melt, and its range is...

Embodiment 2

[0060] A method for preparing metal powder by plasma spheroidization, comprising the following steps:

[0061] 1) Send the raw metal powder into a ball mill for grinding to obtain a single particle powder with good dispersibility and uniform particle size distribution, and then fully dry it. The particle size of the metal powder is 60-80 μm;

[0062] 2) Pre-vacuumize the melting chamber and atomization chamber, and the vacuum degree reaches 3×10 -2 Pa, after the melting chamber is filled with protective gas, the pressure is 0.5MPa, and then filled with helium;

[0063] 3) The metal powder is smelted in a graphite crucible, and the melting temperature is 130°C higher than the melting point of the metal to form a metal melt;

[0064] 4) A double-layer atomizing nozzle is used to atomize and hydrogenate the metal melt to make metal powder; the atomizing gas is helium, and the direction of helium injection is at a certain angle to the flow direction of the metal melt, and its ran...

Embodiment 3

[0070] A method for preparing metal powder by plasma spheroidization, comprising the following steps:

[0071] 1) Send the raw metal powder into a ball mill for grinding to obtain a single particle powder with good dispersibility and uniform particle size distribution, and then fully dry it; the particle size of the metal powder is 80 μm;

[0072] 2) Pre-vacuumize the melting chamber and atomization chamber, and the vacuum degree reaches 5×10 -2 Pa, after the melting chamber is filled with protective gas, the pressure is 0.60MPa, and then filled with the mixed gas of argon and helium;

[0073] 3) Metal powder is smelted in a graphite crucible, and the melting temperature is 140°C higher than the melting point of the metal; a metal melt is formed;

[0074] 4) A double-layer atomizing nozzle is used to atomize and hydrogenate the metal melt to make metal powder; the atomizing gas is helium, and the direction of the helium gas injection is at a certain angle to the flow directio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com